Compound Vacuum Suction Cup

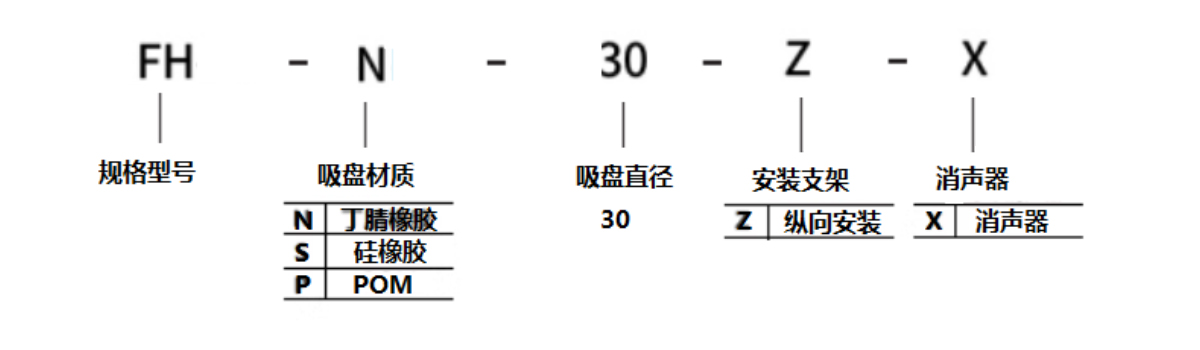

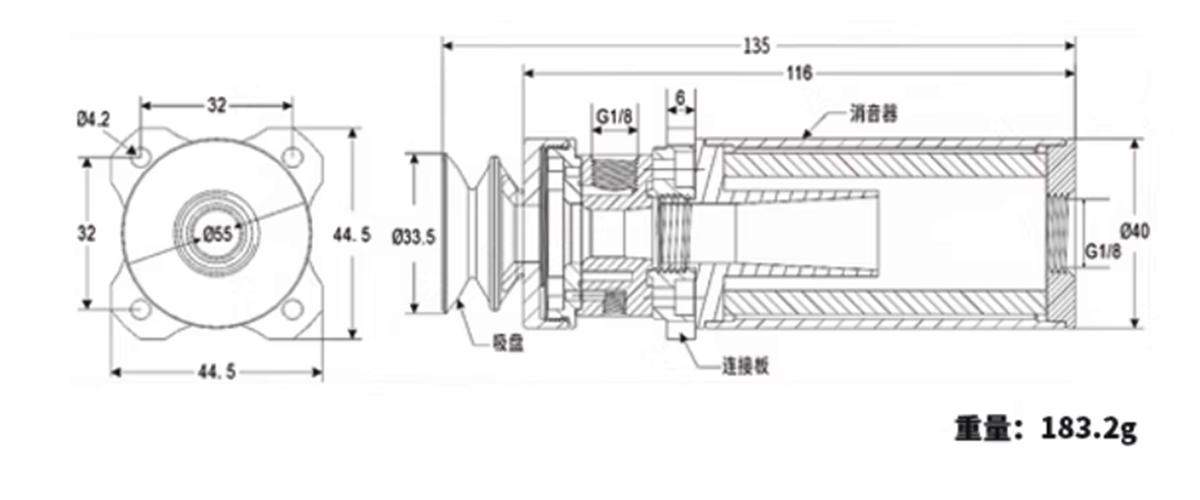

FH Series Composite Suction Cup

The FH series composite suction cup is a highly adaptable vacuum adsorption solution designed for complex industrial scenarios. Its core lies in the integration of multiple material properties and structural mechanics principles. Through integrated design, it achieves stable gripping performance under multi-material, multi-curvature and high-disturbance conditions, meeting the stringent requirements of modern automated production lines for flexible handling.

The main features are reflected in:

Multi-level material composite structure

The laminated composite process of special polymers and reinforced substrates is adopted. The surface layer has high adhesion and wear resistance, and the bottom layer is embedded with a reinforced support structure, taking into account the elastic deformation requirements and overall fatigue resistance, breaking through the physical property limitations of a single material.

Adaptive surface fitting mechanism

The built-in micro-airbag buffer layer and distributed diversion channel can autonomously adjust the local deformation amplitude according to the surface curvature of the workpiece at the moment of contact, significantly improving the vacuum sealing efficiency of irregular geometric bodies (such as stampings, injection molded parts) or micro-arc surfaces.

Turbulence suppression and energy consumption optimization

The flow channel topology is optimized by fluid dynamics. The vortex damping design reduces the gas turbulence loss during high-speed pick-and-place, maintains vacuum stability under low flow conditions, and simultaneously reduces energy consumption and system noise.

Redundant sealing guarantee architecture

Adopting a multi-level boundary seal ring nesting layout, the secondary sealing layer immediately activates vacuum compensation when the main sealing area fails, effectively dealing with the risk of local leakage caused by oil, debris or slight damage on the workpiece surface, and improving the system's fault tolerance.

Modular quick replacement interface

The standardized degree docking base supports tool-free disassembly and assembly of the main body and functional components, making it easy to replace the suction cup module or independently maintain the damaged unit according to the production line requirements, greatly reducing downtime and spare parts management costs.