Vacuum Regulator

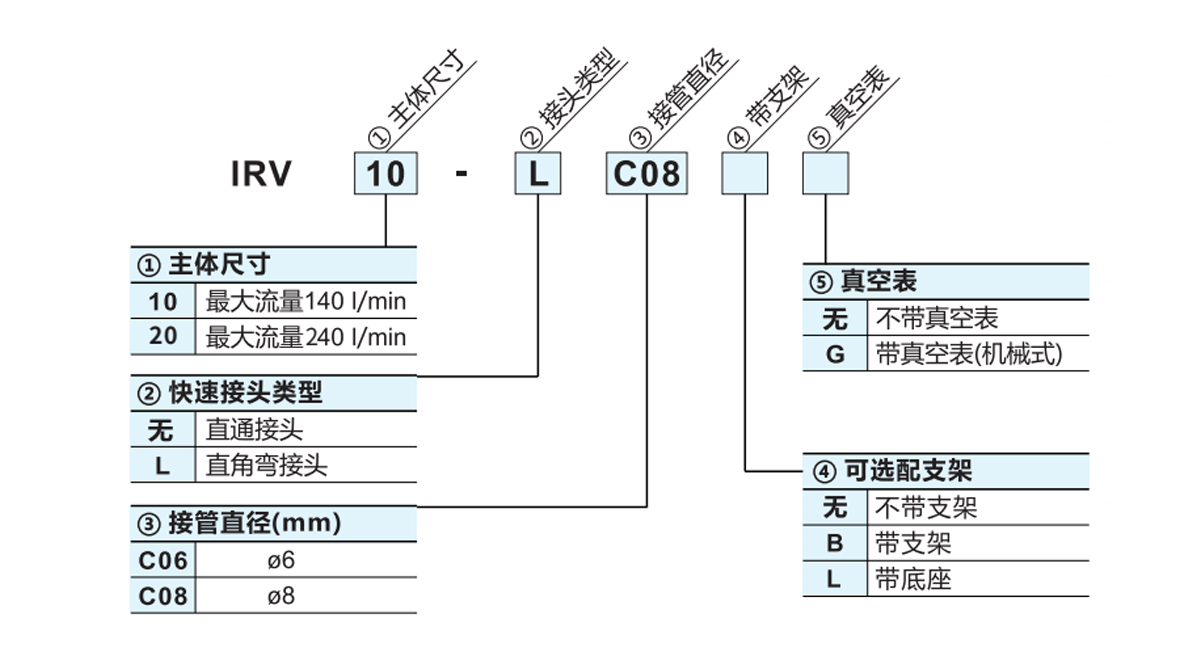

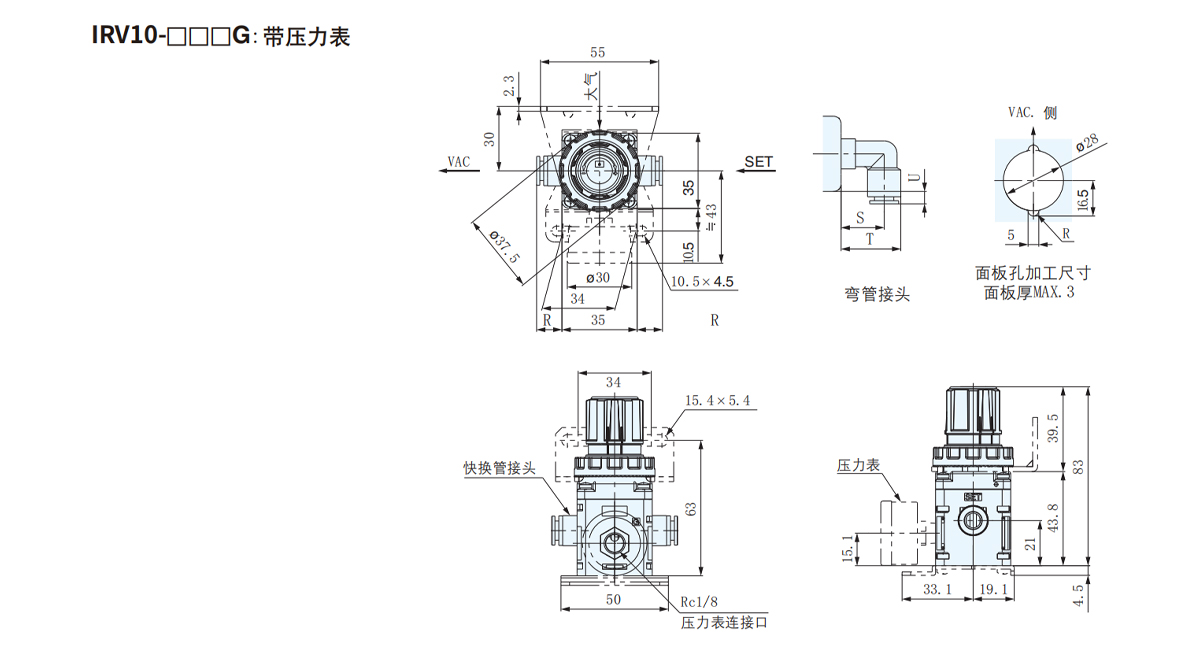

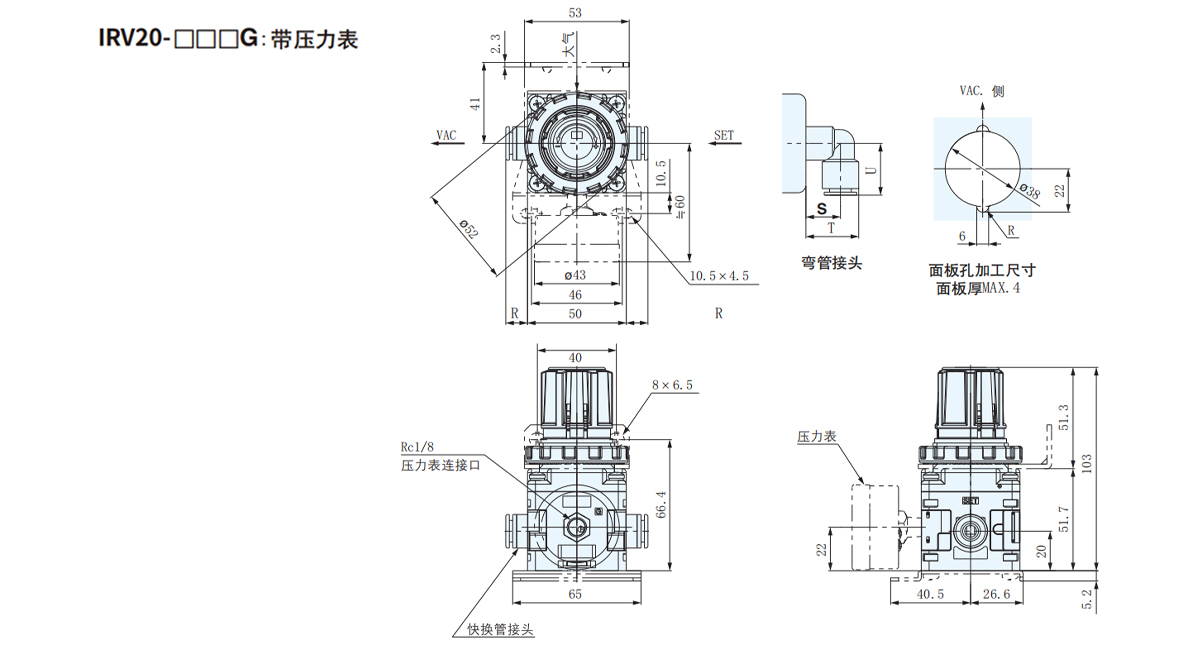

IRV Series Vacuum Control Valve

IRV Series Vacuum Control Valve is a core component dedicated to dynamic pressure control of vacuum systems. Through precise structural design, it realizes stable control and automatic adjustment of system working pressure, ensuring the reliability and repeatability of vacuum process environment.

▸Core functional principle

Based on force balance and feedback mechanism, it uses sensitive elements to sense vacuum pressure changes, drives the valve opening to adaptively adjust, realizes dynamic throttling of gas flow, and maintains the preset pressure value of the system.

▸Structural characteristics and advantages

The metal bellows or special diaphragm sealing structure is used to completely avoid the leakage risk caused by traditional packing seals and ensure long-term sealing stability in high vacuum environments. The integrated casting valve body strengthens rigidity and reduces vibration interference.

▸Working condition adaptability

Built-in corrosion-resistant materials and special surface treatment options are compatible with corrosive process gases and particulate environments. The wide pressure adjustment range design can cover the multi-gradient pressure control needs from rough vacuum to medium and high vacuum.

▸System integration compatibility

The standard flange interface matches the mainstream vacuum chamber specifications, and the electrical interface supports analog signals or digital communication protocols, which is convenient for access to PLC or central control systems to achieve remote closed-loop control and simplify the integration process of automated production lines.

▸Typical application scenarios

It is widely used in semiconductor thin film deposition, vacuum brazing furnaces, precision optical coating, medical device sterilization and other process links that are sensitive to pressure stability, and is often used in conjunction with vacuum gauges to form a high-precision pressure control system.

▸Core value of operation and maintenance

The modular design reduces maintenance complexity, and key components can be replaced independently. Compared with manual valves, it greatly improves process consistency, indirectly improves product yield and reduces energy loss by reducing pressure fluctuations.