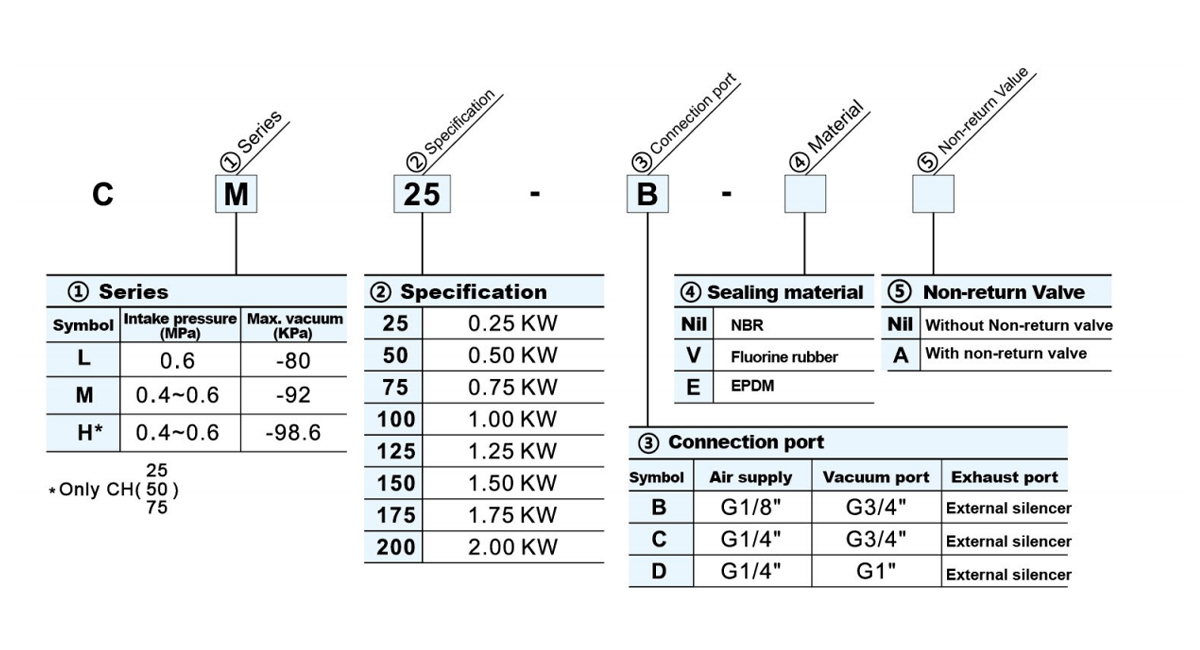

Multistage Vacuum Generator

C Series Multistage Vacuum Generator

C Series Multistage Vacuum Generator is a type of device that uses compressed air to drive and generate vacuum through a special flow channel structure design. Its core principle is the local low-pressure effect caused by high-speed airflow, which is particularly suitable for industrial automation scenarios that require an efficient and compact vacuum source and do not require a traditional vacuum pump.

Hierarchical energy conversion architecture:

Different from a single-stage generator, this series adopts a multi-stage series precision flow channel design. Compressed air expands and accelerates in each chamber one by one, and through the superposition of the progressive gas expansion effect and the Venturi effect, a more complete and gradient utilization of the airflow energy is achieved, thereby obtaining a stronger vacuum suction capacity under the same air supply conditions.

Optimized geometry and flow field characteristics:

The internal flow channel has been specially topologically optimized, including a converging nozzle, a mixing chamber, and a gradually expanding diffusion section. This geometric configuration can effectively guide the airflow to form a high-speed jet, maximizing the strength and stability of the formation of the local low-pressure zone. The specific contours of key parts promote the efficient entrainment and transportation of gas molecules.

Significant balance between efficiency and gas consumption:

The multi-stage energy extraction mechanism is the core of its high efficiency. By decomposing a single gas expansion process into multiple energy steps, the vacuum degree or pumping rate that can be generated per unit of compressed air consumption is significantly improved. This makes the overall gas consumption usually better than that of a conventional single-stage generator when achieving the same vacuum performance, reflecting better operating economy.

Reliable vacuum steady-state output:

The multi-stage structure itself has a certain buffering and regulating effect. When facing slight fluctuations in load or slight changes in gas supply pressure, the output vacuum level shows stronger robustness, providing a more stable negative pressure guarantee for automated grasping, adsorption and other processes.

Compact topology and load adaptability:

Despite the complex internal structure, its overall package remains compact and easy to integrate into space-constrained equipment layouts. Its pumping characteristics enable it to better adapt to load systems with different leakage rates or that require rapid vacuum formation, especially for processing workpieces with porous and irregular surfaces.