ZL Series Multistage vacuum generator

ZL112 Series Multistage Vacuum Ejector

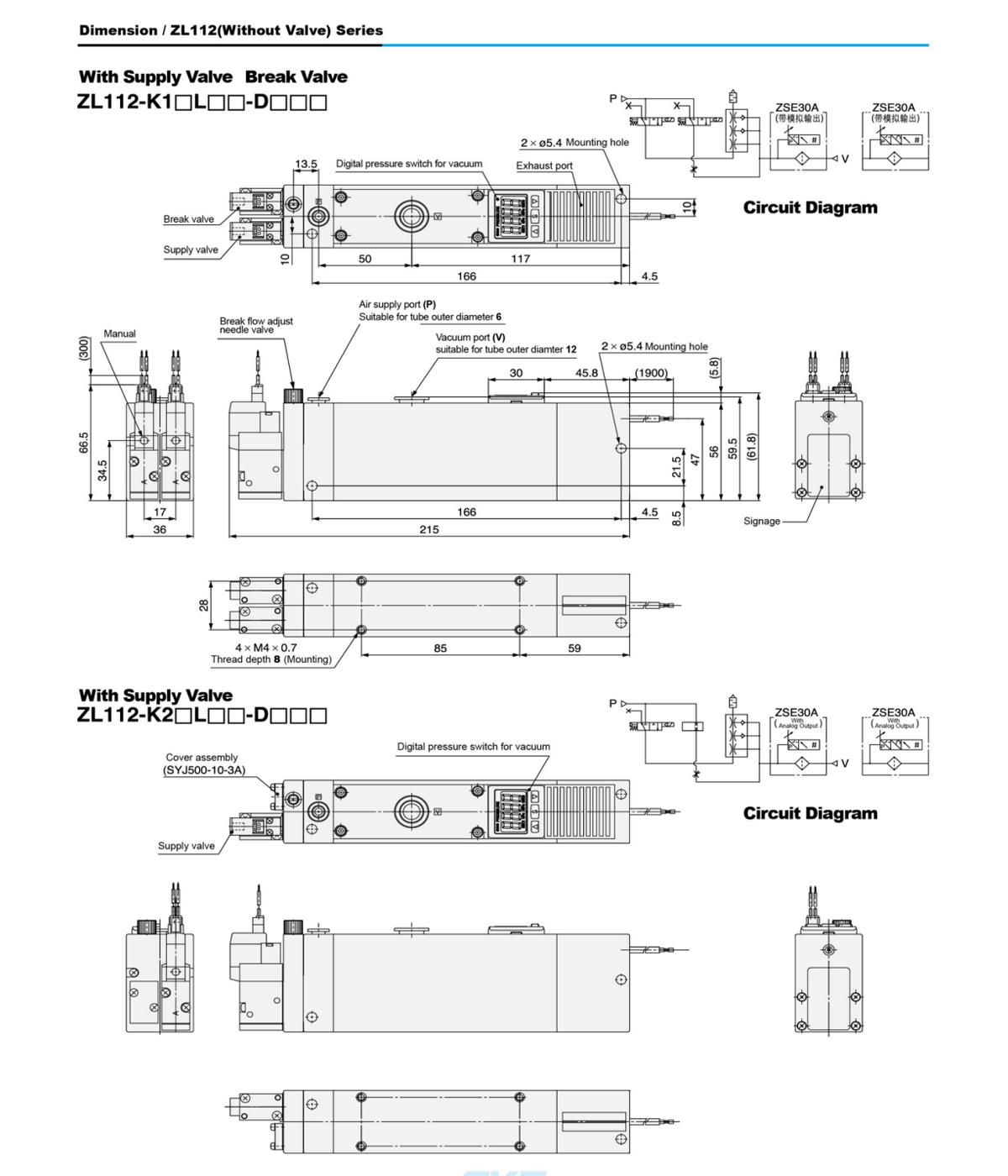

ZL112 Series Multistage Vacuum Ejector adopts a high-efficiency multi-stage structure design, which achieves fast vacuum generation and energy-saving operation by optimizing airflow dynamics. Its core lies in combining compact, lightweight body and modular functions to adapt to the high-frequency and high-reliability vacuum adsorption needs of industrial automation, and is suitable for scenes such as electronics, packaging, and automotive parts handling.

Core Features

Multi-stage expansion technology

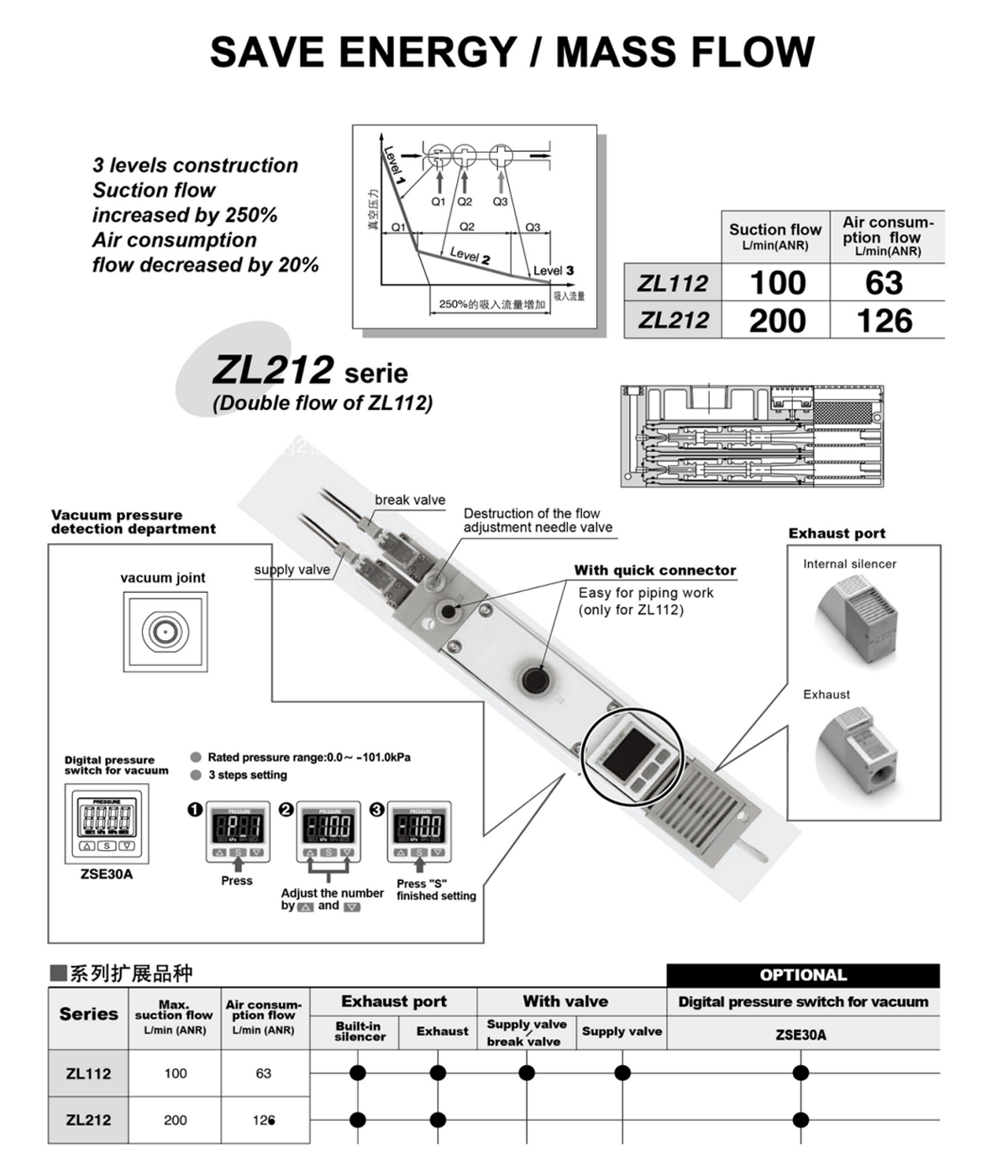

The three-stage Laval nozzle series structure is adopted to significantly improve the suction efficiency through segmented pressurization. Compared with the single-stage nozzle solution, its suction flow rate is increased by about 250%, while the compressed air consumption is reduced by 10%~20%, taking into account large flow demand and energy consumption control.

Integrated energy-saving system

Optional vacuum pressure switch (such as ZSE20A) supports real-time adsorption status monitoring and automatic start-stop control. For example, when the set vacuum value is reached, the supply valve is automatically closed to reduce invalid gas consumption, with a comprehensive energy saving effect of more than 90%, and the response cycle is shortened to milliseconds.

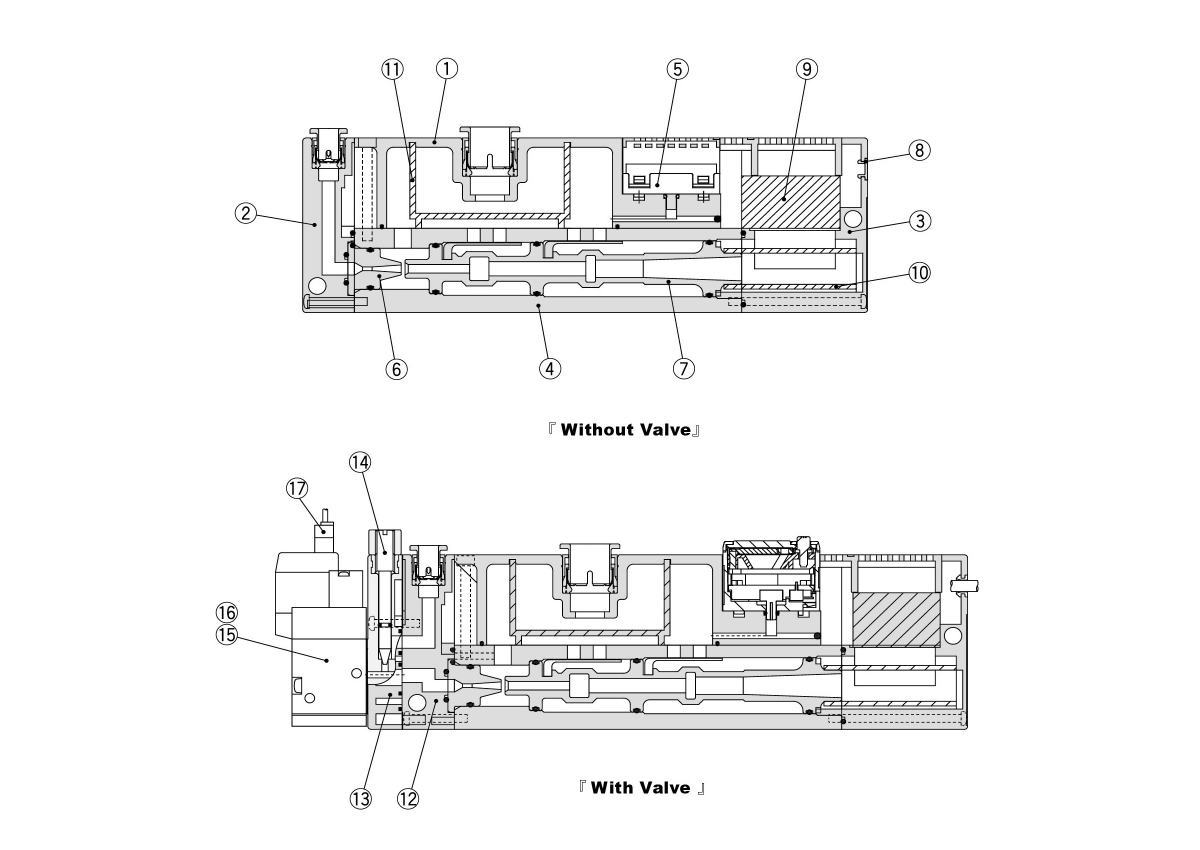

Lightweight modular design

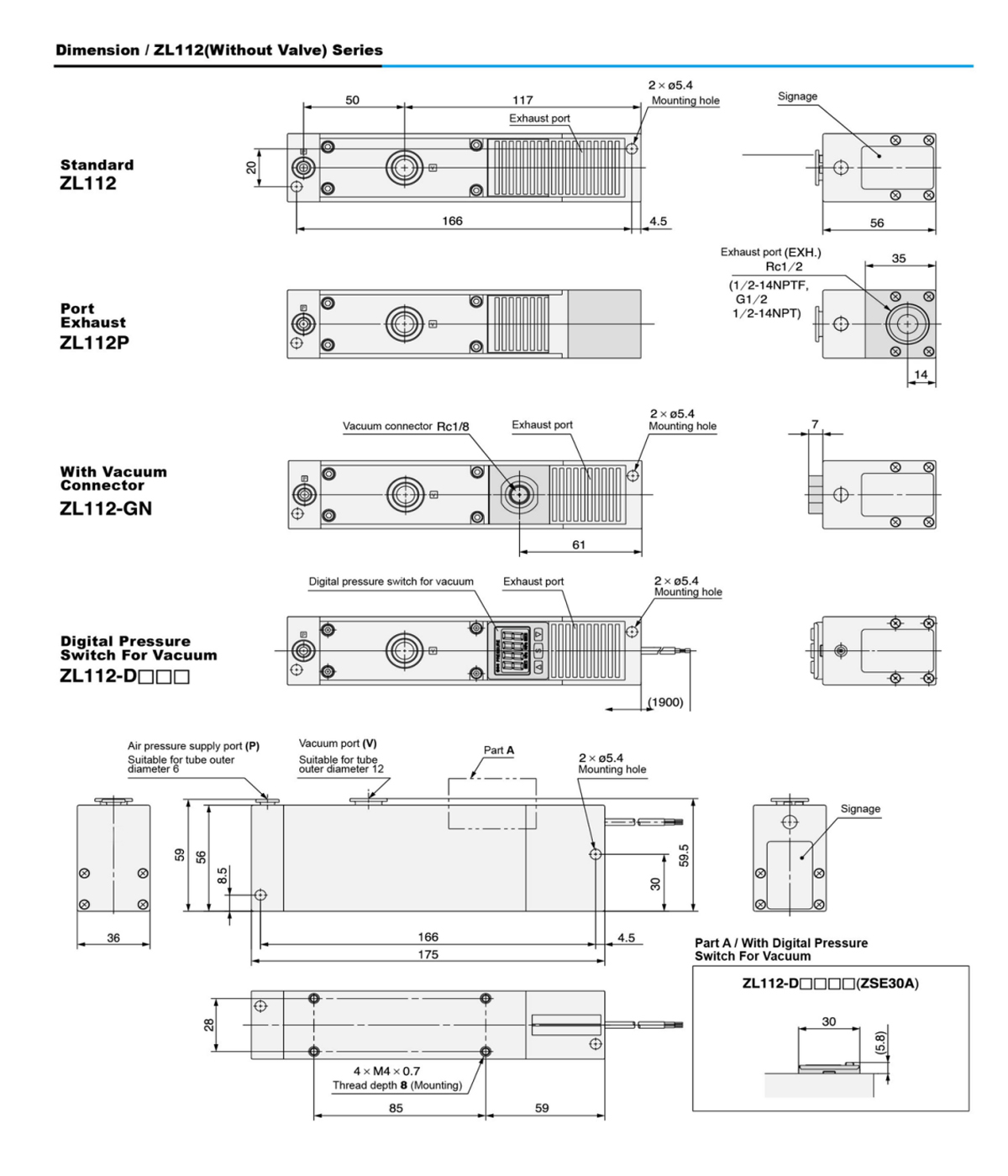

The weight of the machine body is 60% lighter than that of the previous generation (some Models are only 180g), and built-in mufflers, vacuum filters and other components reduce the complexity of external piping. It supports tool-free disassembly and assembly, and the convenience of maintenance is significantly improved.

Functional optimization

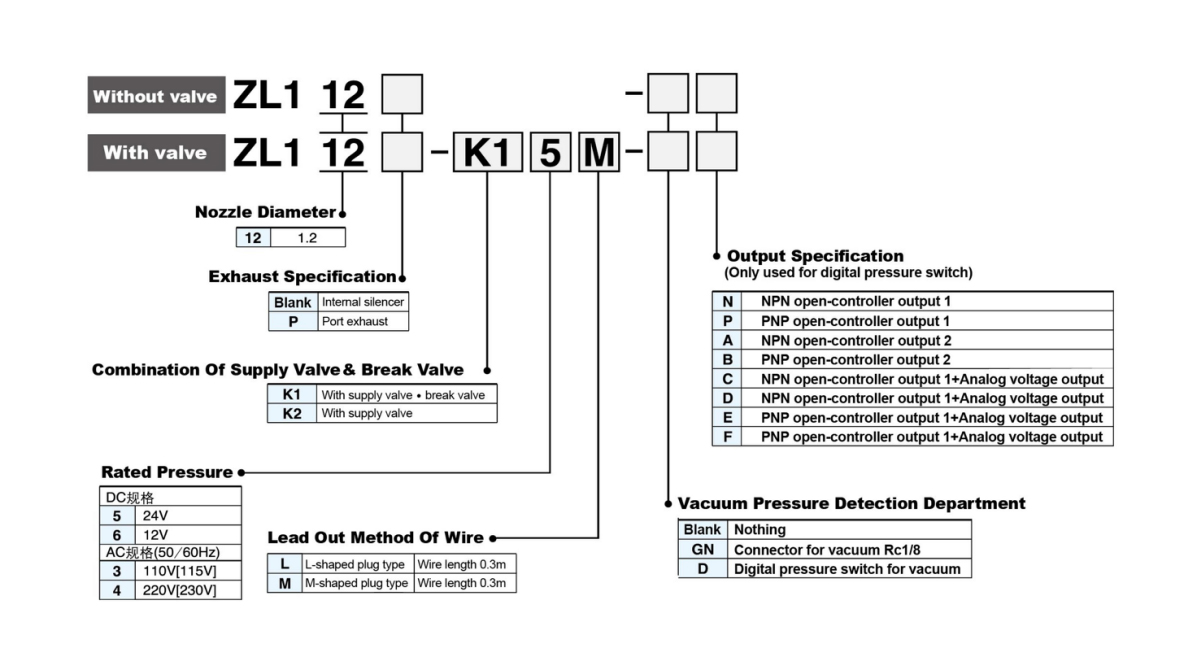

Compatibility and scalability: It provides branch ports, valves/valveless, digital switches and other combination specifications, adapts to the pressure range of 0.2-0.7MPa, and supports IO-Link communication unified parameter management.

Environmental adaptability: The aluminum shell is corrosion-resistant, the operating temperature covers 5-50°C, and the built-in special muffler reduces exhaust noise, which meets the requirements of clean environment applications.