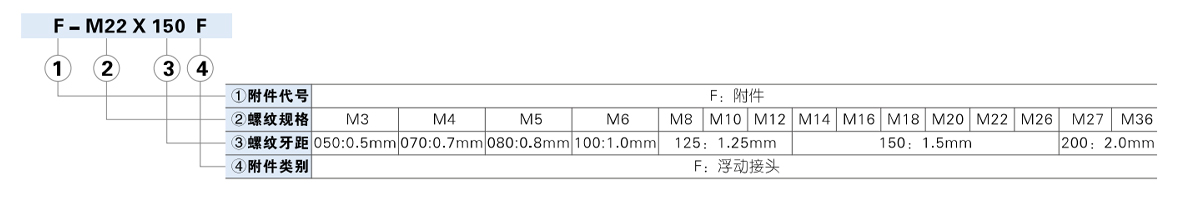

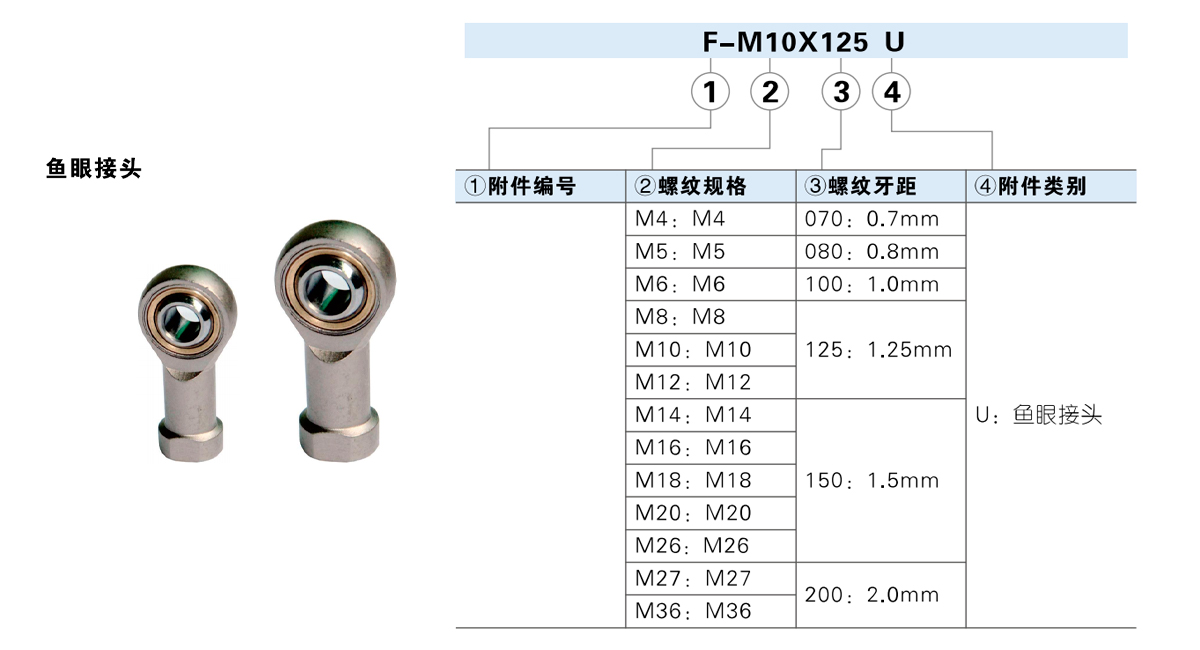

Cylinder Accessories

Cylinder Accessories

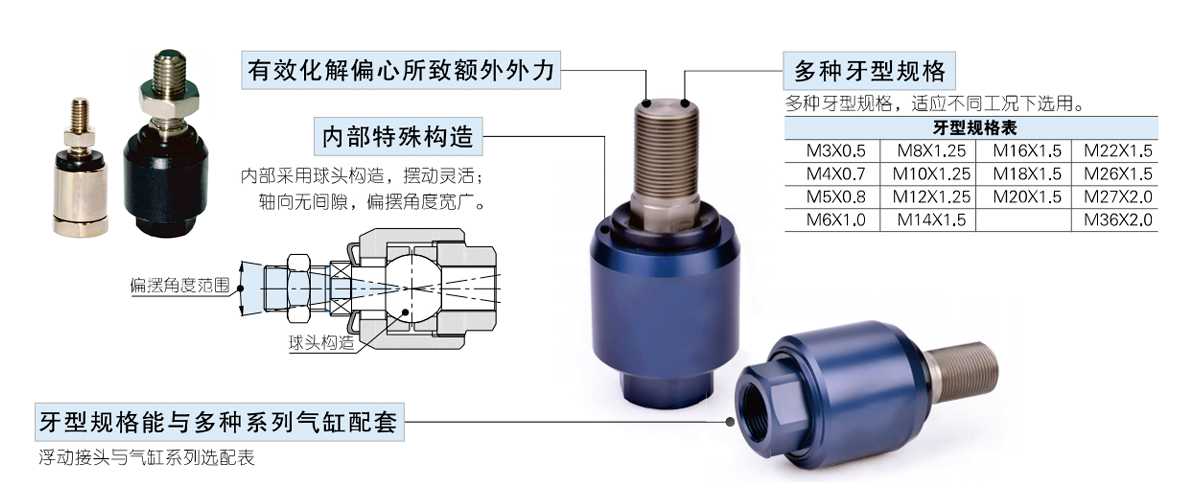

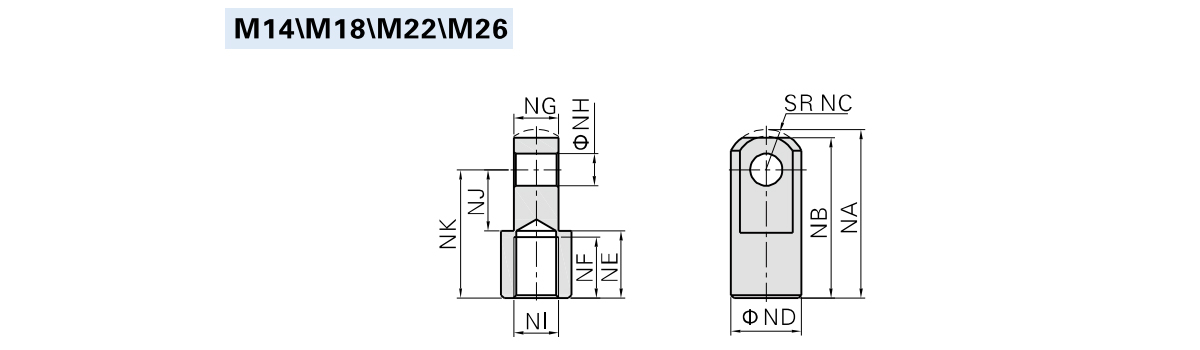

Cylinder Accessories are core supporting components of the cylinder system. Their scientific selection plays a decisive role in ensuring the reliability, control accuracy, service life and operating efficiency of the cylinder. This series of accessories can comprehensively improve the comprehensive performance of the cylinder under various working conditions, reduce maintenance costs, and is suitable for high-precision automated production scenarios through high-strength materials, precision processing technology and optimized structural design.

Core Features

1. High reliability: Made of high-strength alloy forging, it can withstand 1.6MPa working pressure and ±5% pressure fluctuation; oil-resistant nitrile rubber and polytetrafluoroethylene composite sealing components can achieve more than 8000 hours of leakage-free operation in the temperature range of -30℃ to 120℃, significantly reducing the risk of downtime.

2. Precision control: The matching tolerance reaches IT5 level, the end face runout is ≤0.01mm/m, ensuring that the coaxiality error between the cylinder and the load is ≤0.02mm, the piston movement straightness deviation is controlled within 0.05mm/100mm, and the repeat positioning accuracy reaches ±0.01mm.

3. Ultra-long life: Surface hard chrome plating treatment (hardness above HV700), sliding friction coefficient as low as 0.08, with self-lubricating bearings, wear ≤0.001mm/100,000 movements, more than 3 million trouble-free cycles can be achieved under rated conditions, and the life is 3 times longer than that of ordinary accessories.

4. High efficiency and energy saving: The streamlined airflow channel reduces the drag coefficient along the way by 30% and increases the gas response speed by 20%; the lightweight aluminum alloy material (density 2.7g/cm³) reduces the inertia of movement, and the energy consumption is reduced by 15% under high-speed conditions (1m/s), which improves the efficiency of the production line.