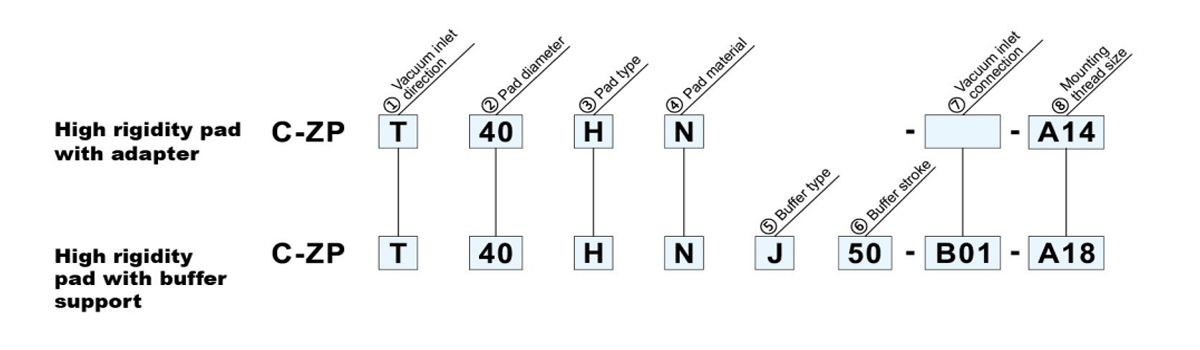

ZP Series Heavy Duty Vacuum Suction Cup, Adapter & Buffer Bracket

ZP Series Heavy Duty Vacuum Suction Cup With Adapter & Buffer Bracket (Ø32~Ø340)

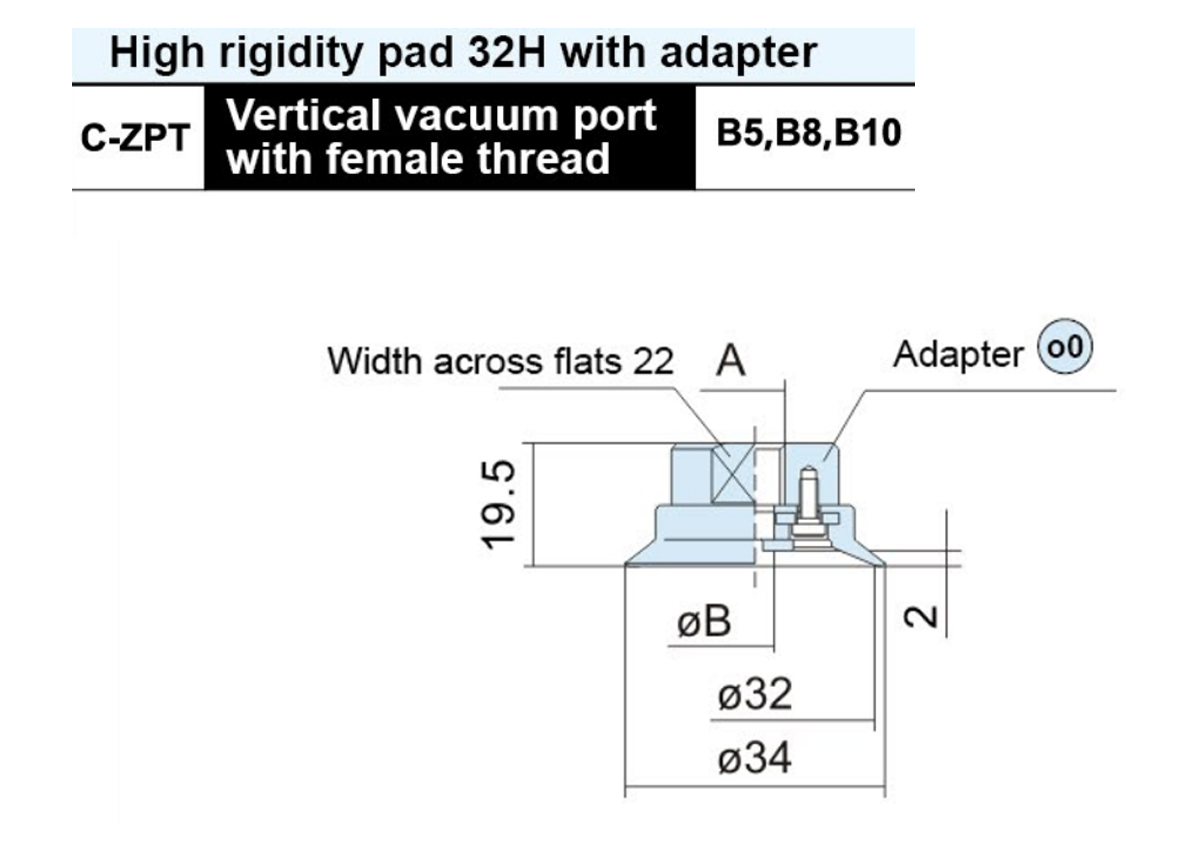

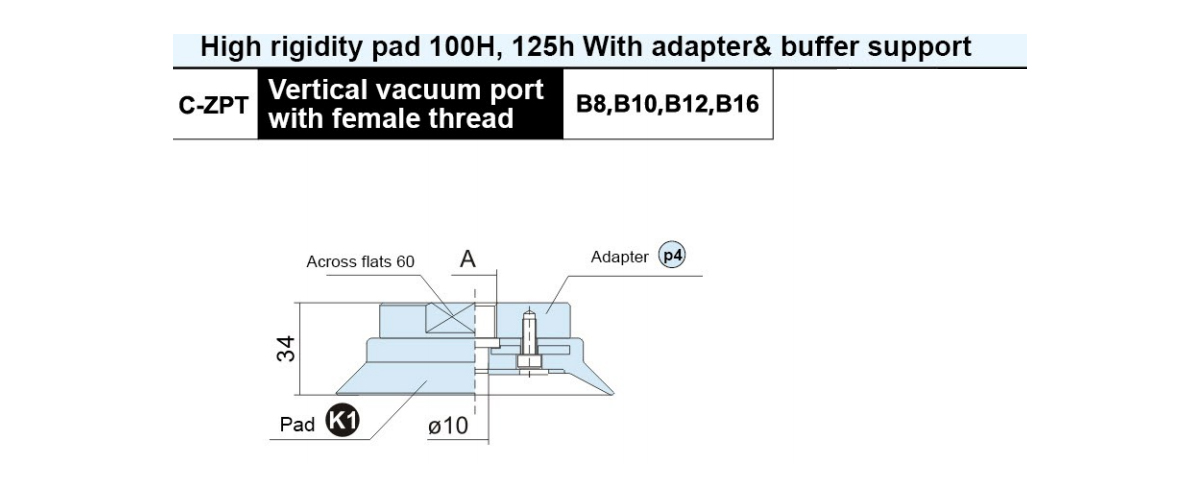

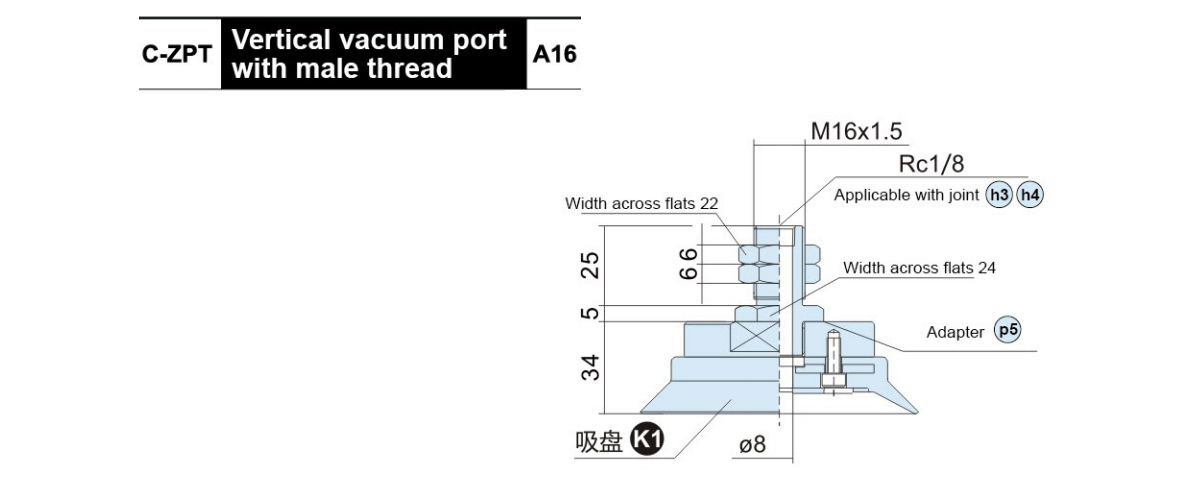

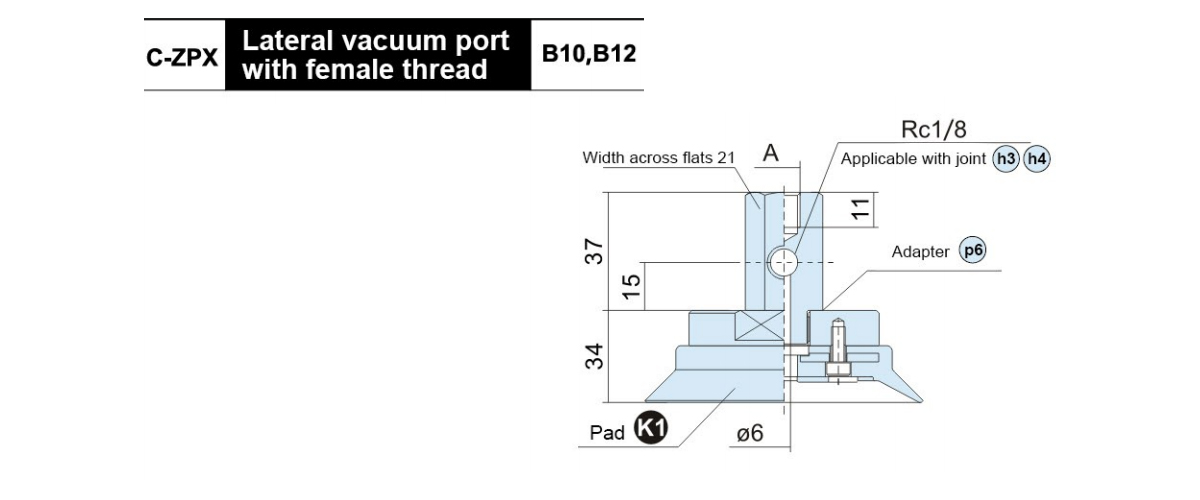

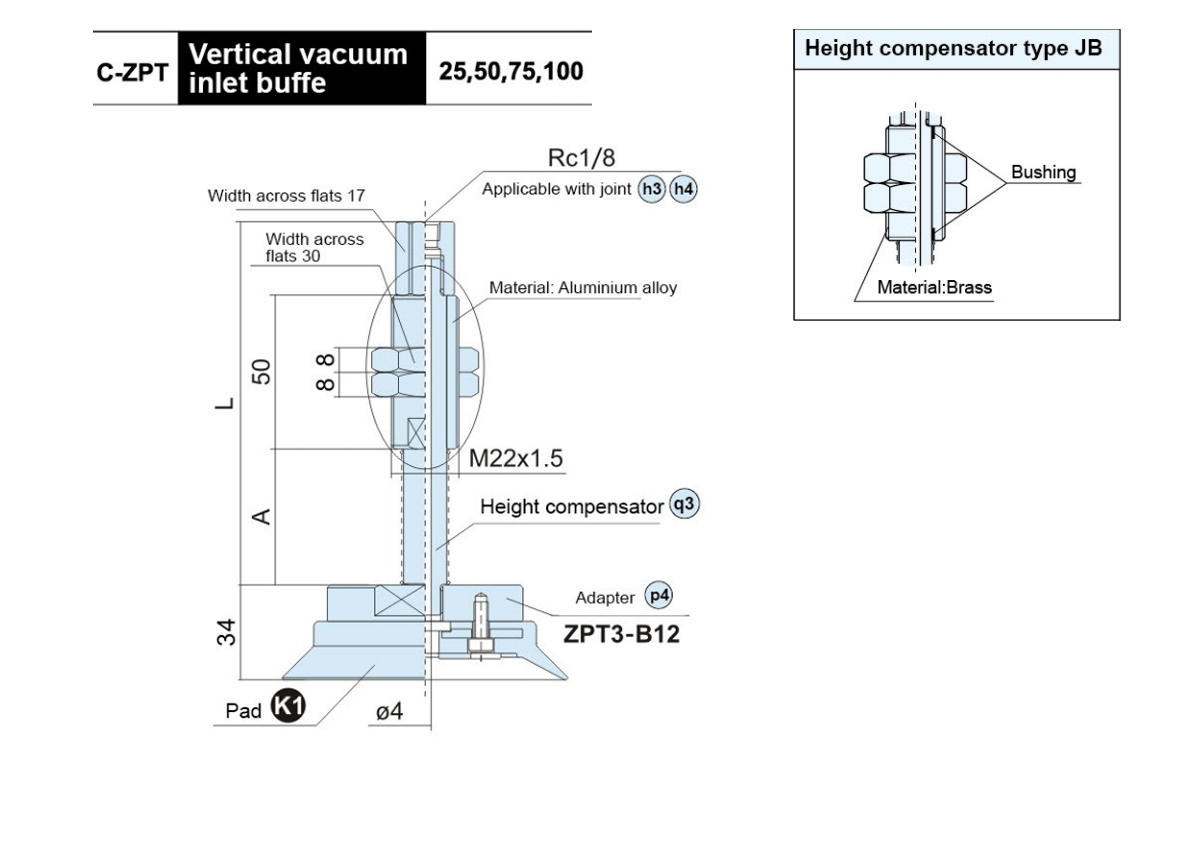

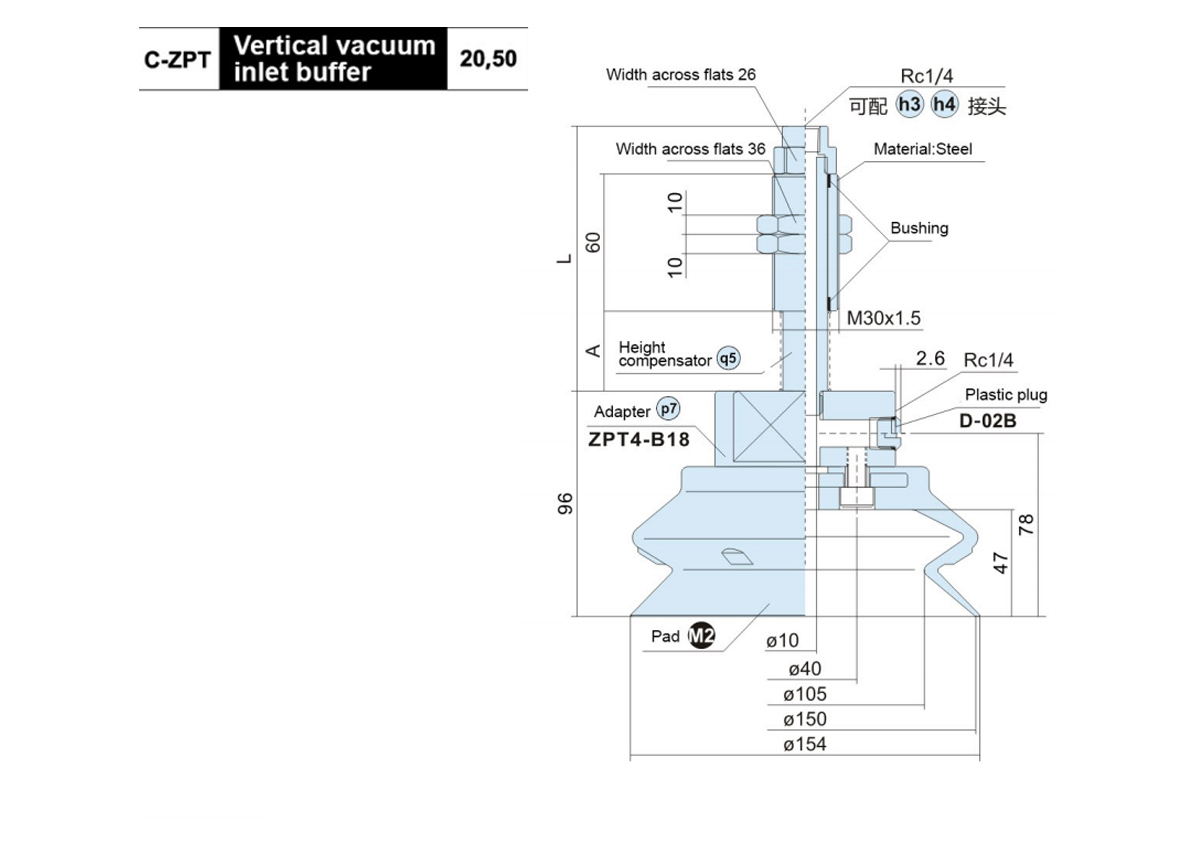

ZP Series Heavy Duty Vacuum Suction Cup With Adapter & Buffer Bracket (Ø32~Ø340) represents an integrated vacuum handling solution designed to meet the demanding industrial gripping needs. It integrates the core heavy-duty suction cup, key interface adapter and required buffer bracket into one, covering a wide range of sizes, and is designed to provide a reliable and adaptable vacuum gripping base unit for handling heavy, irregular or smooth workpieces.

Core Features:

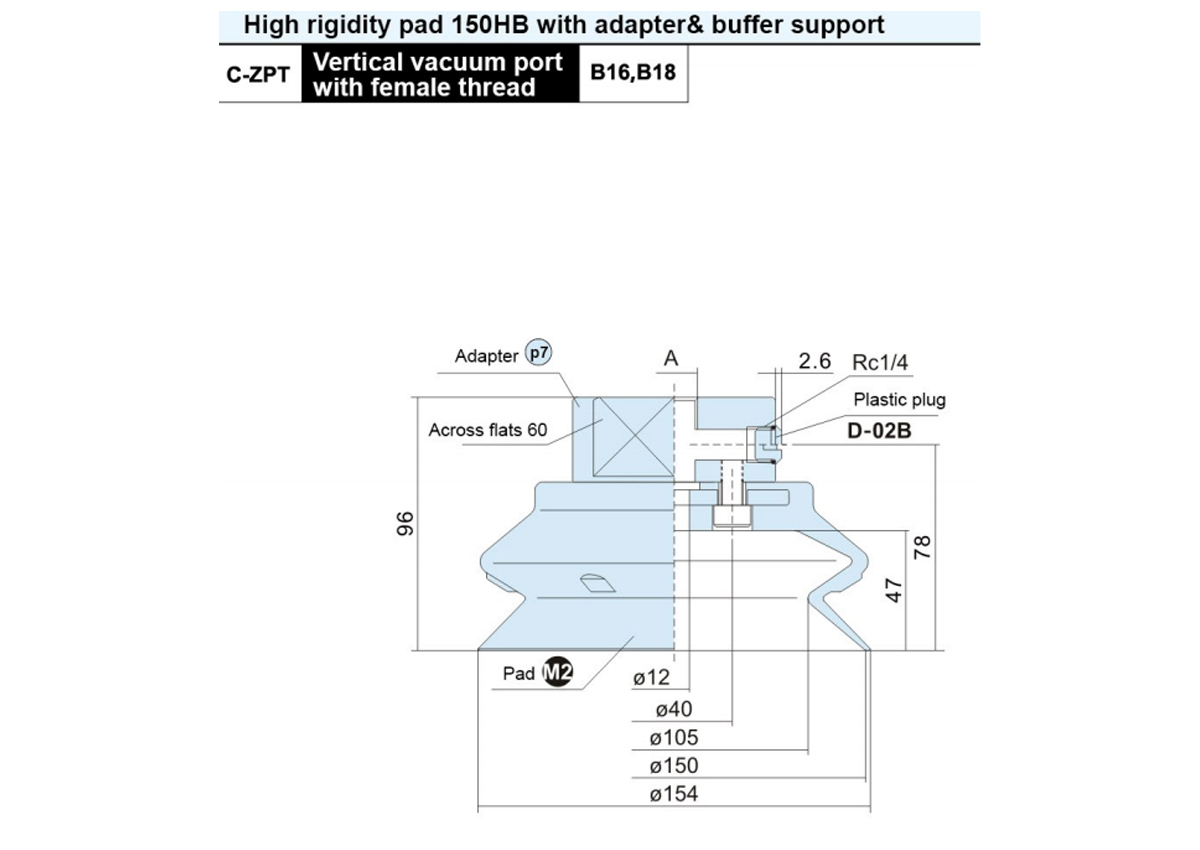

Adaptability to high-load conditions: The core design concept revolves around raising the upper limit of the load bearing capacity of the vacuum system to meet the heavy workpiece handling needs beyond the capacity of ordinary suction cups and meet the strength challenges of industrial sites.

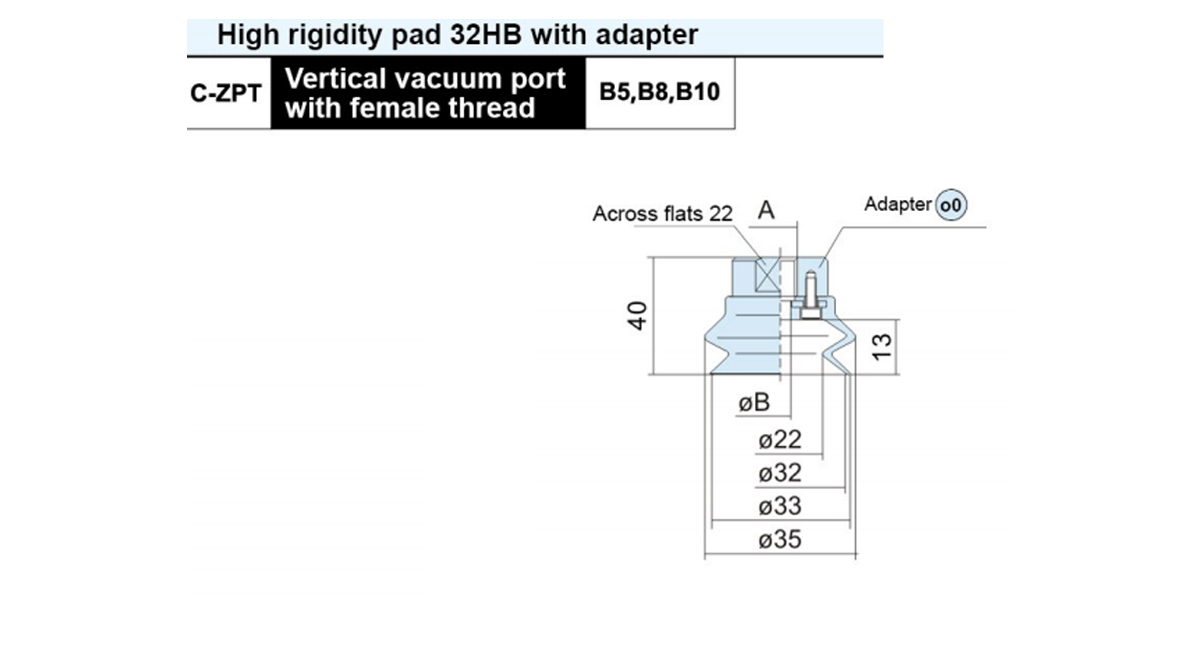

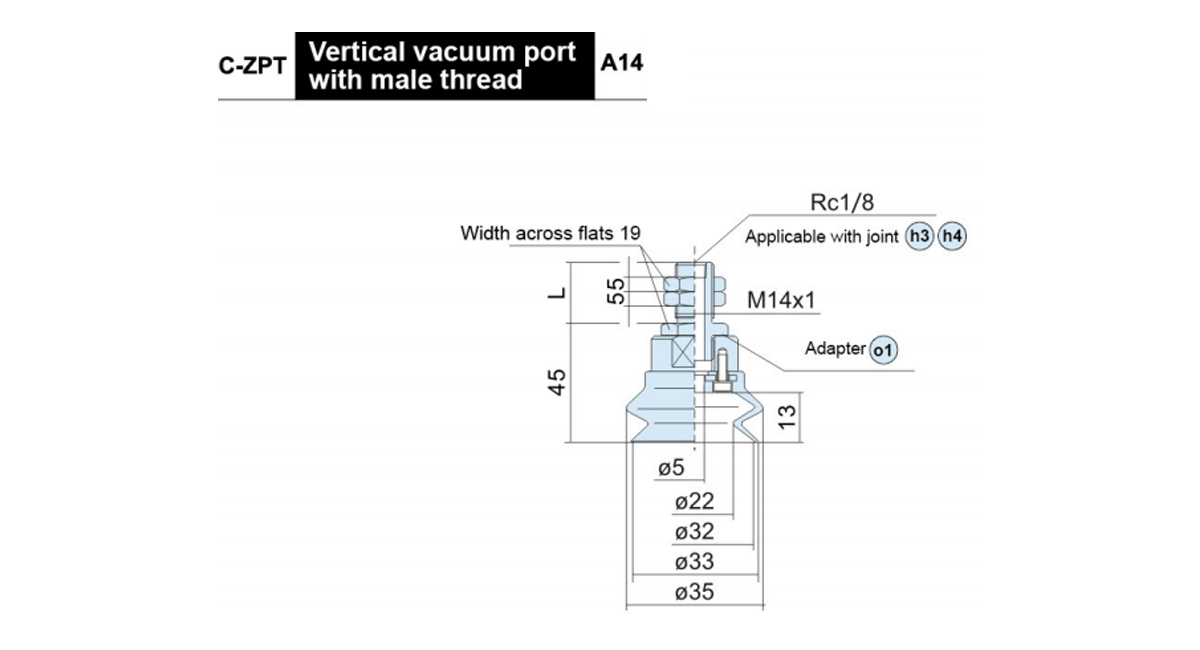

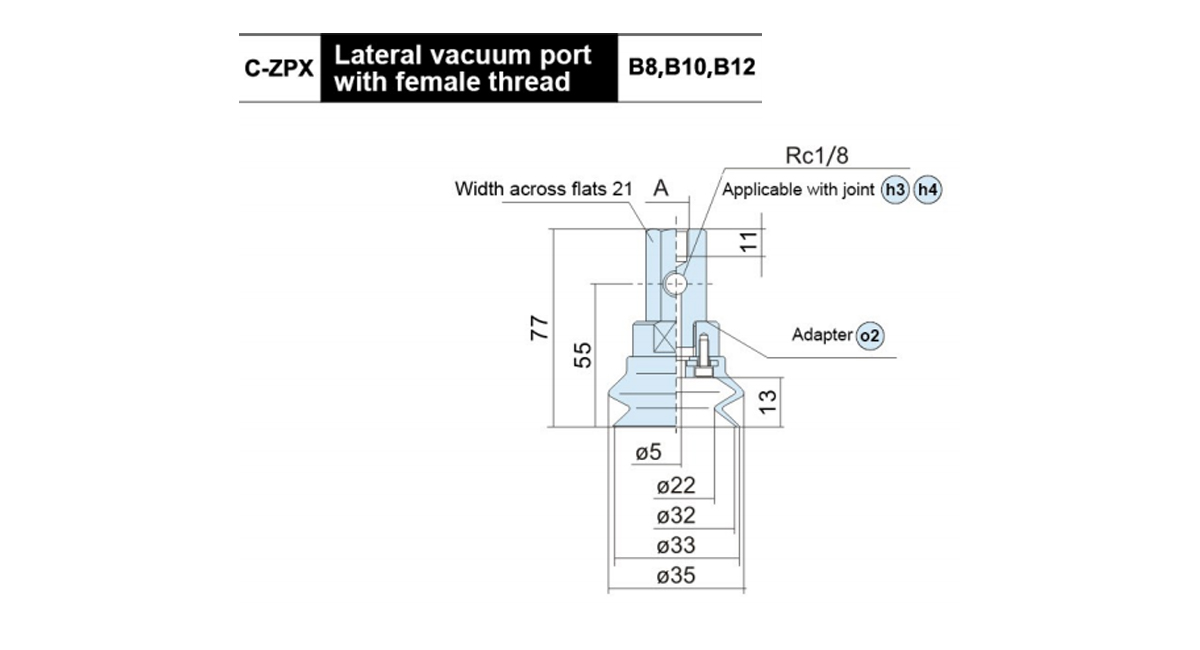

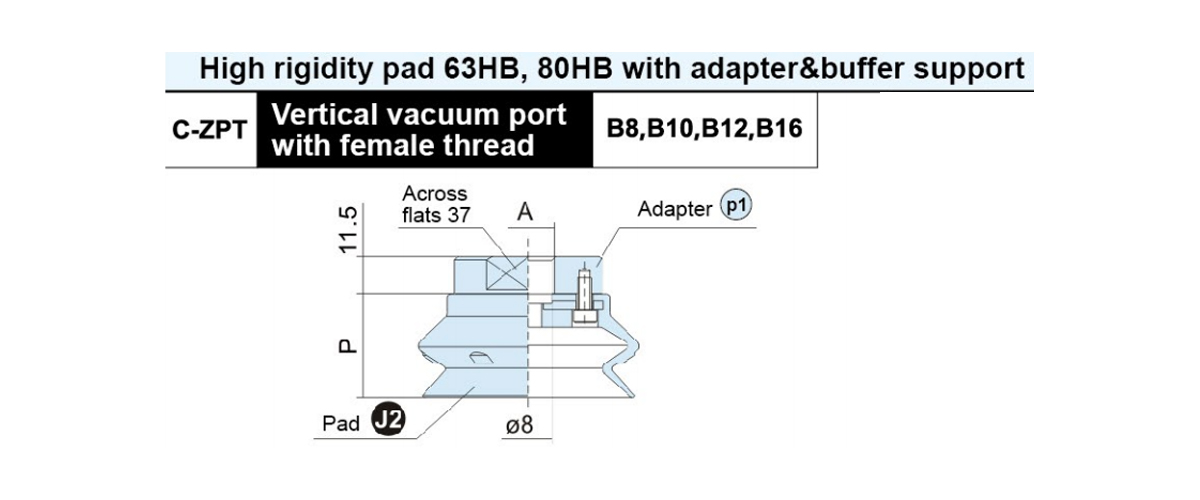

Wide size spectrum coverage: Provides a variety of suction cup body options from smaller sizes to ultra-large areas (covering the range of Ø32 to Ø340), which can flexibly match different workpiece sizes, contours and weight distribution requirements.

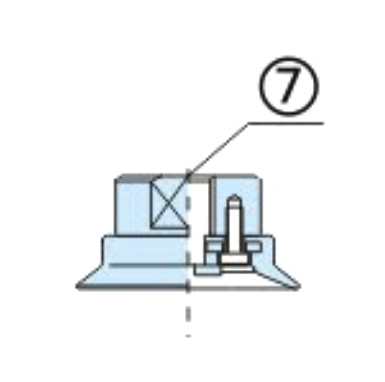

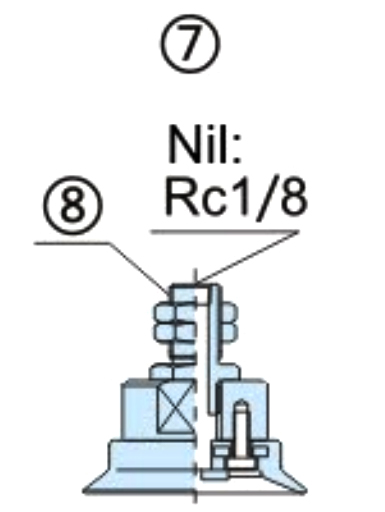

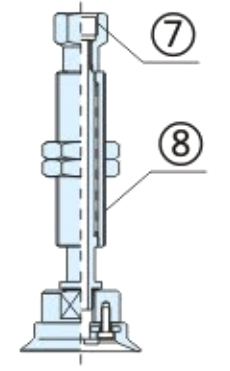

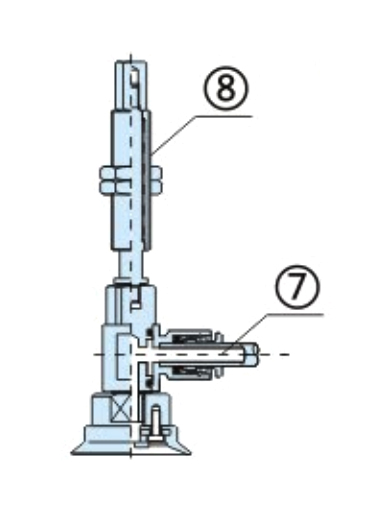

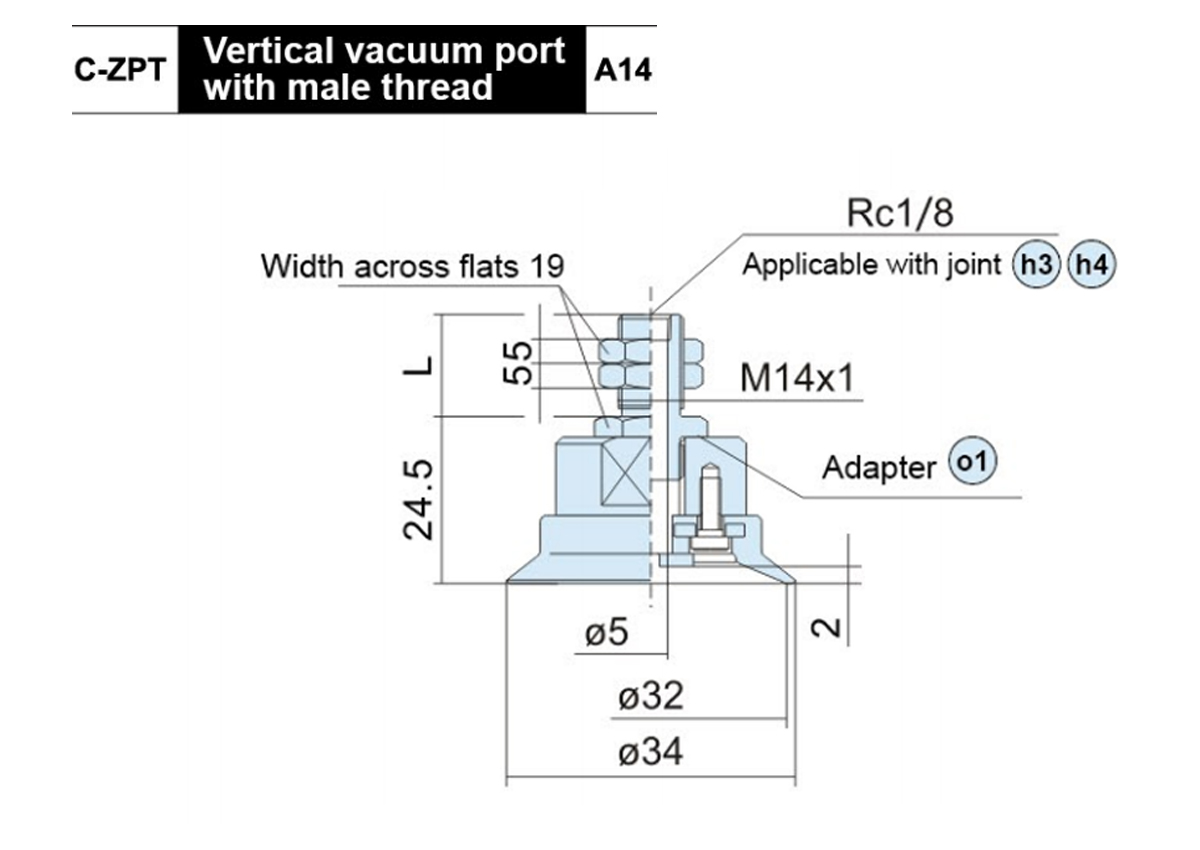

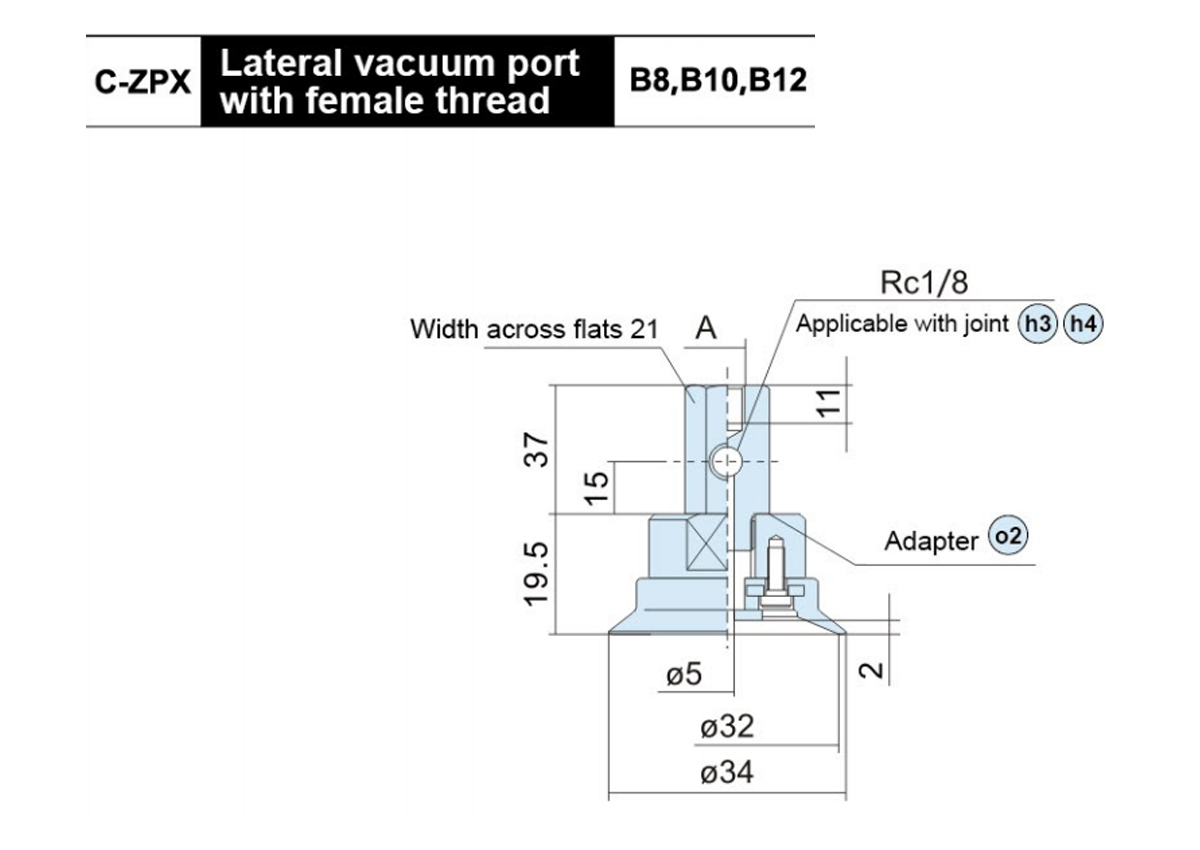

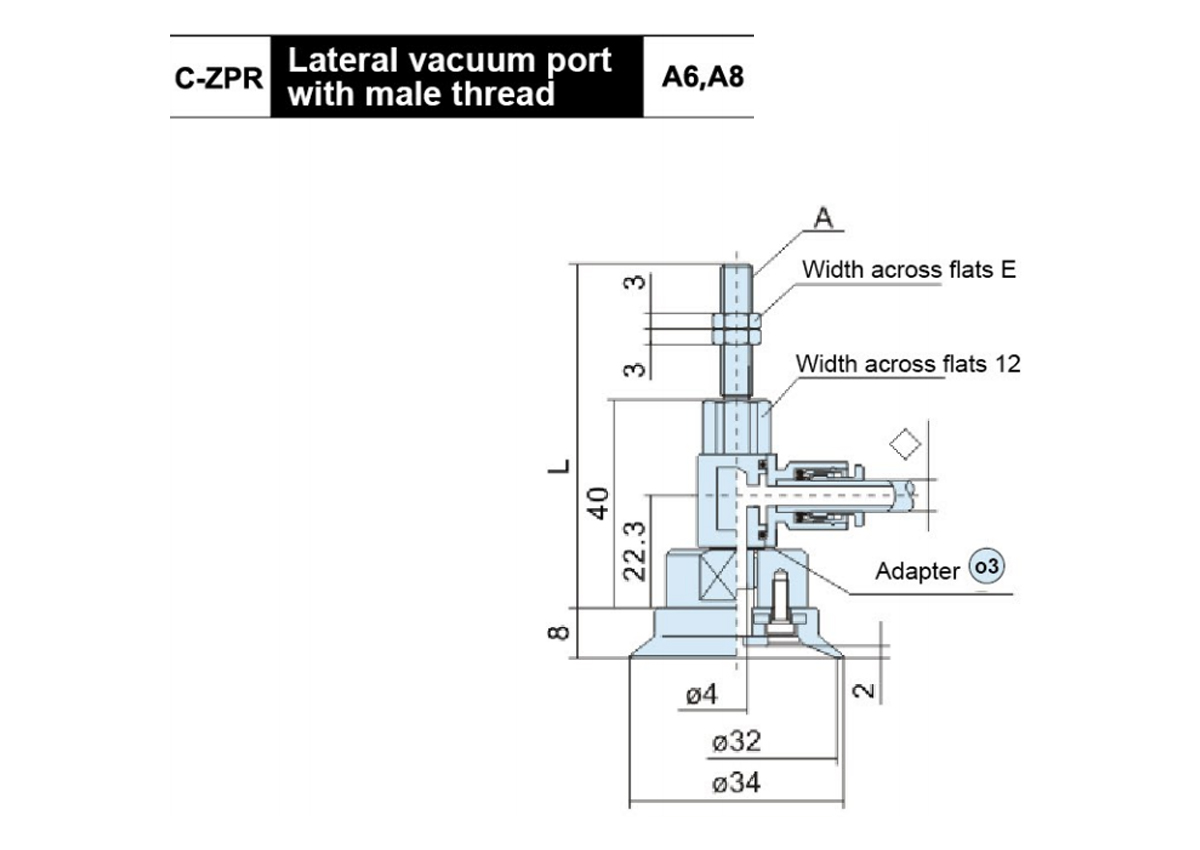

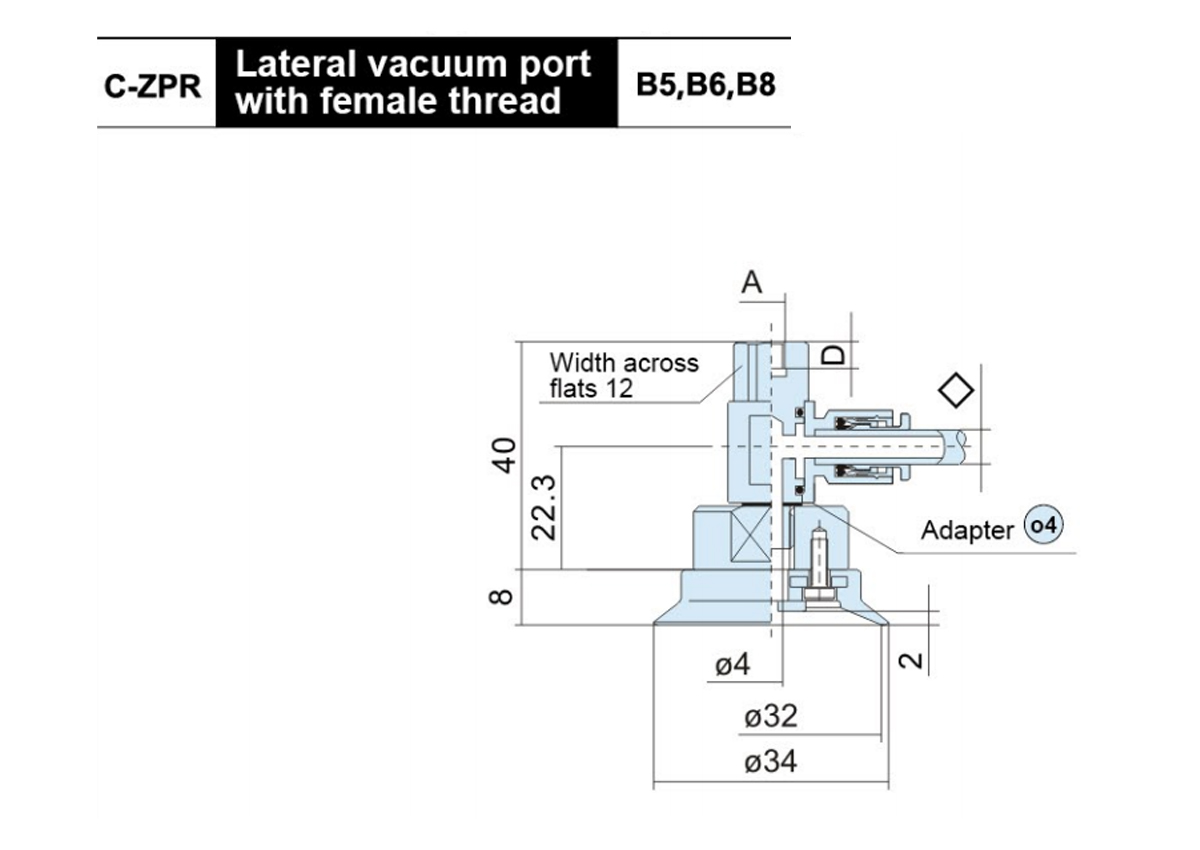

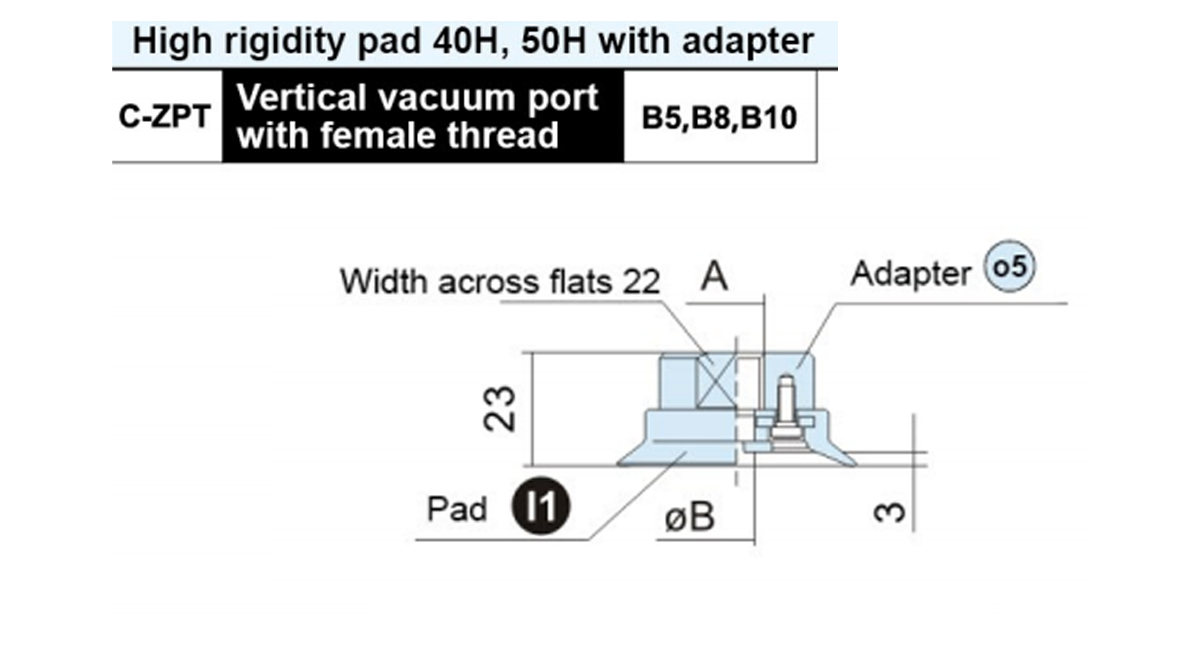

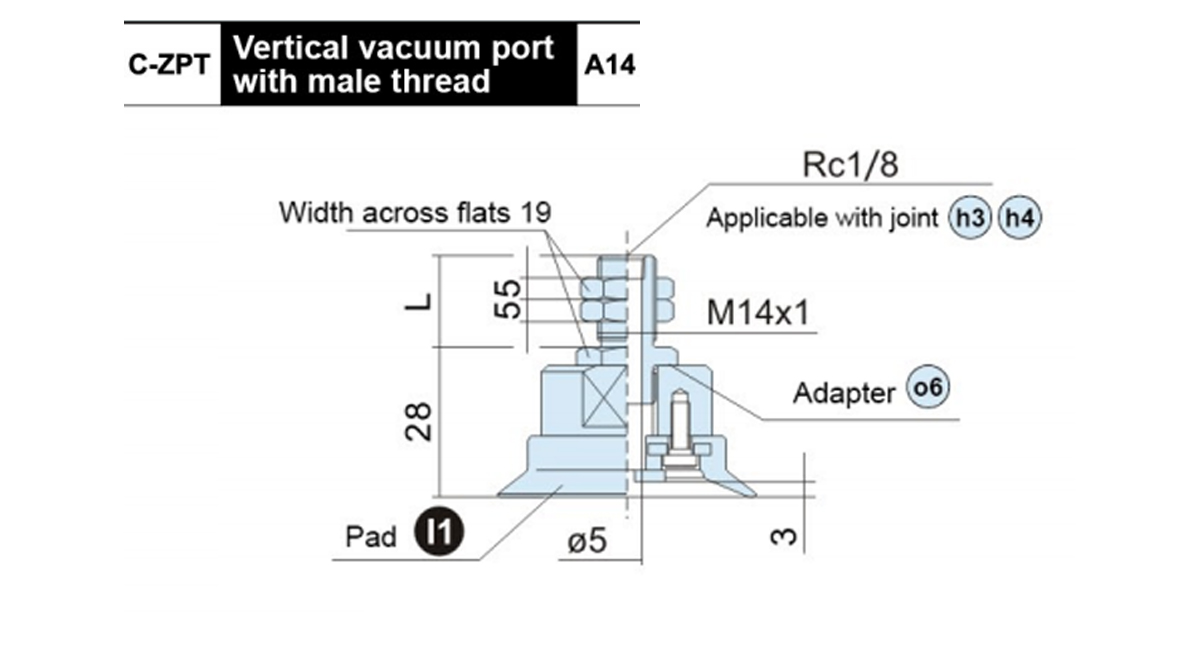

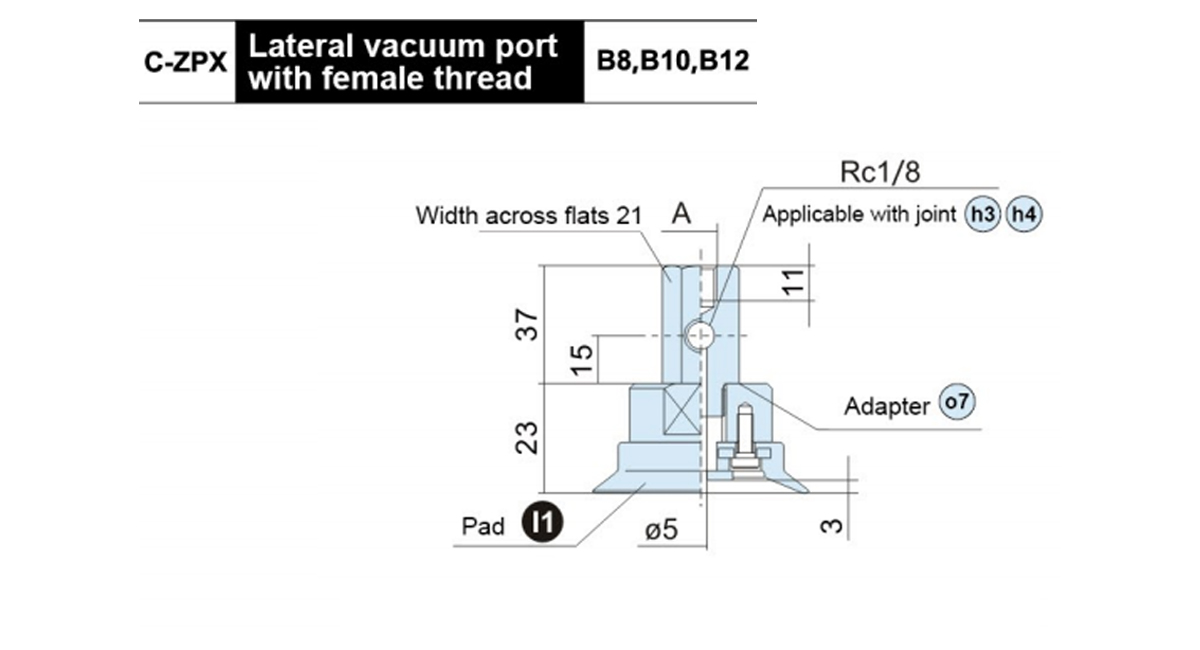

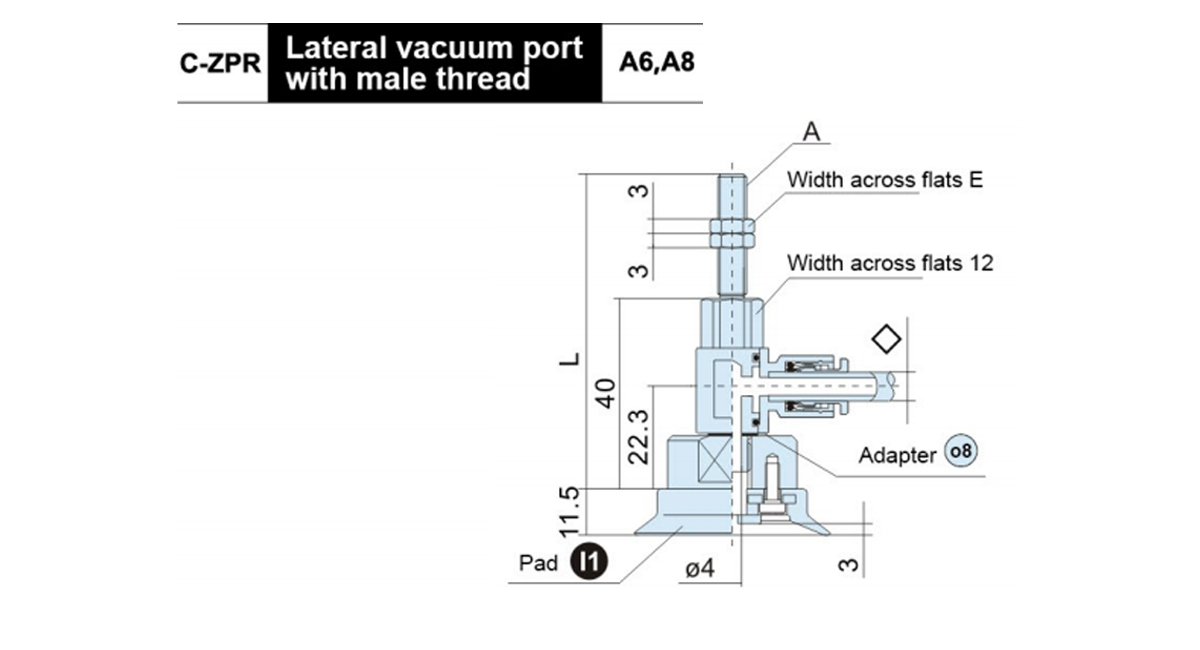

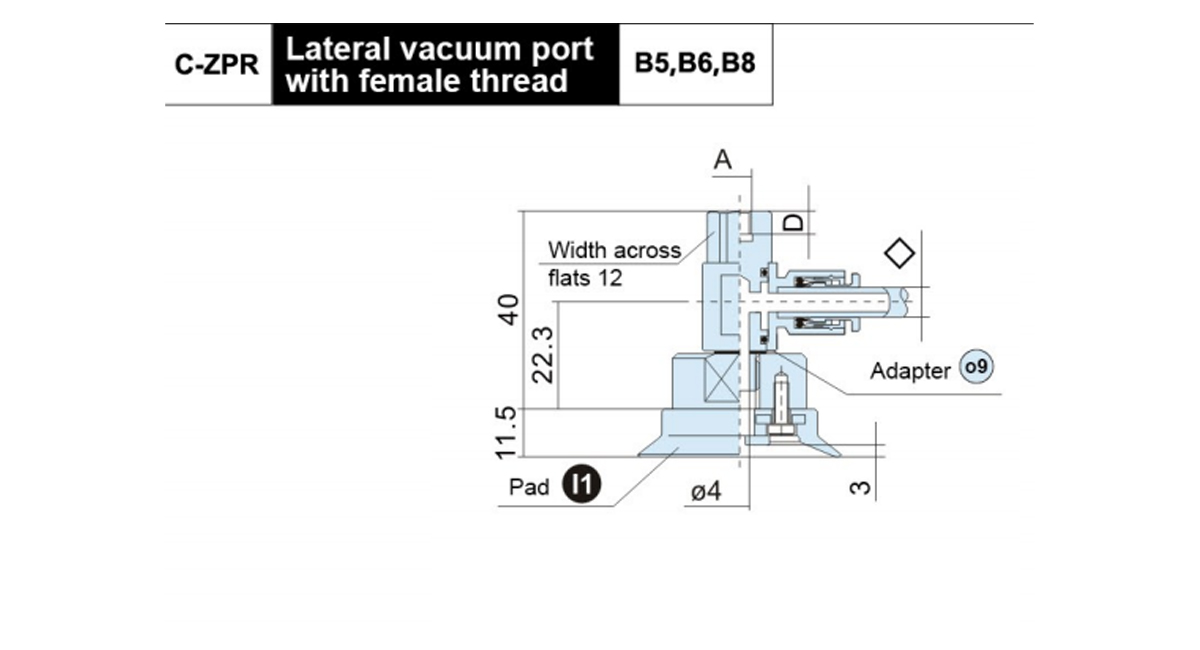

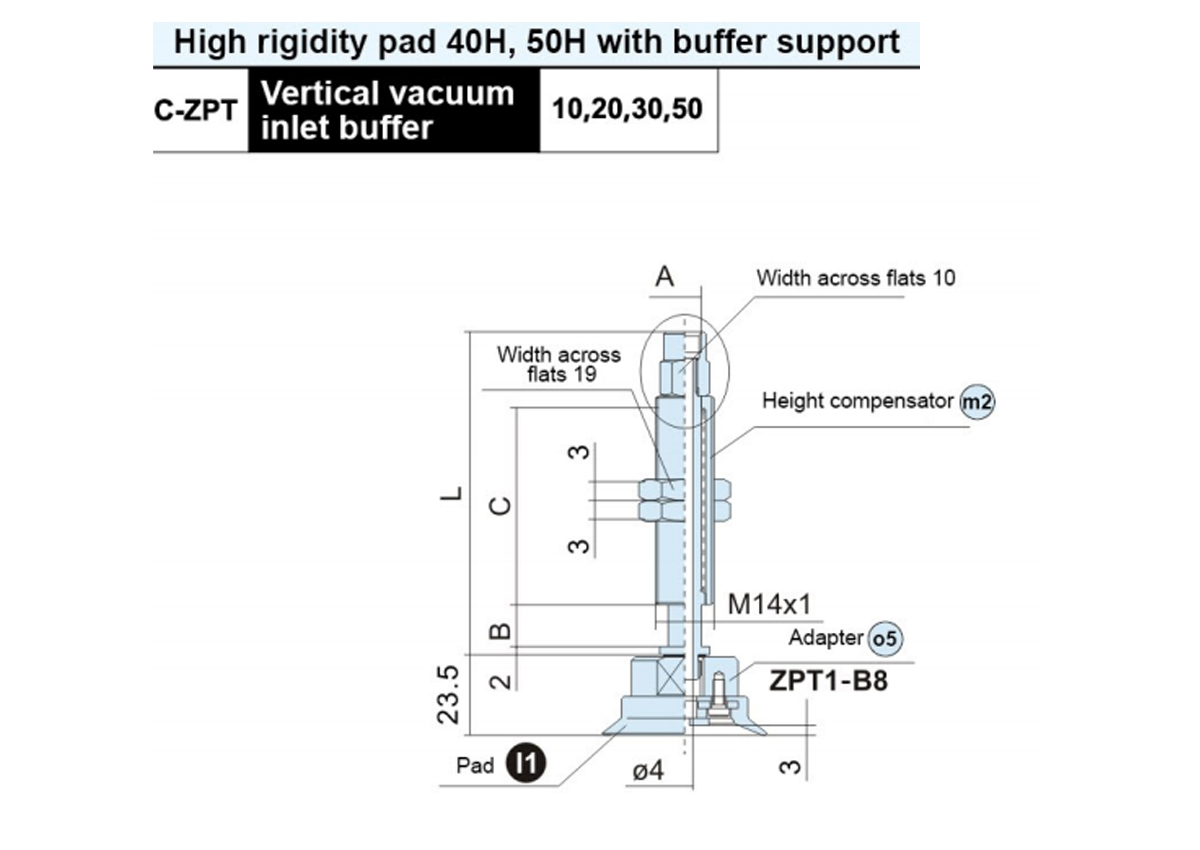

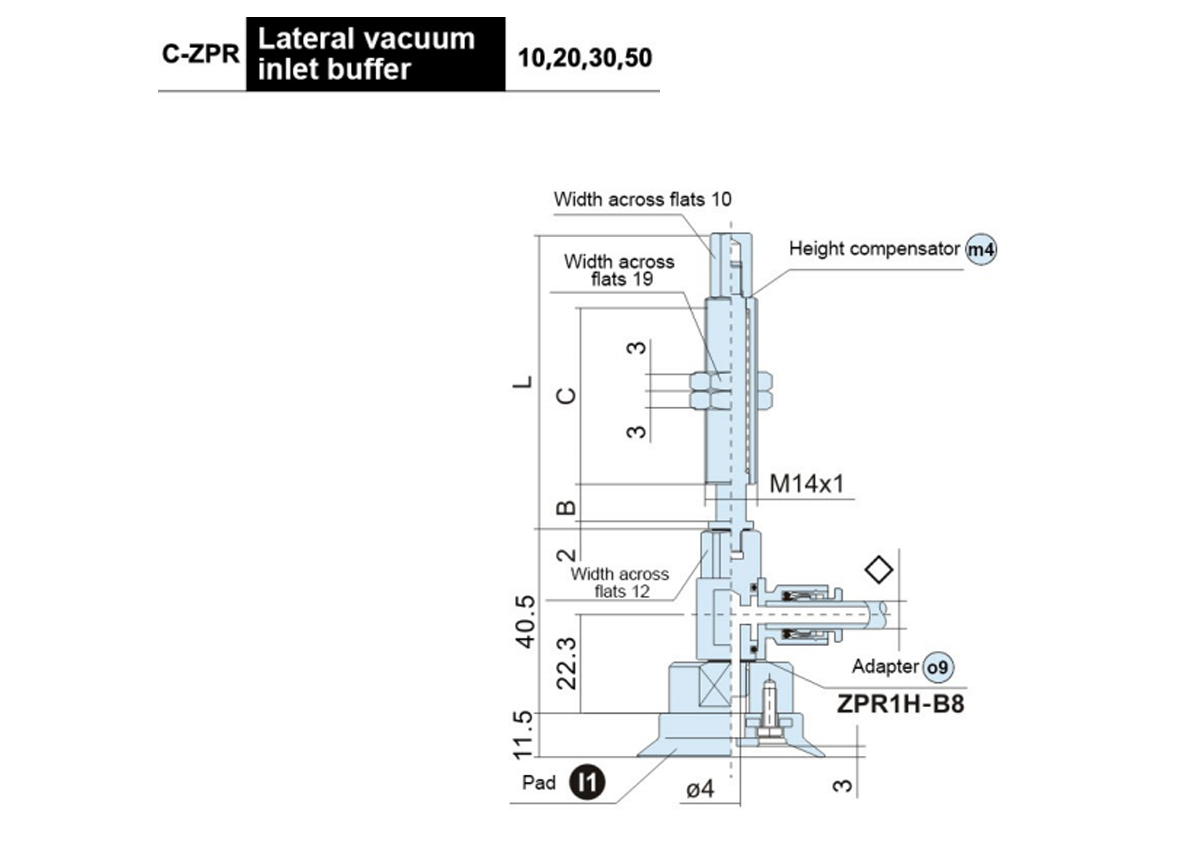

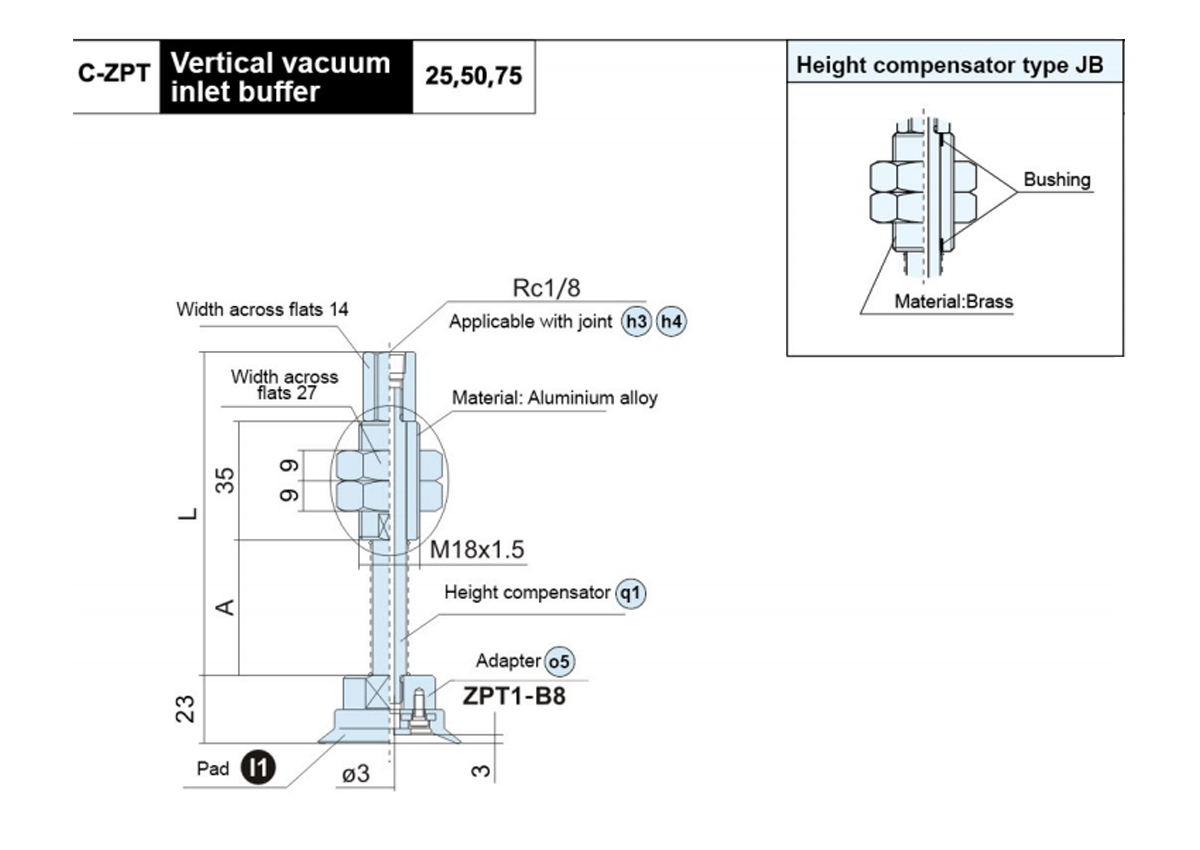

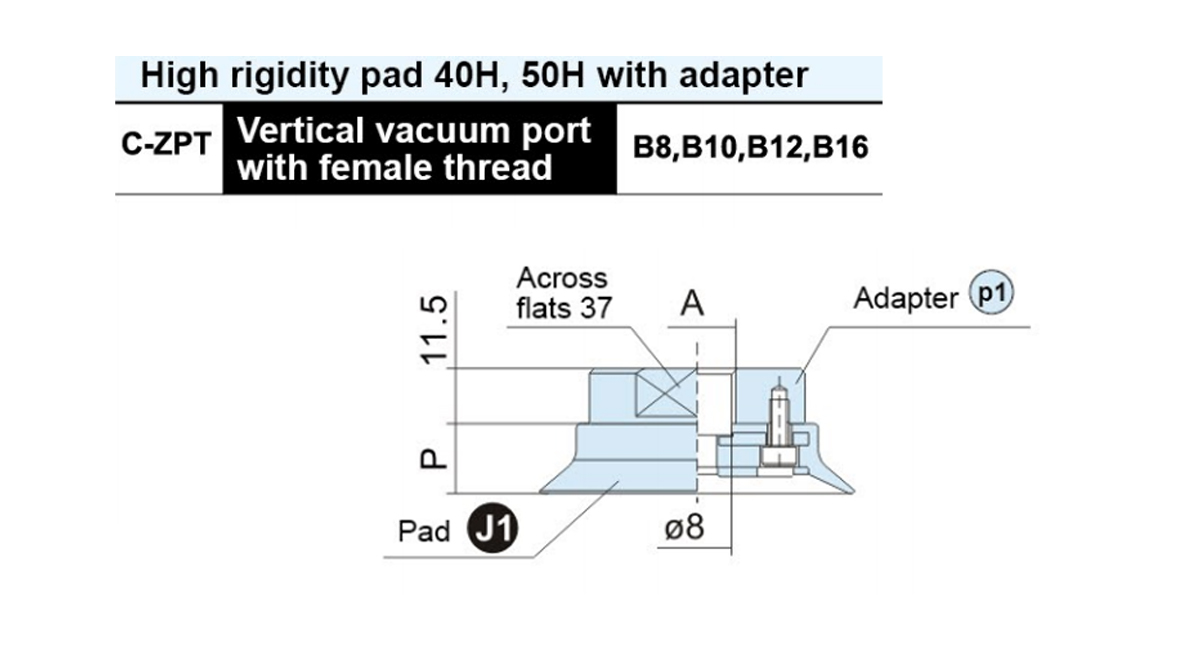

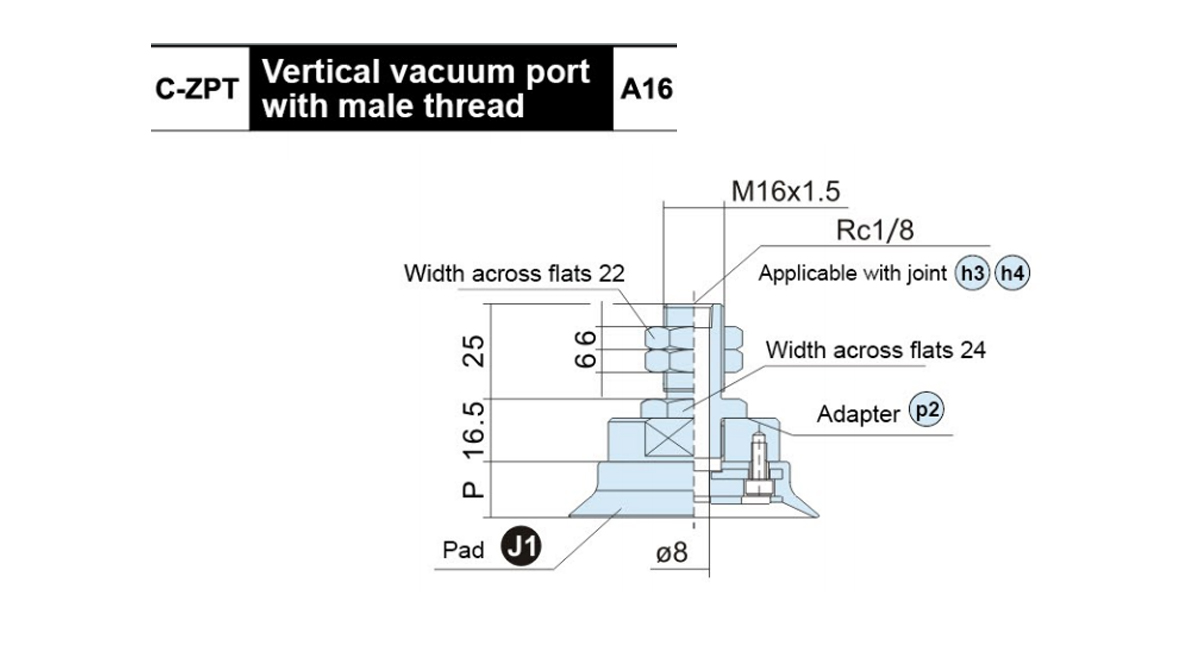

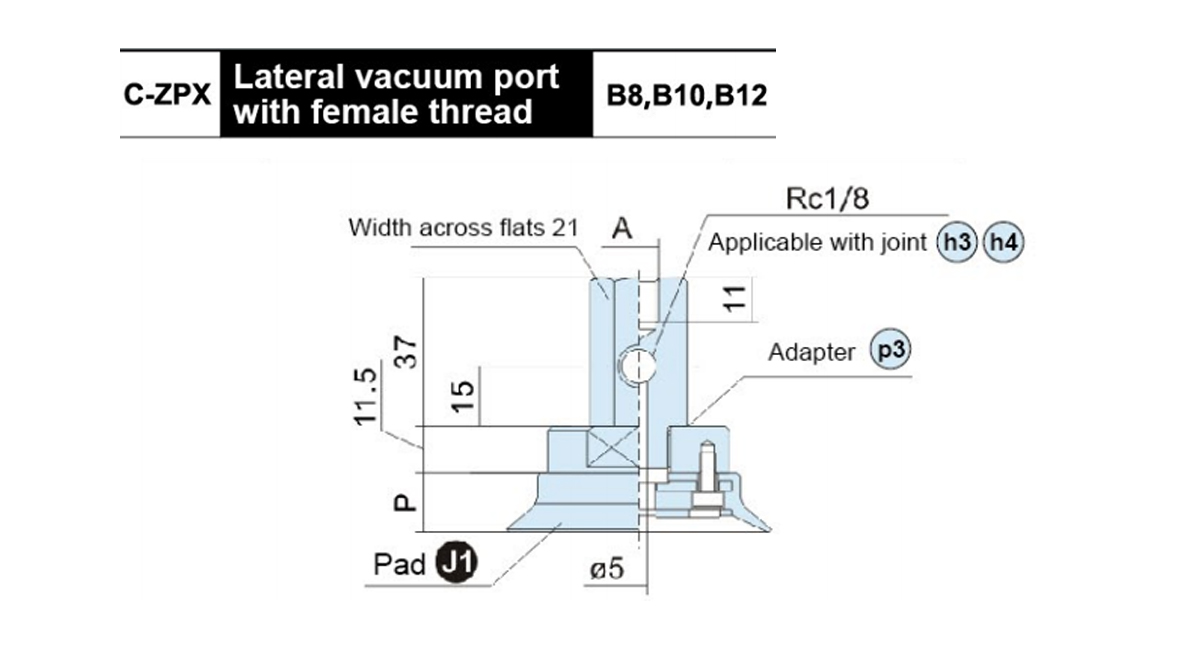

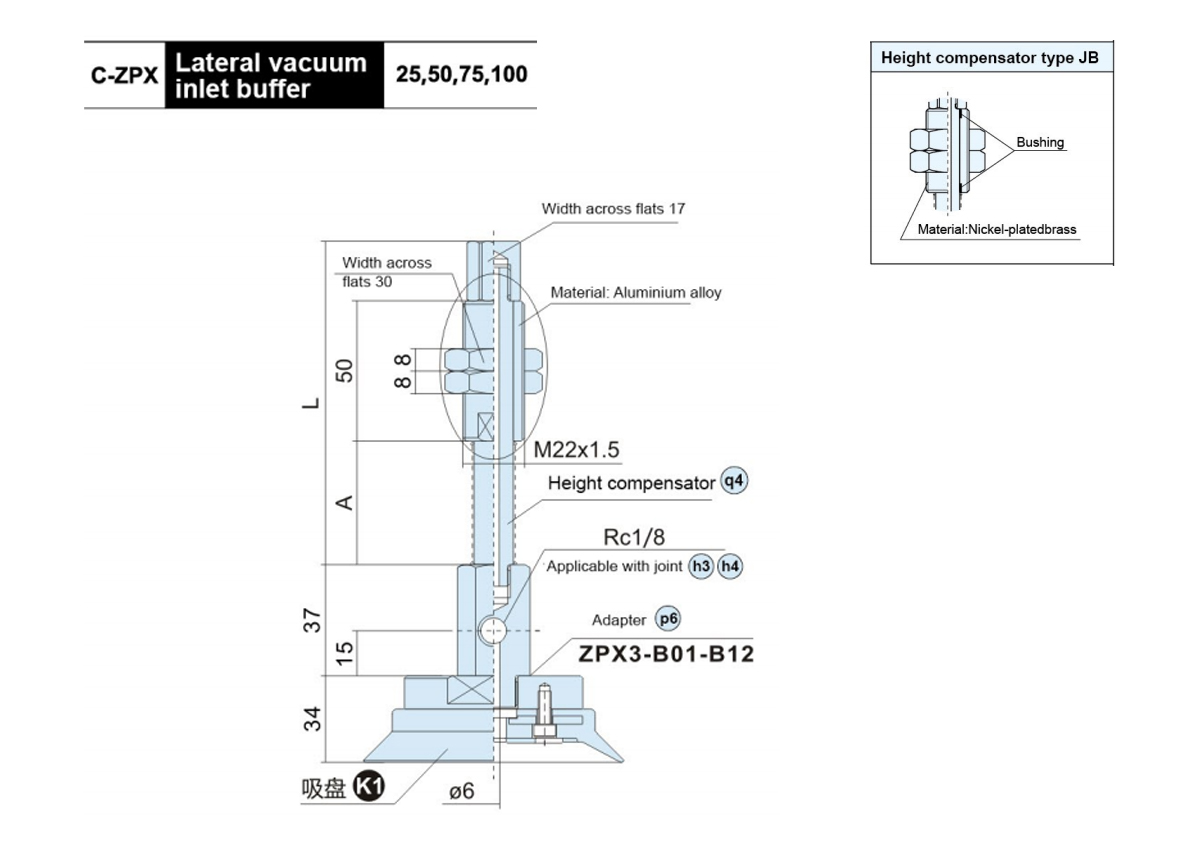

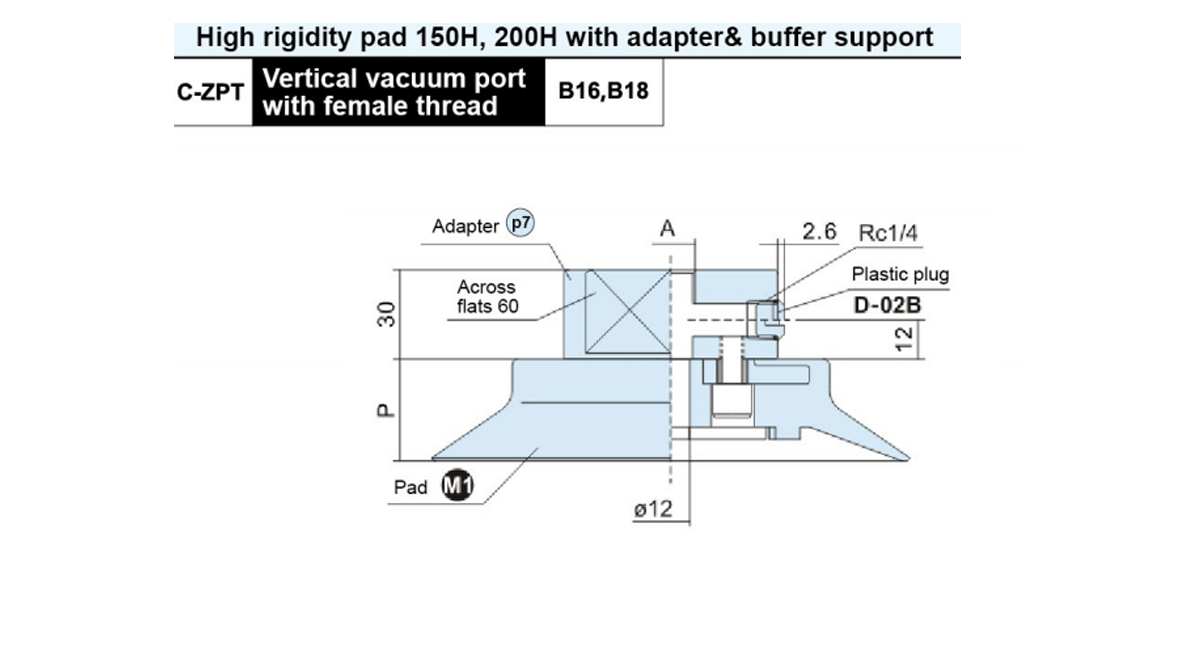

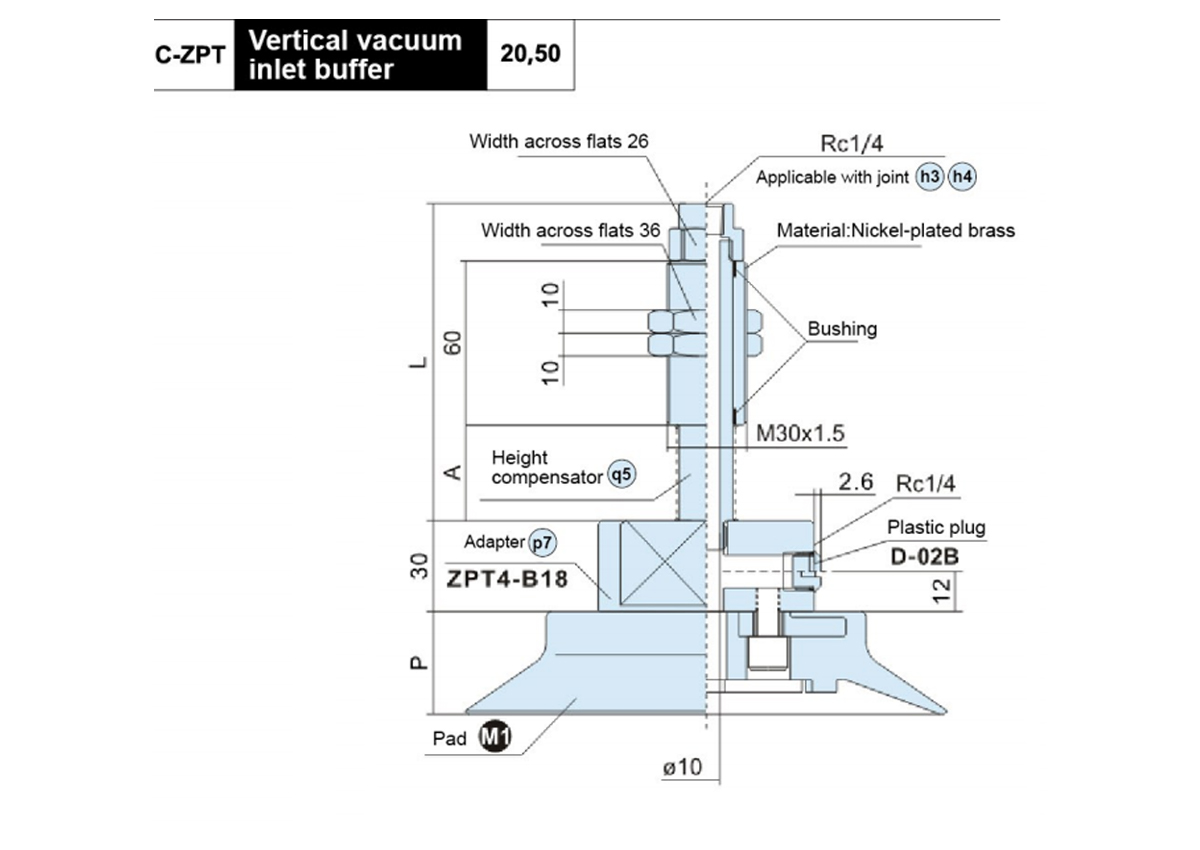

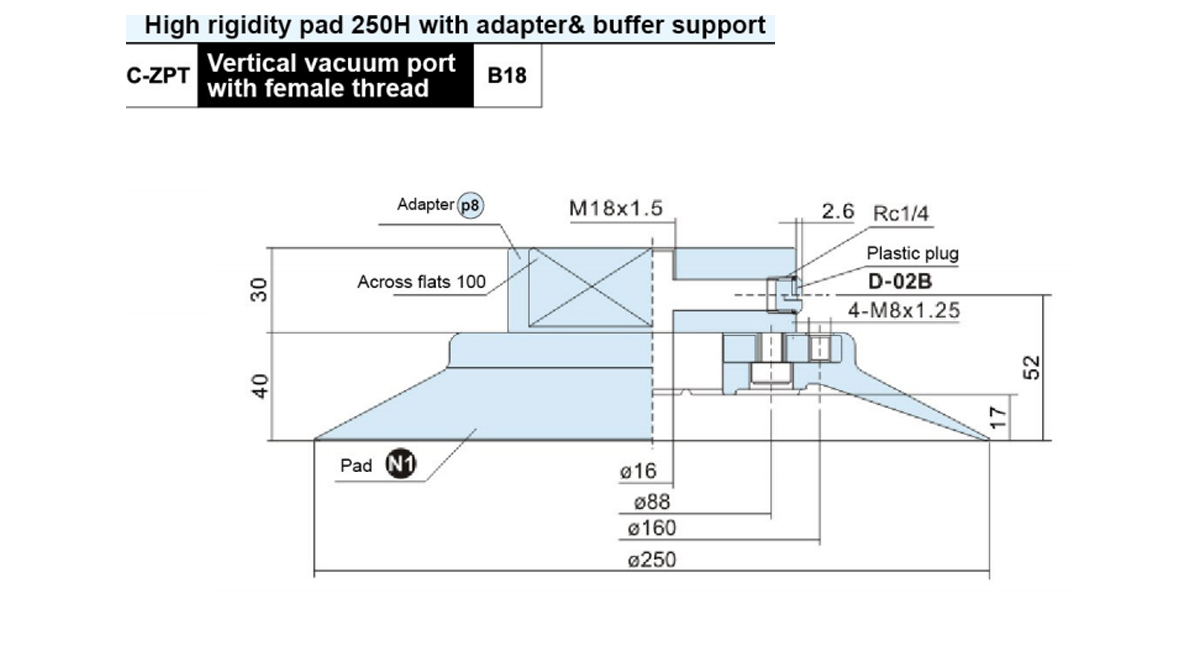

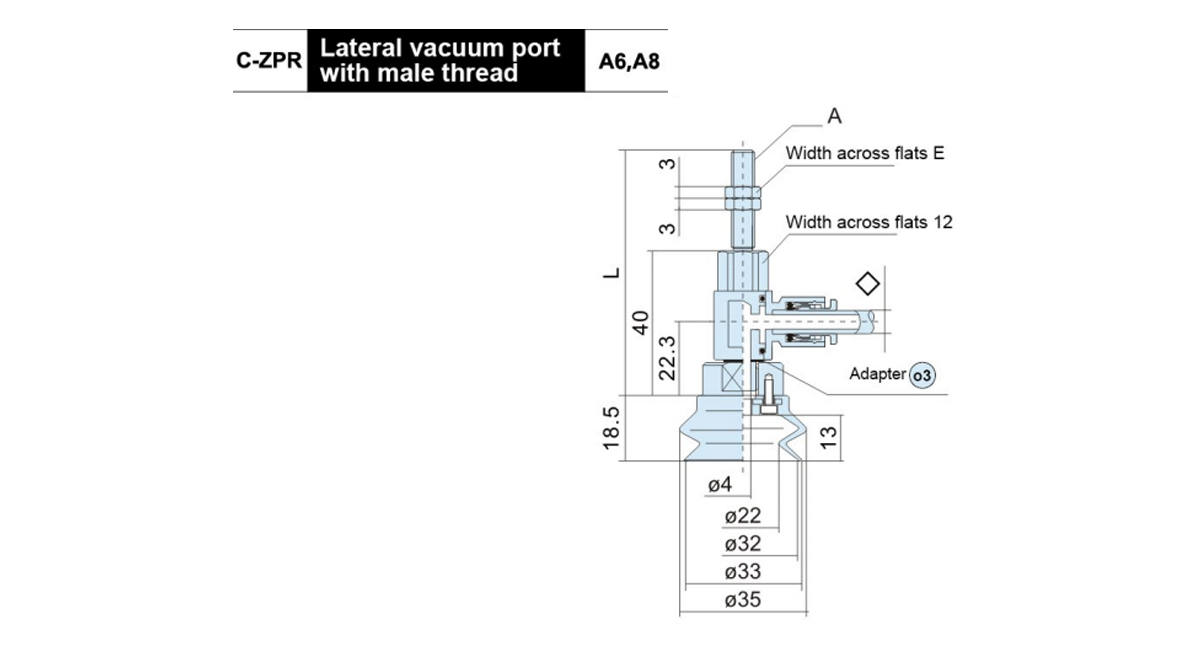

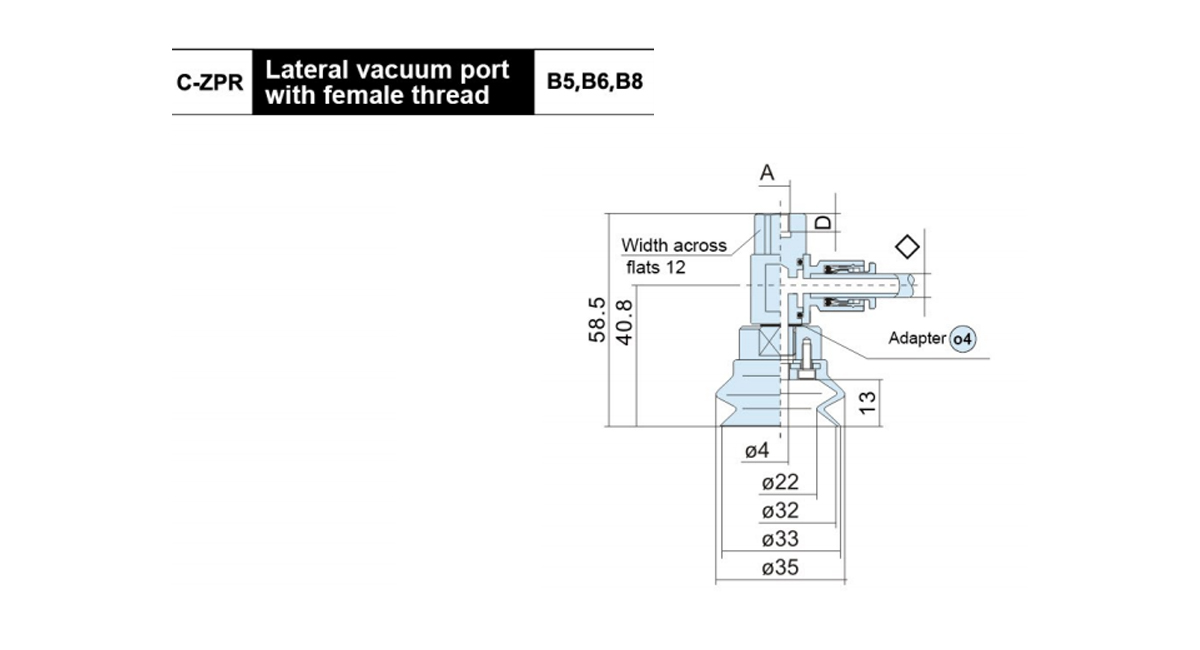

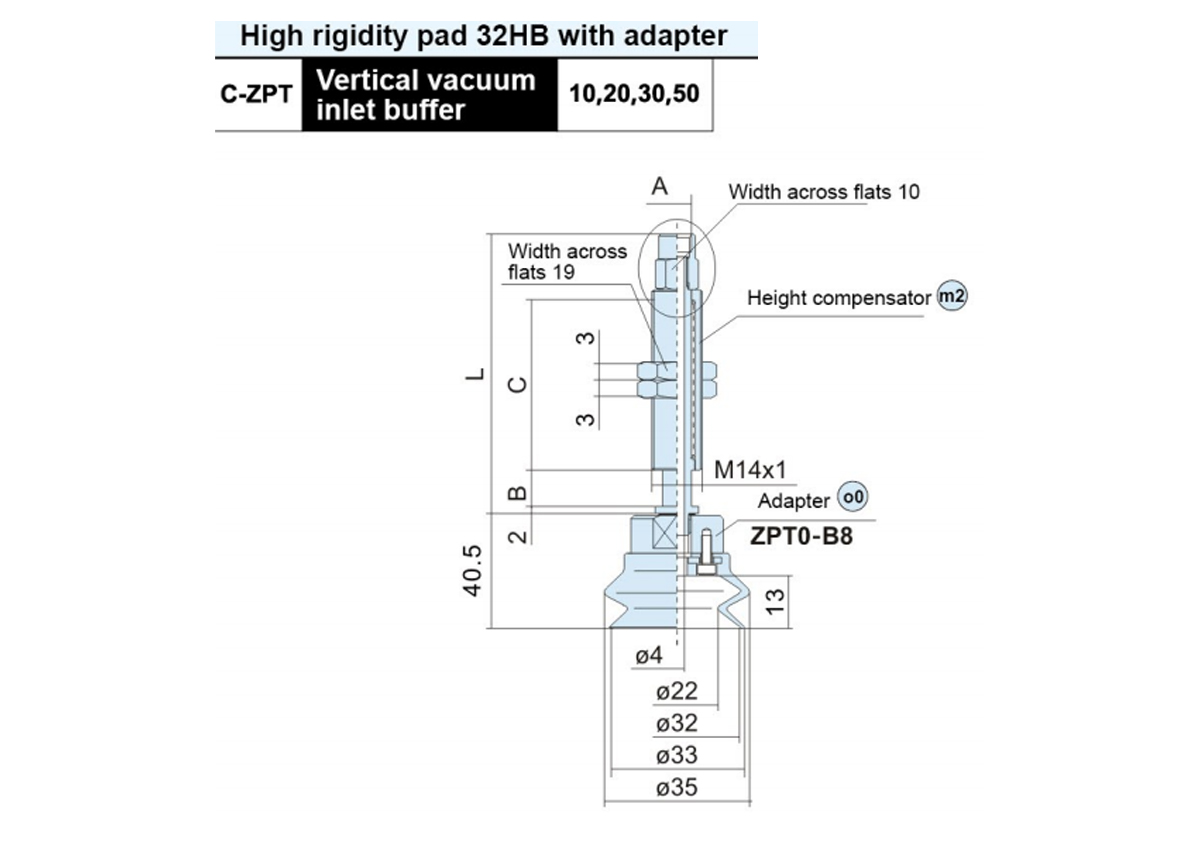

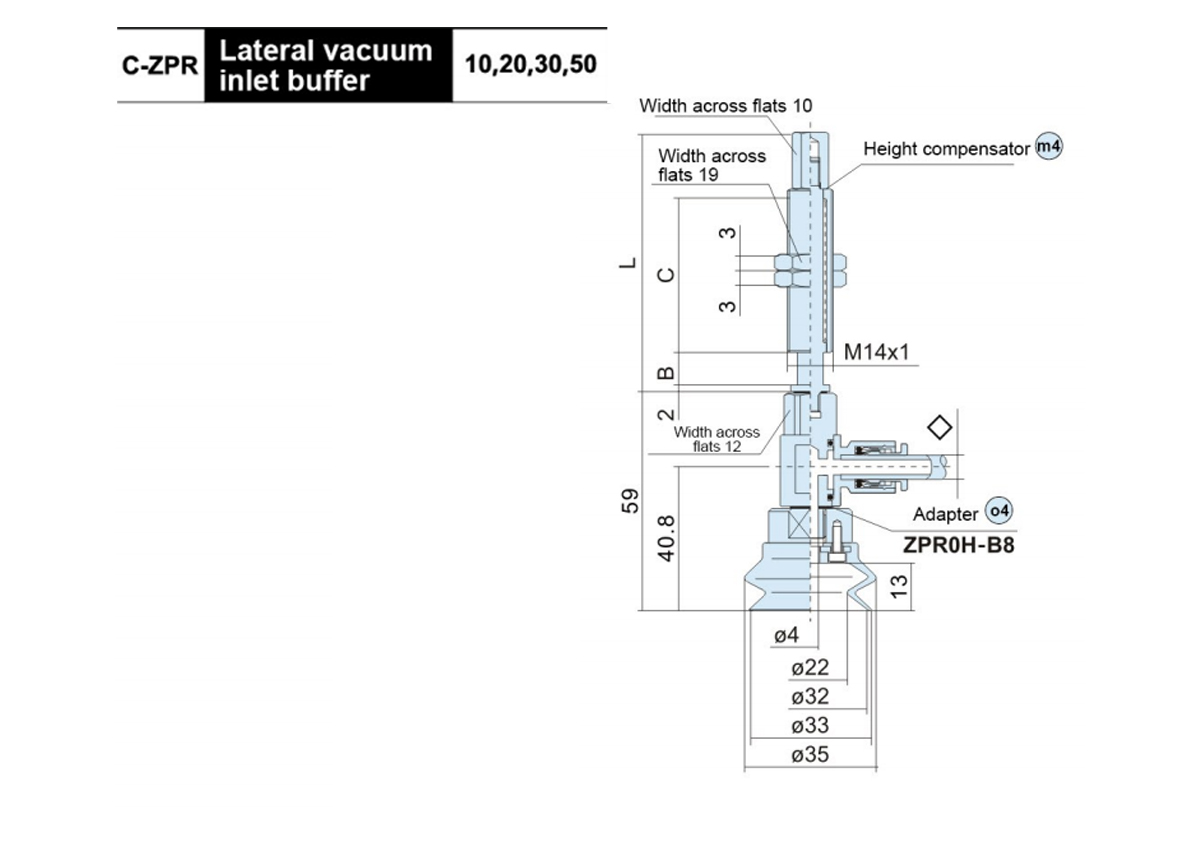

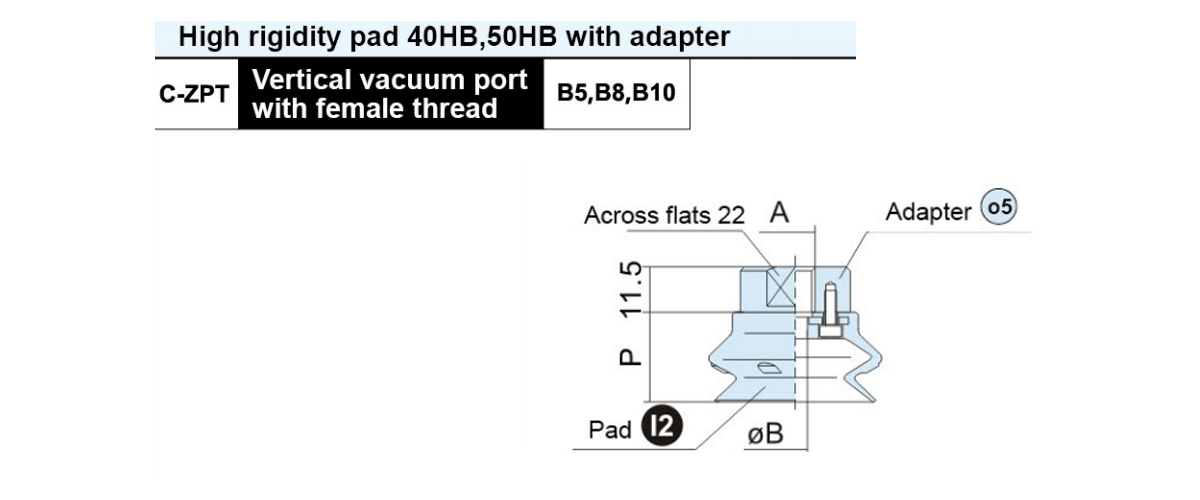

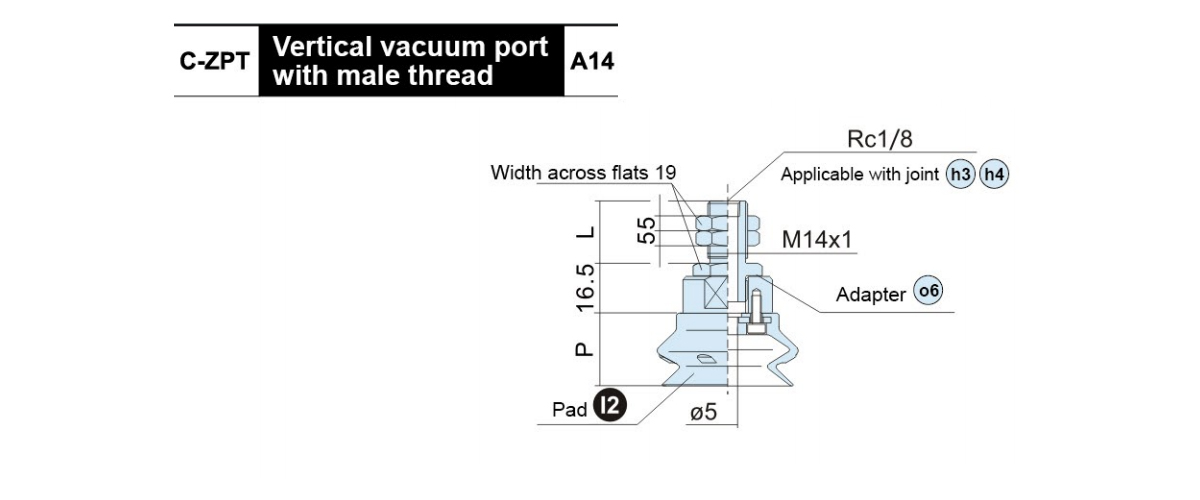

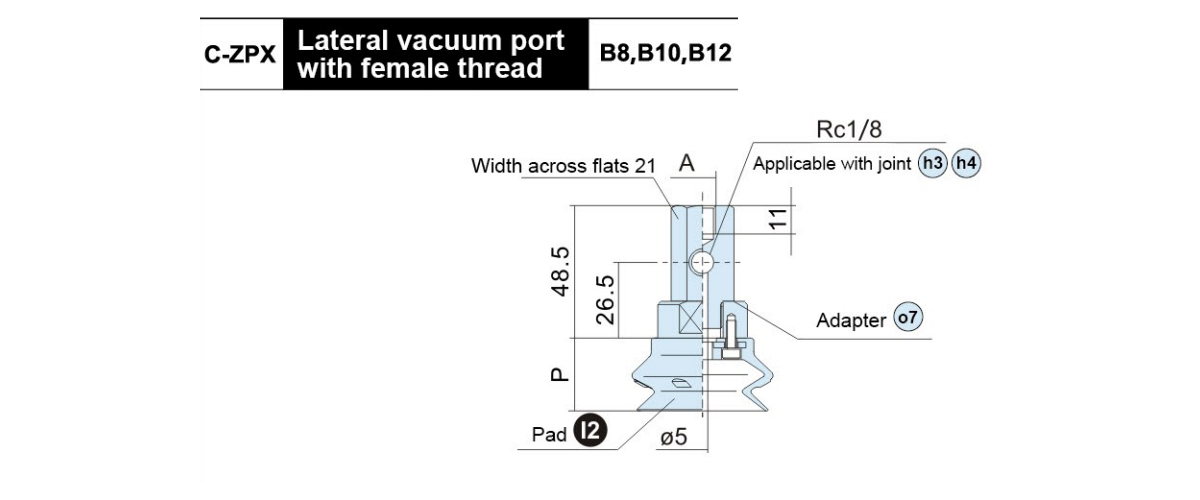

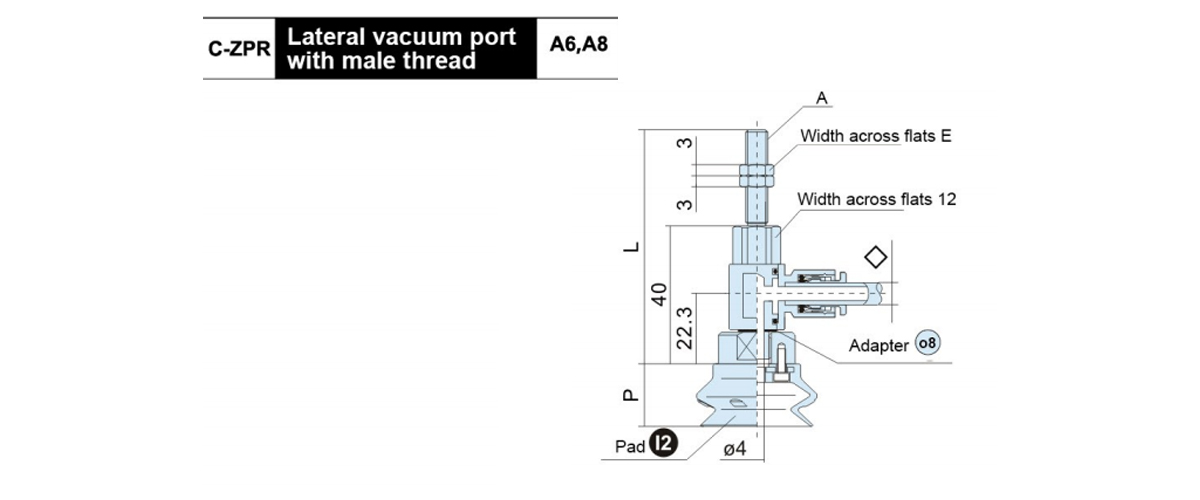

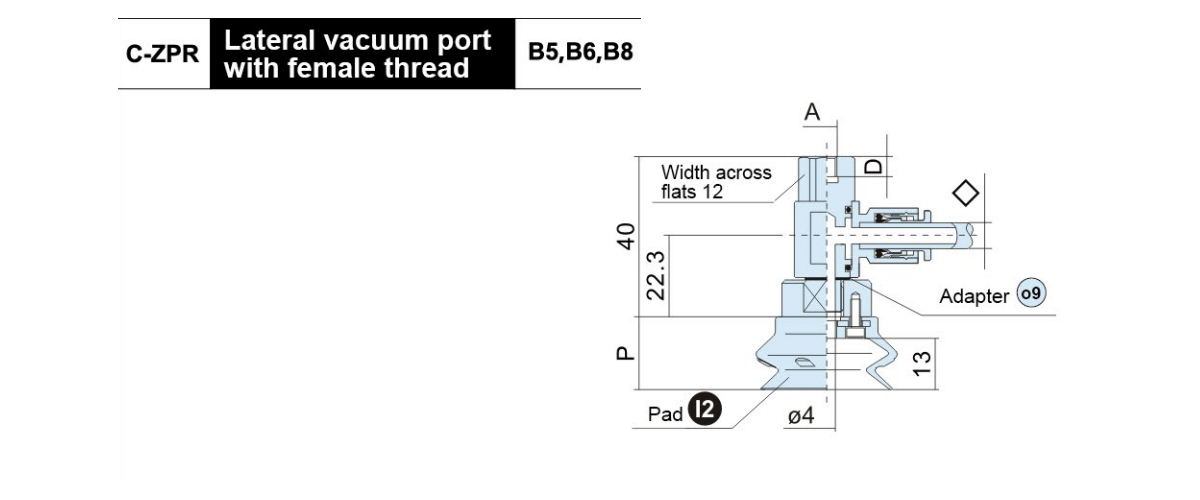

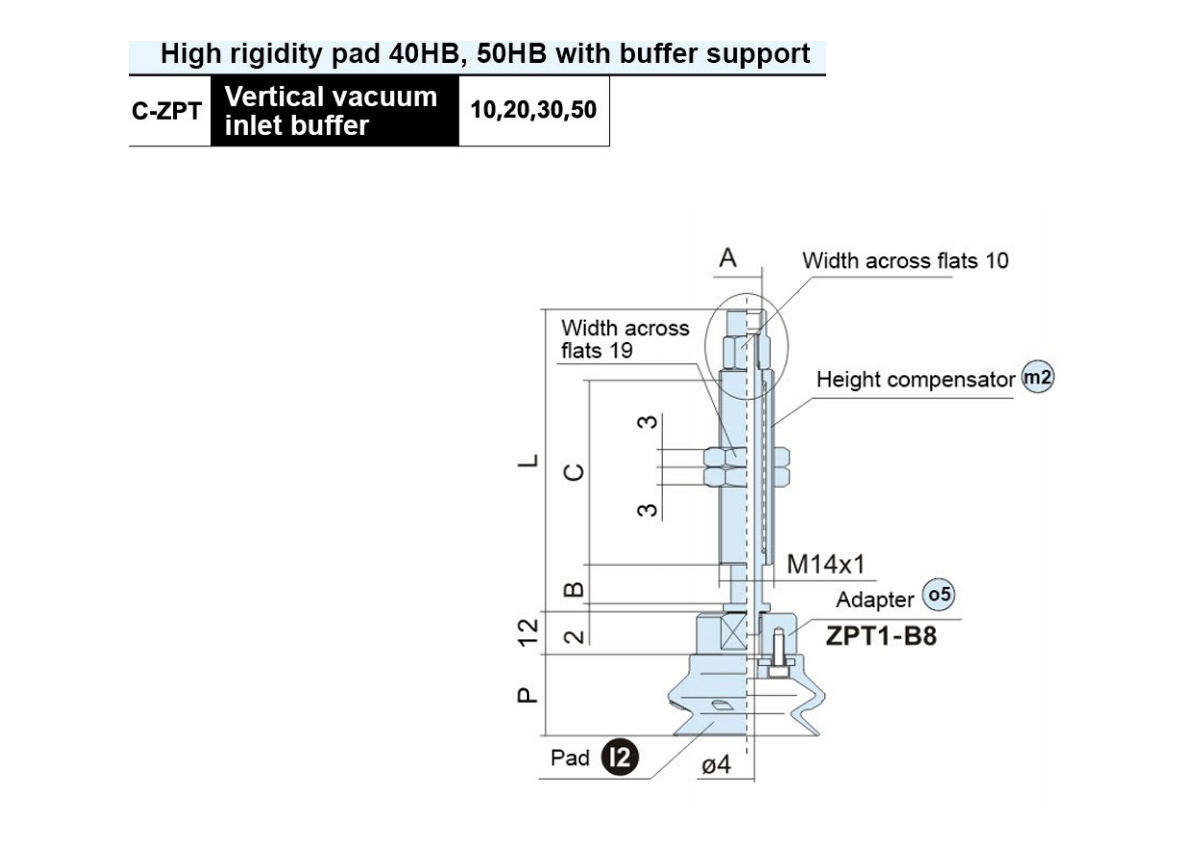

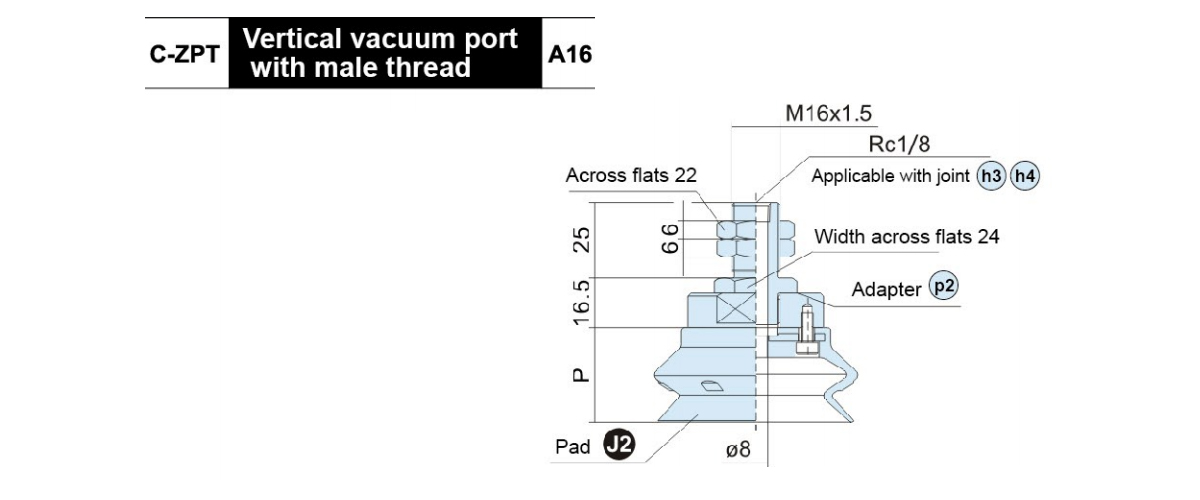

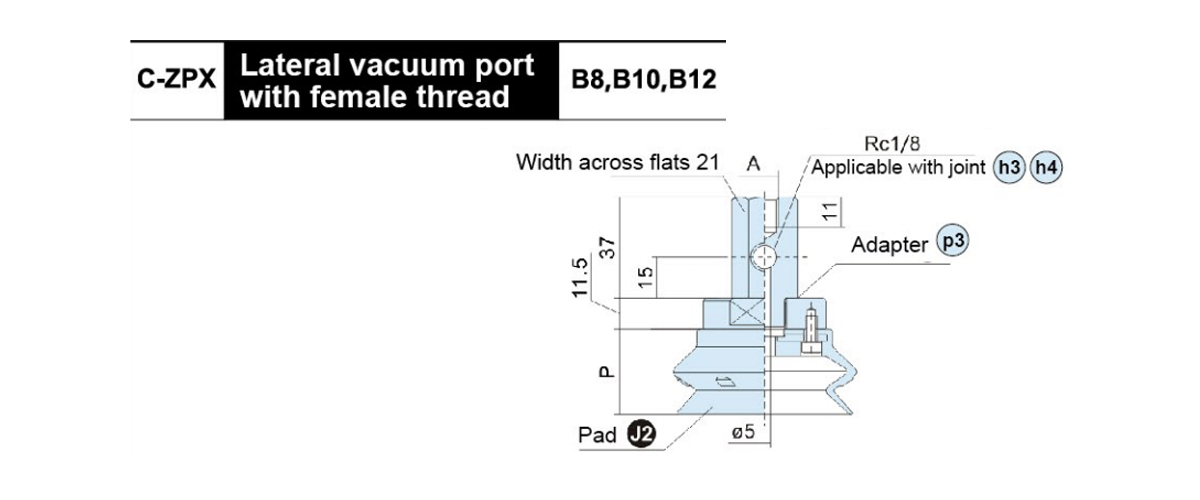

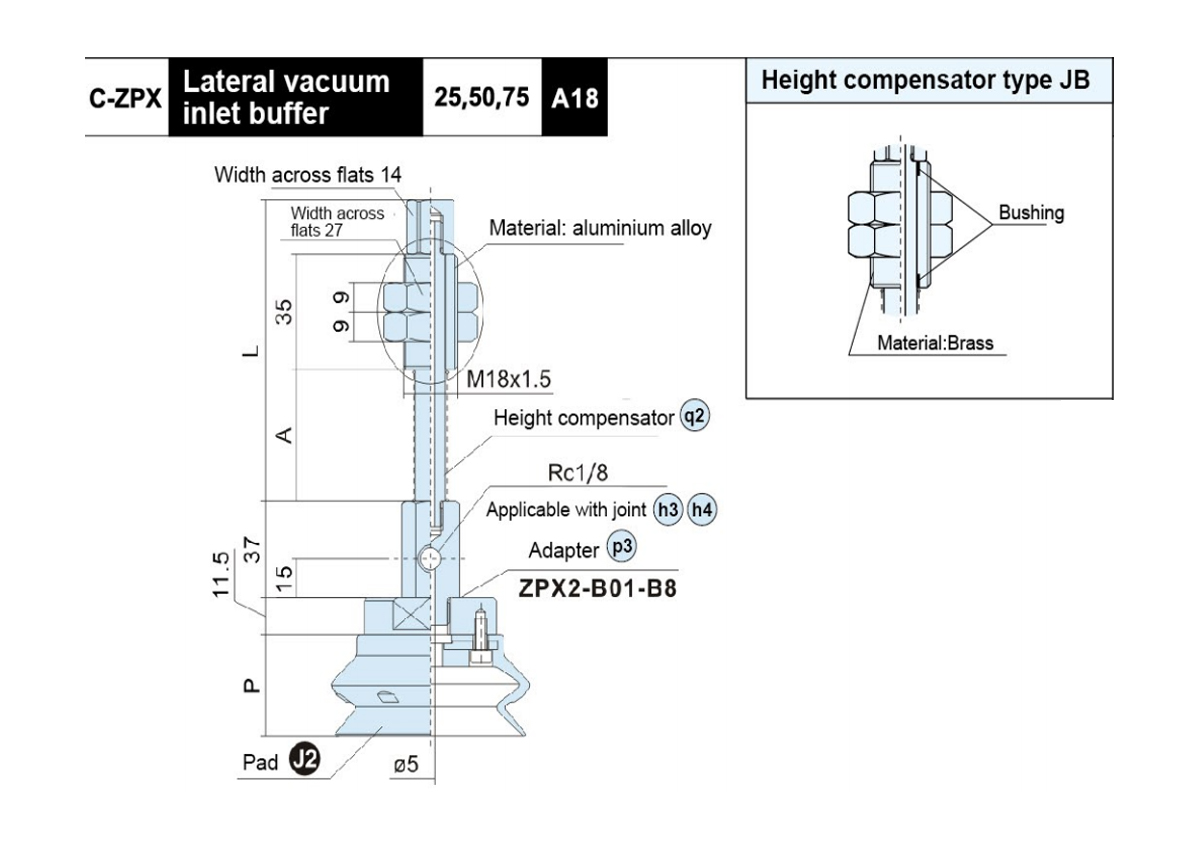

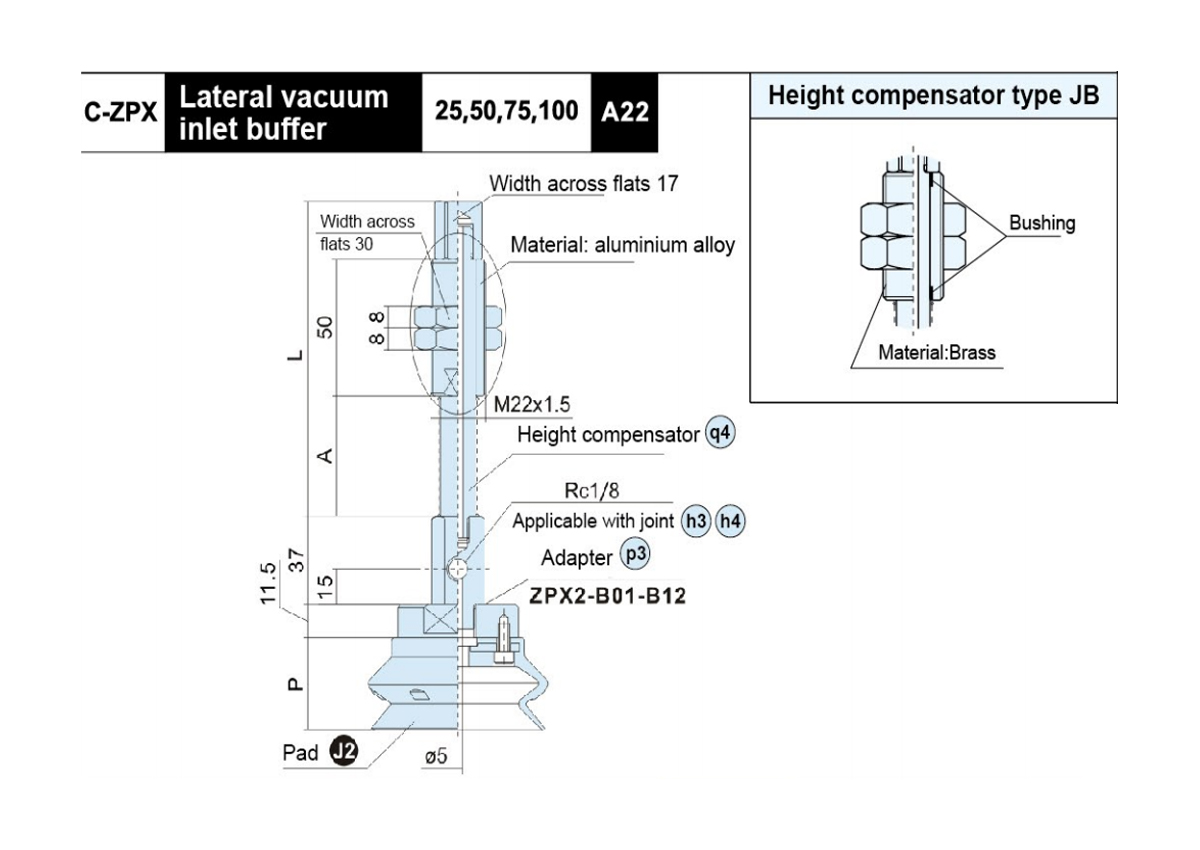

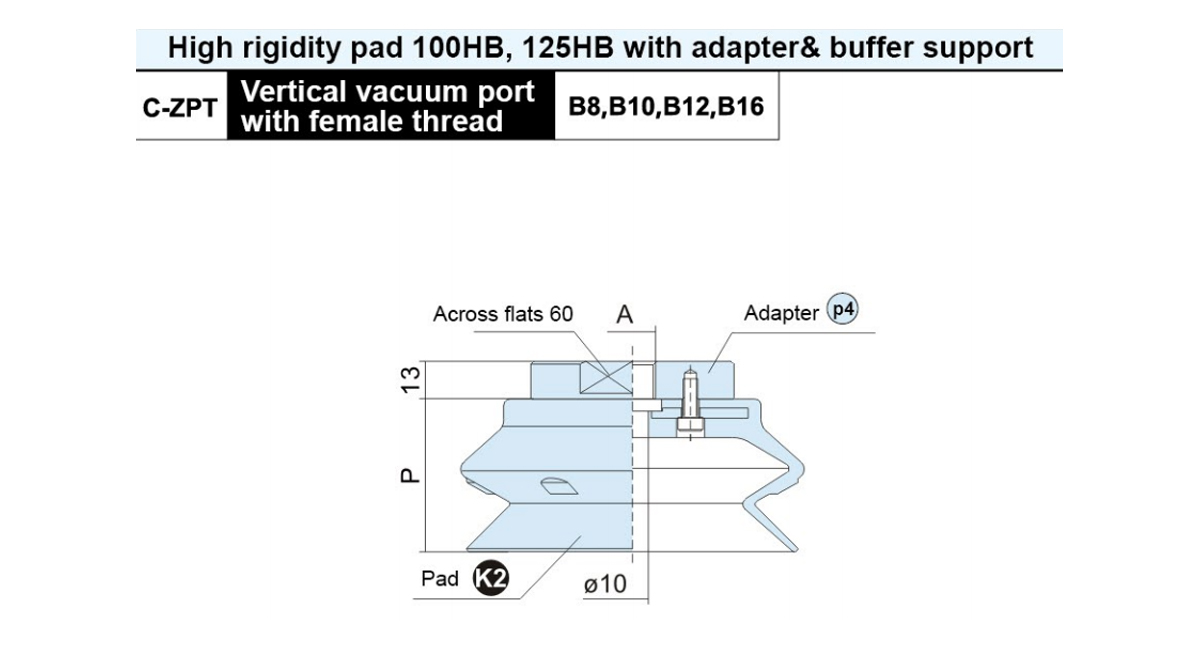

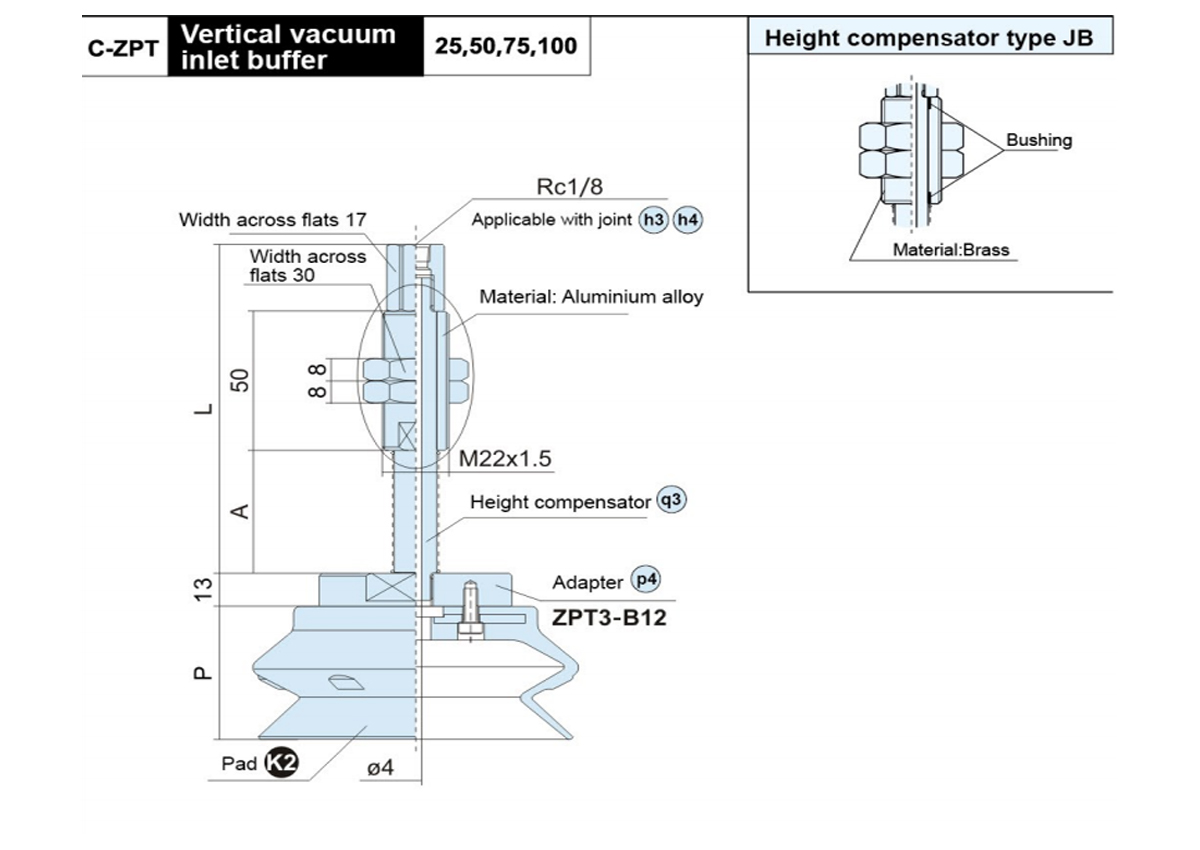

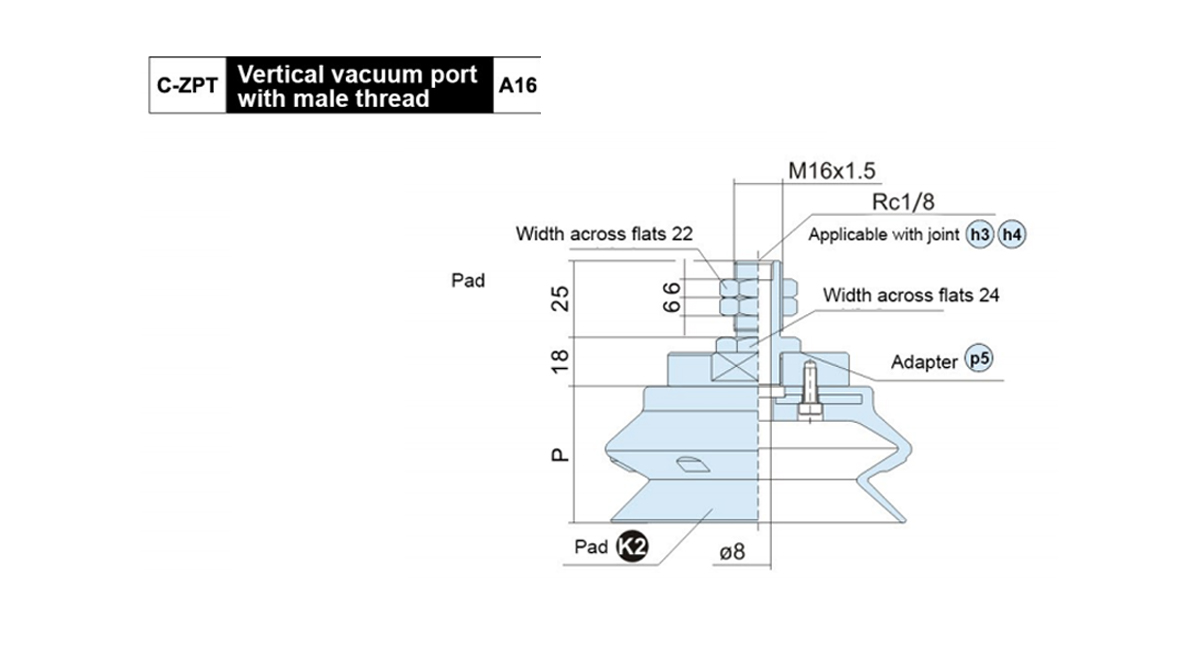

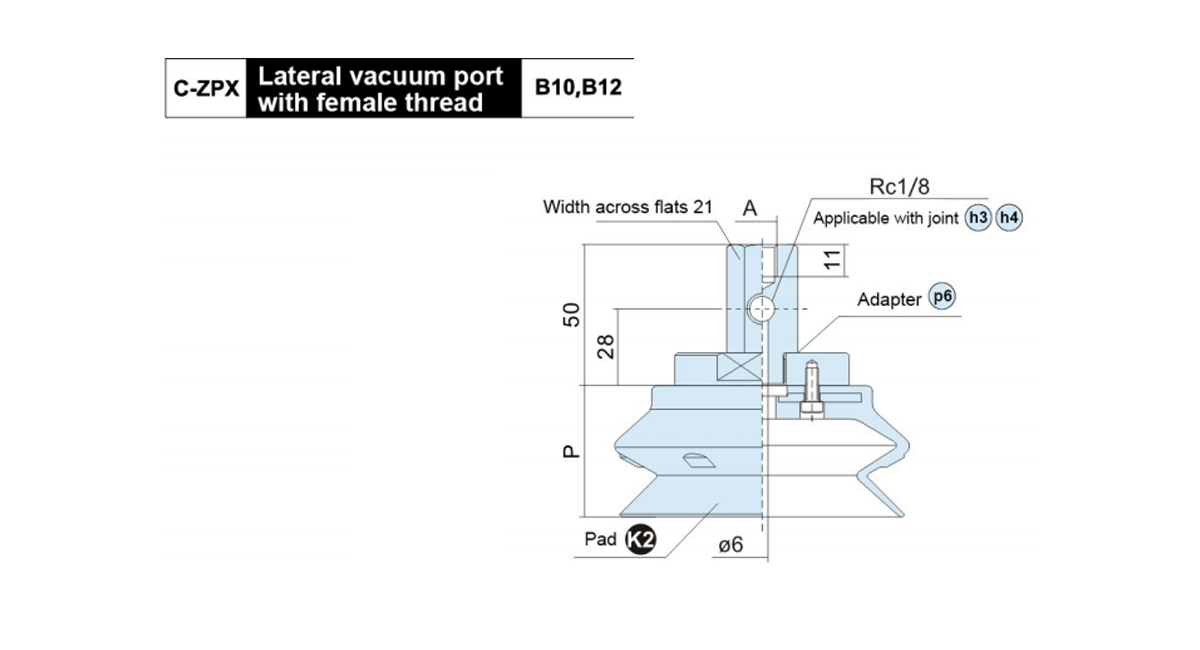

Integrated adapter interface: The standard adapter serves as a dedicated transfer hub between the suction cup body and the downstream vacuum system (such as generator, distributor) or actuator (such as the end of the robot arm), ensuring efficient gas path connection and physical compatibility.

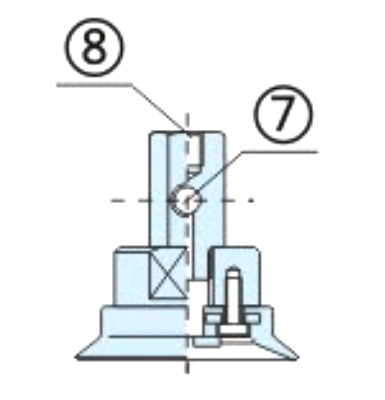

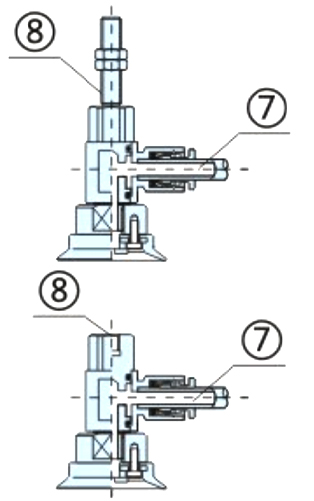

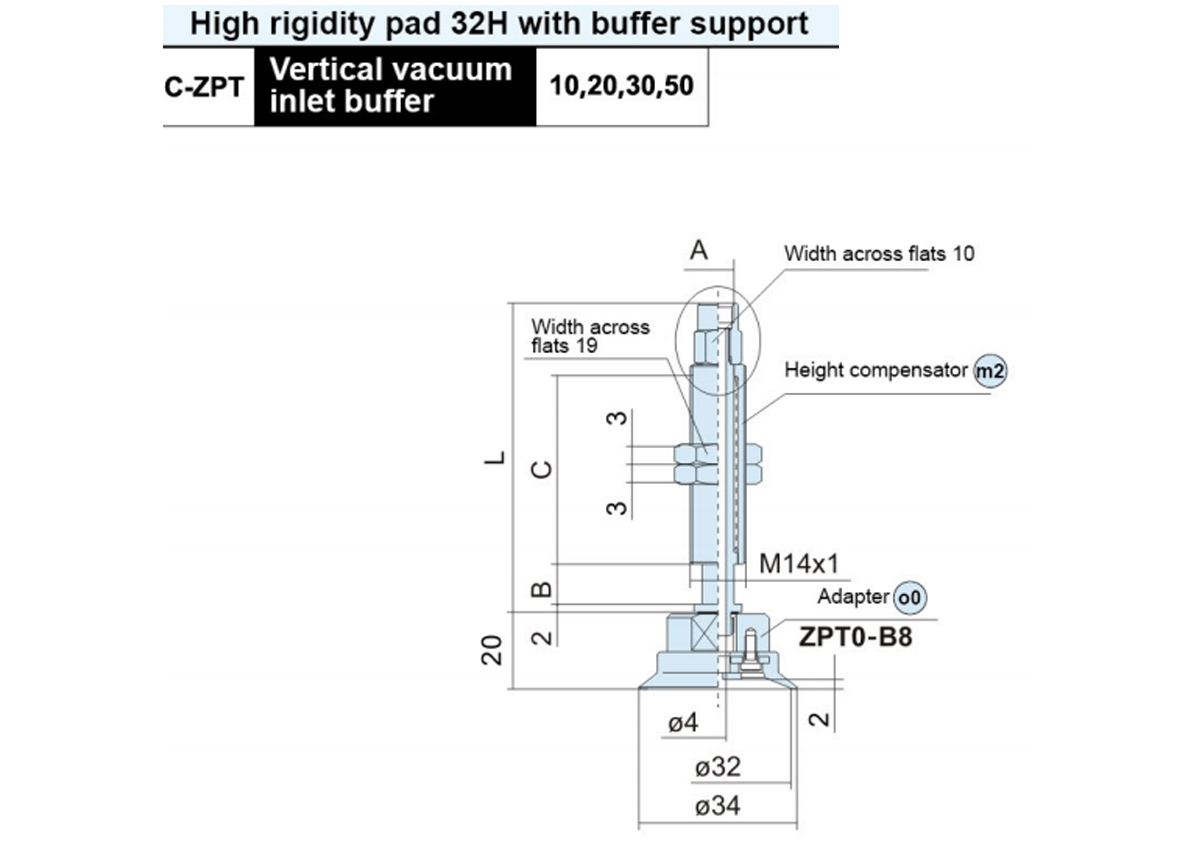

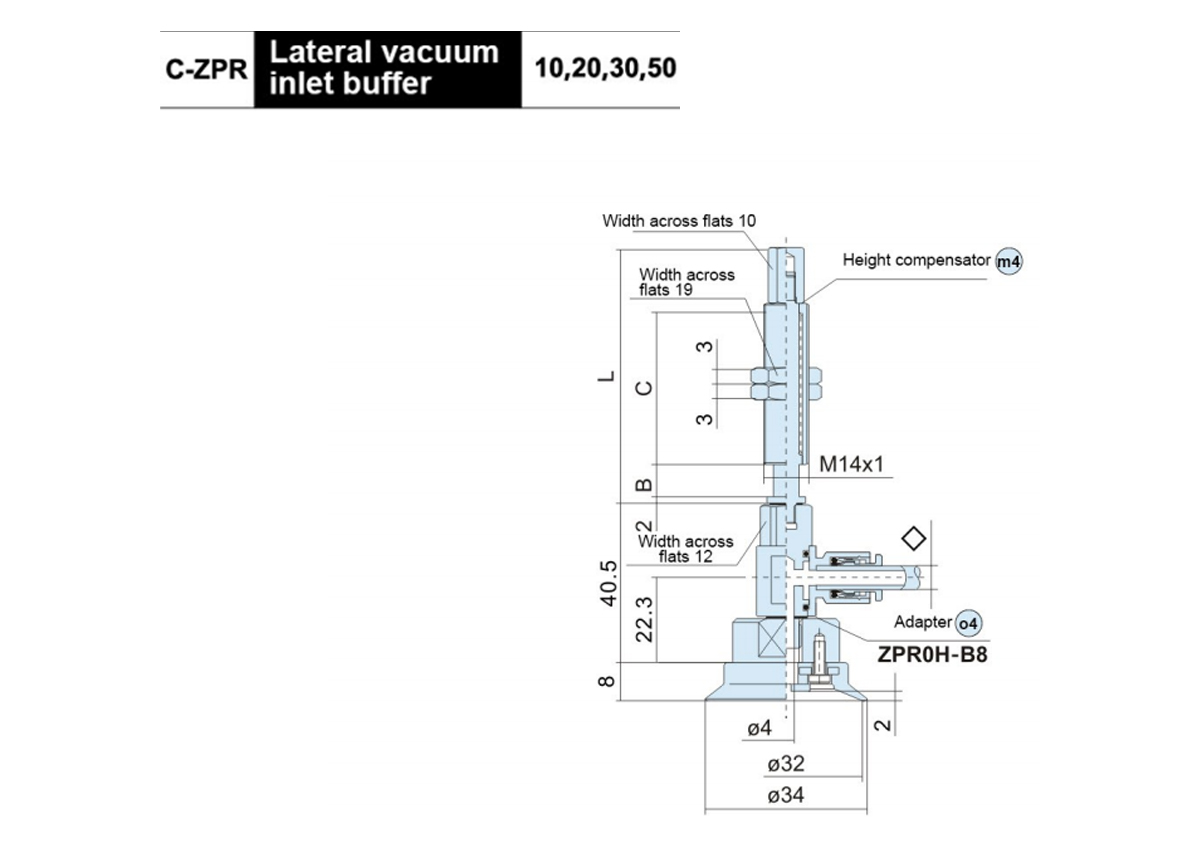

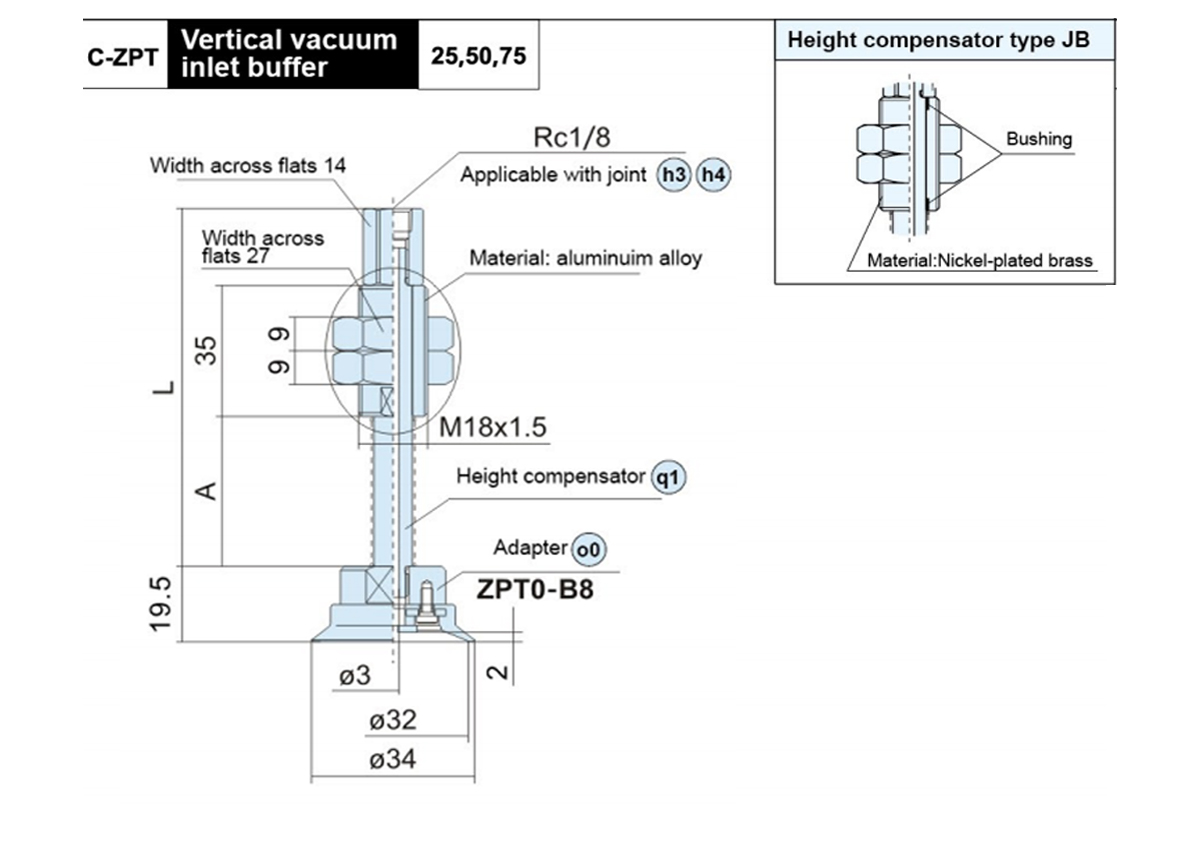

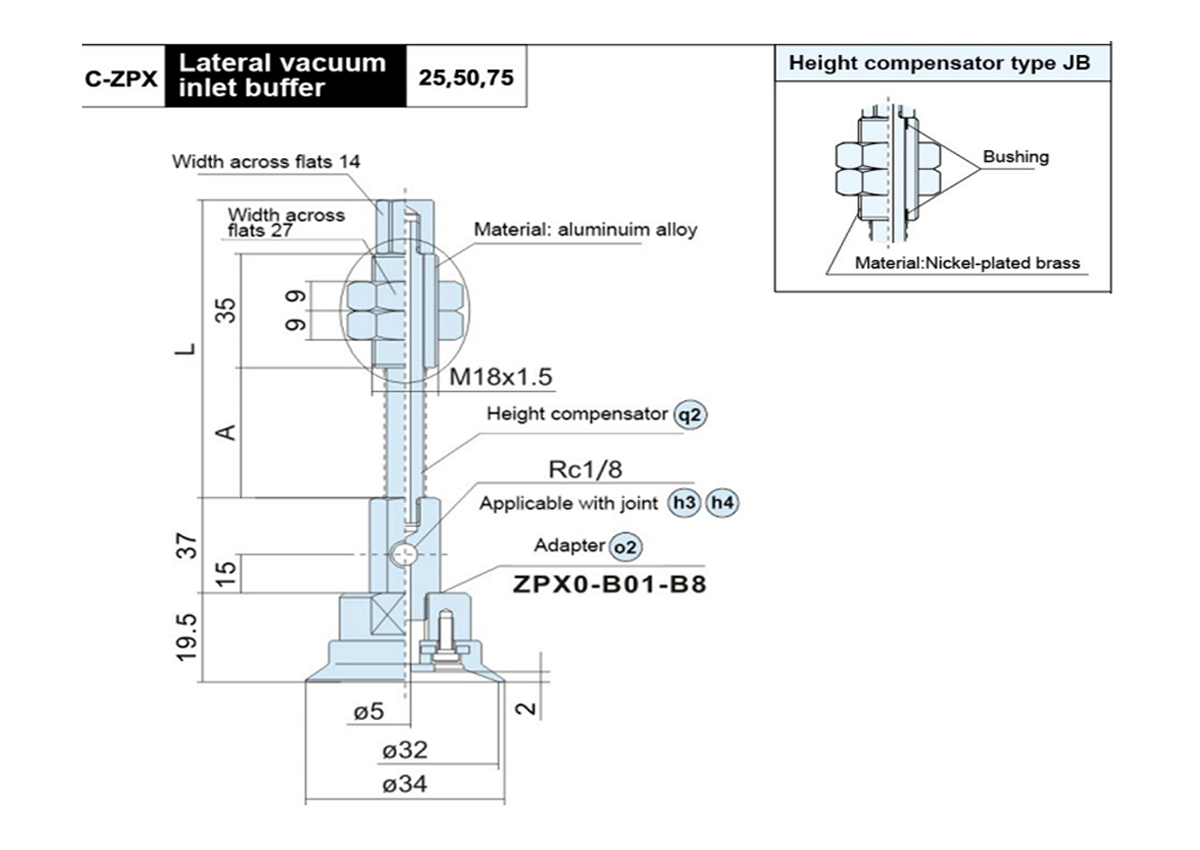

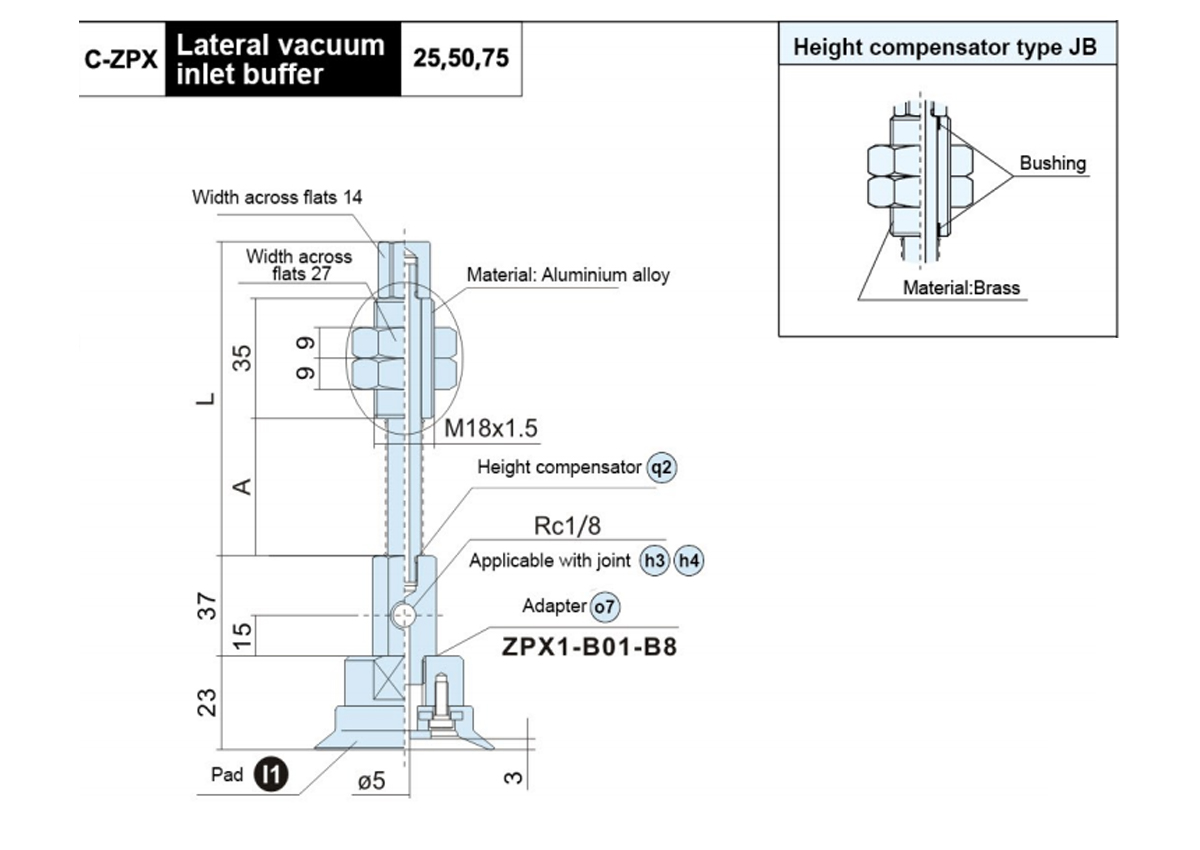

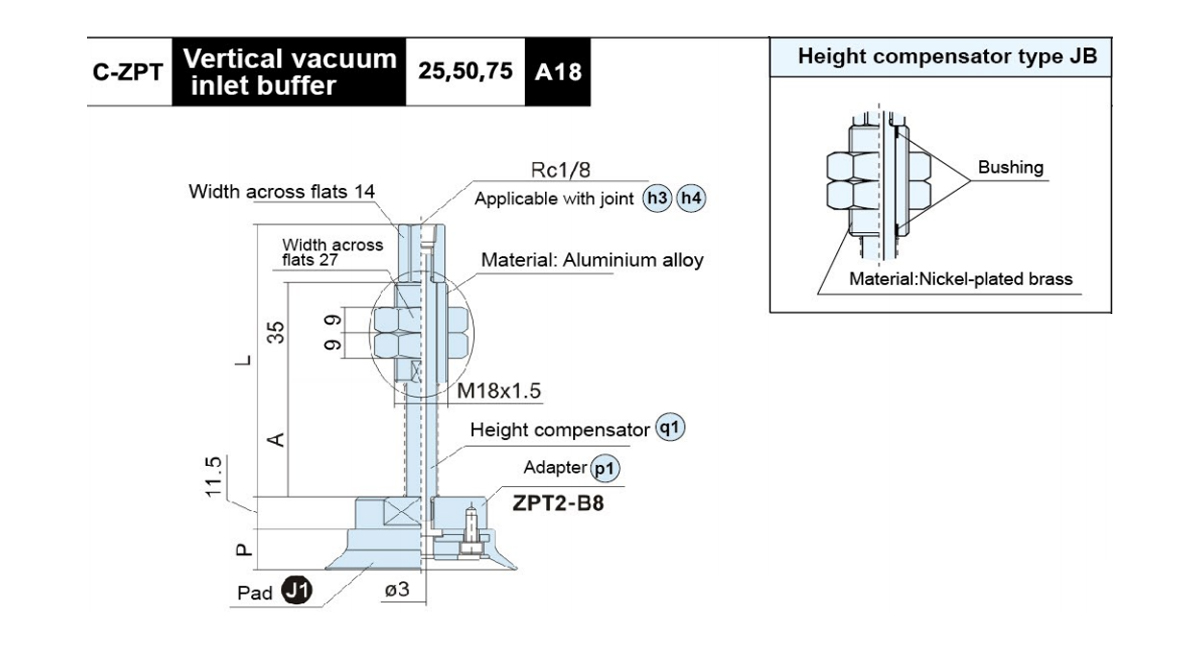

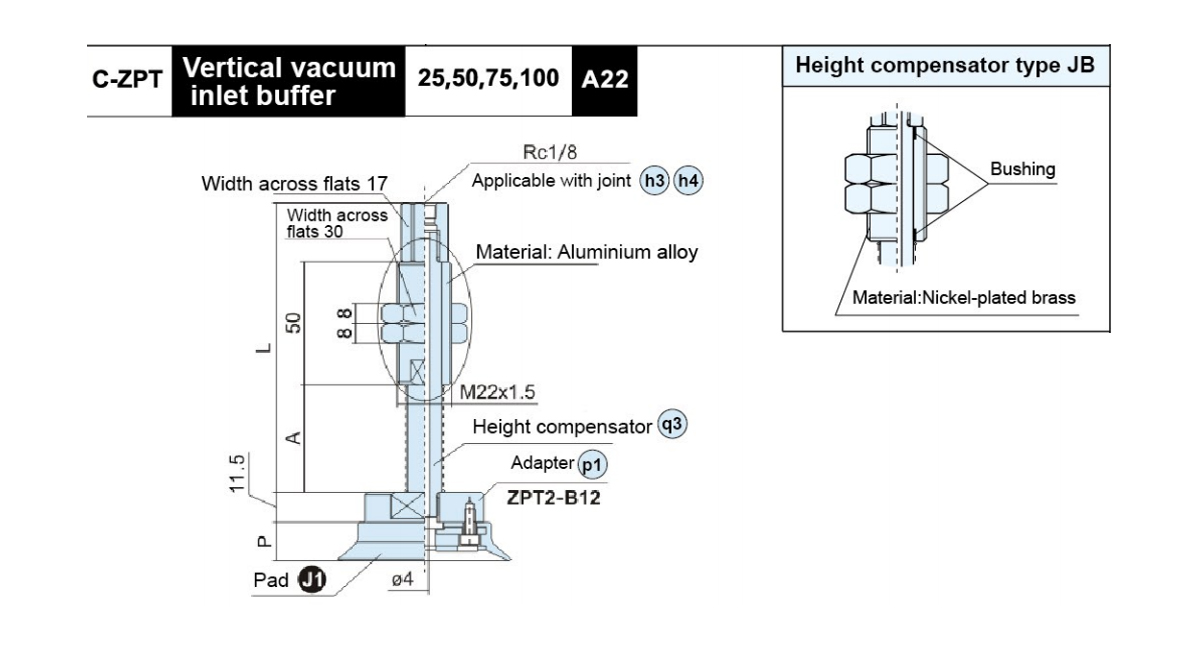

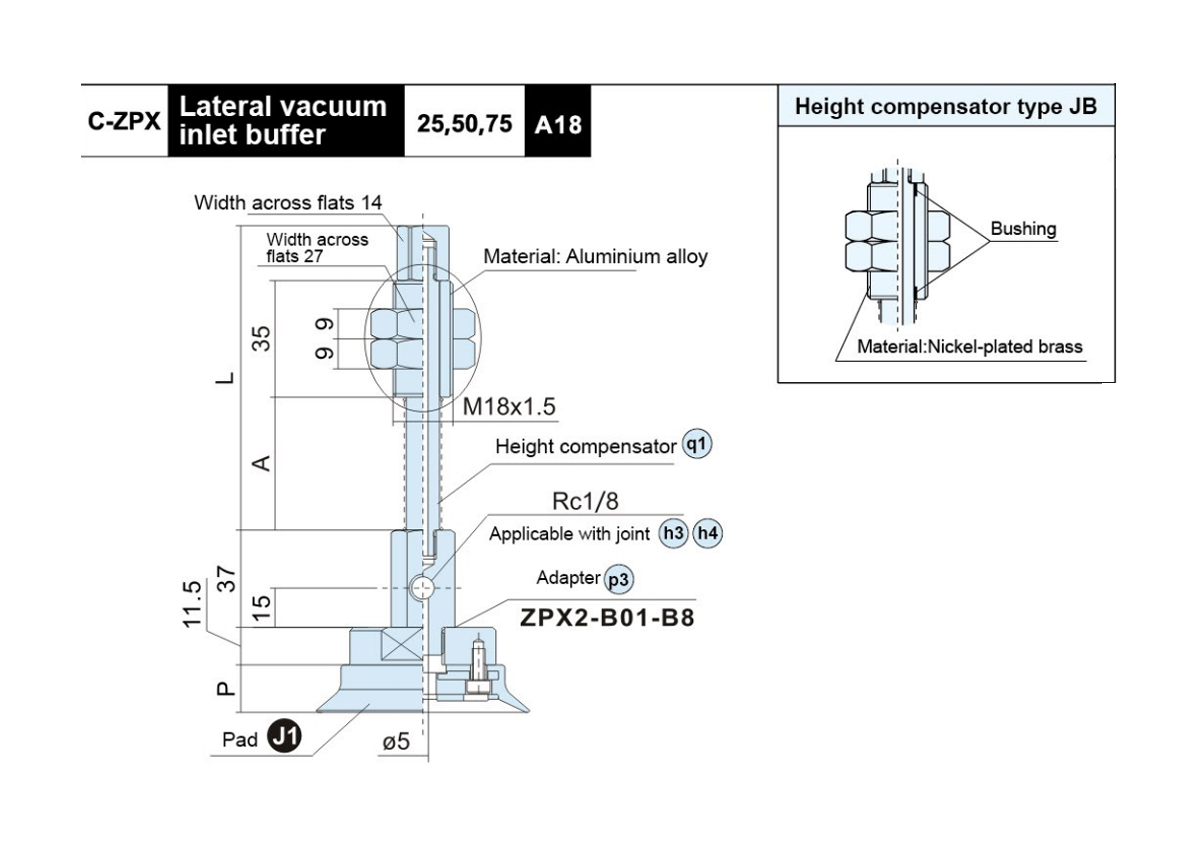

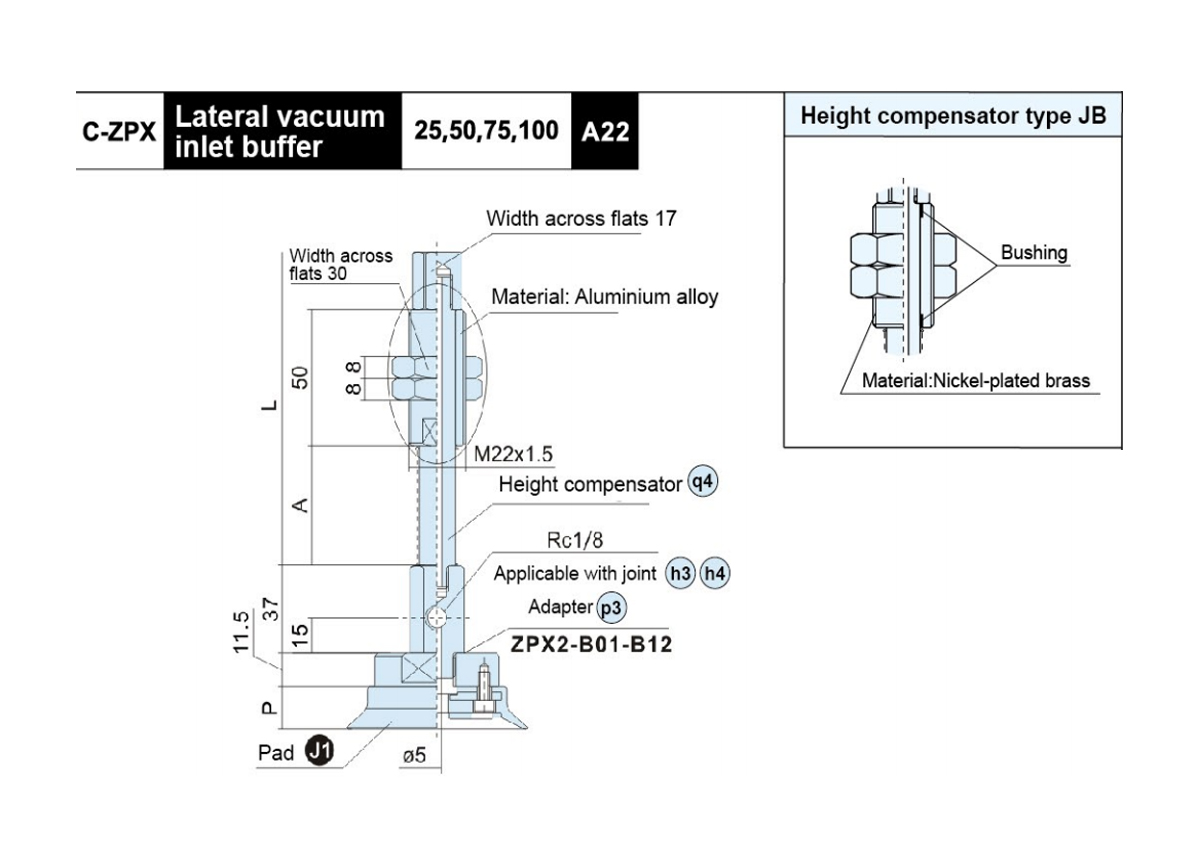

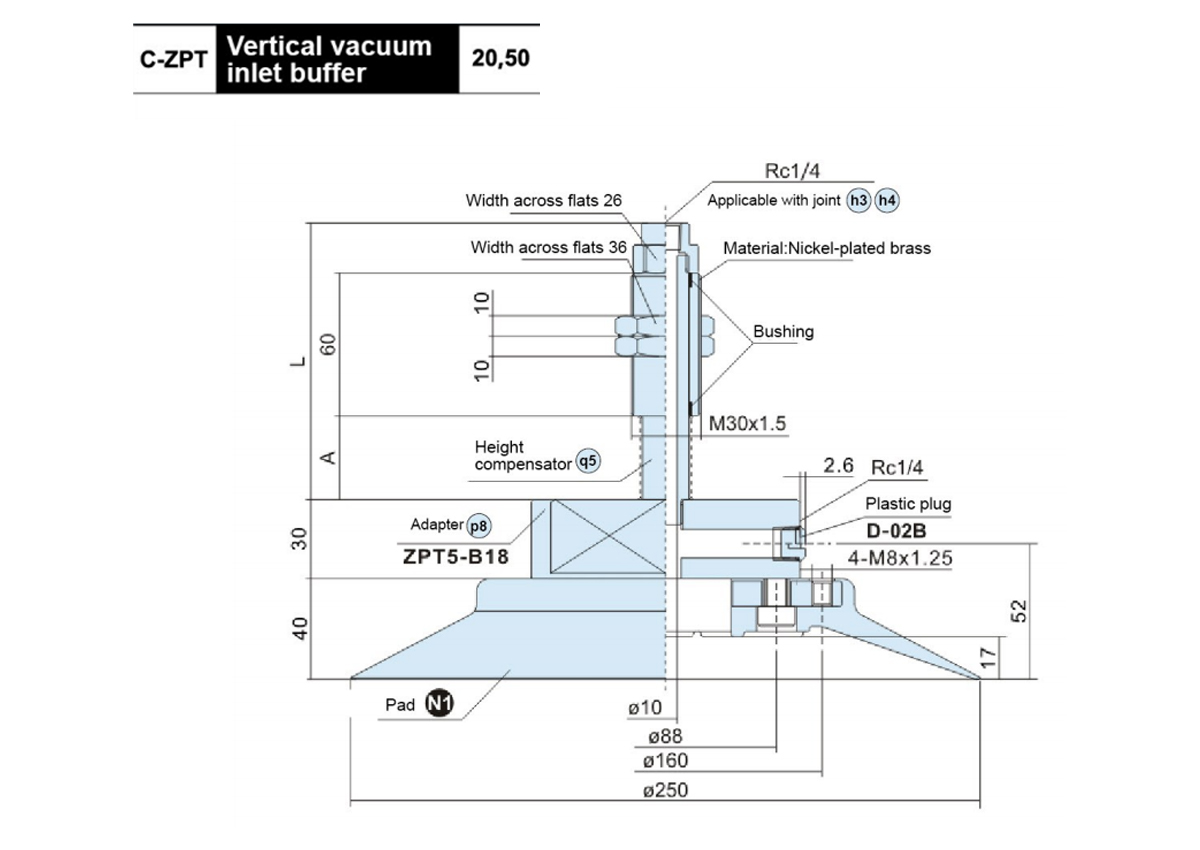

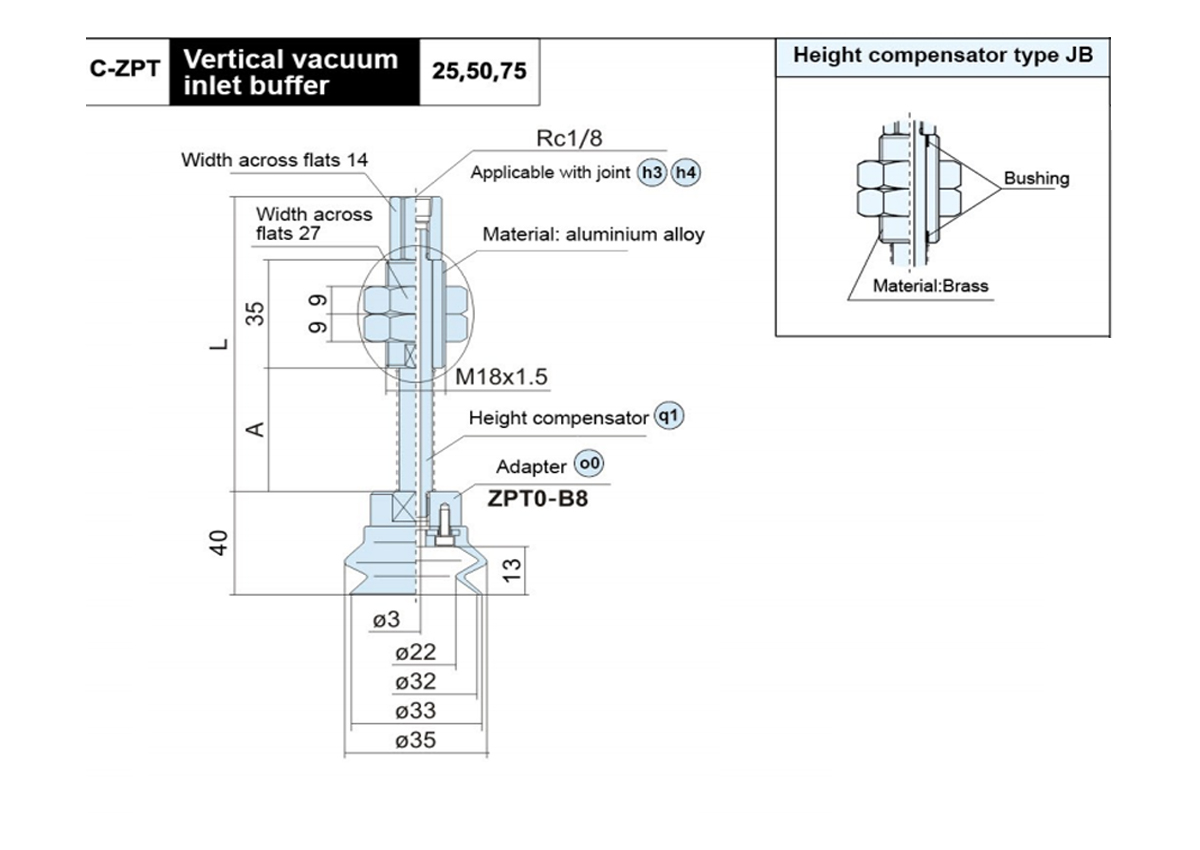

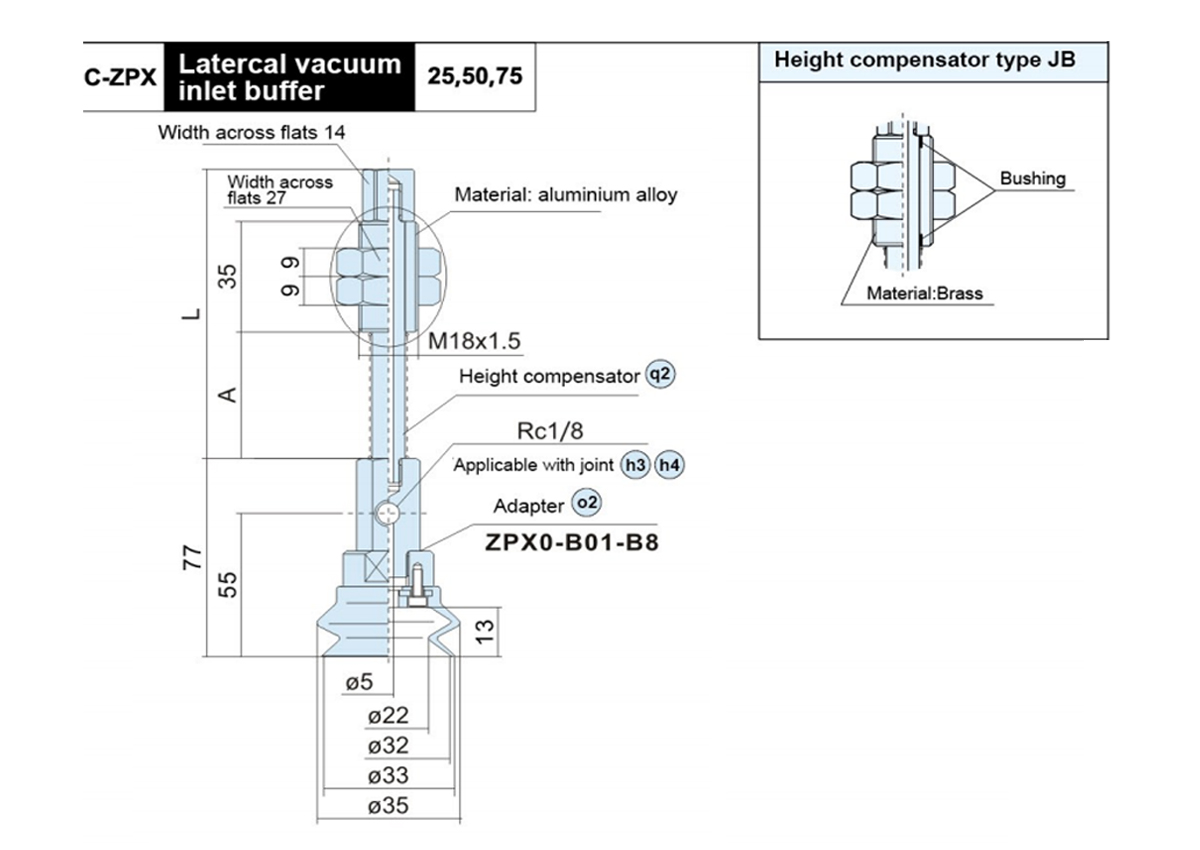

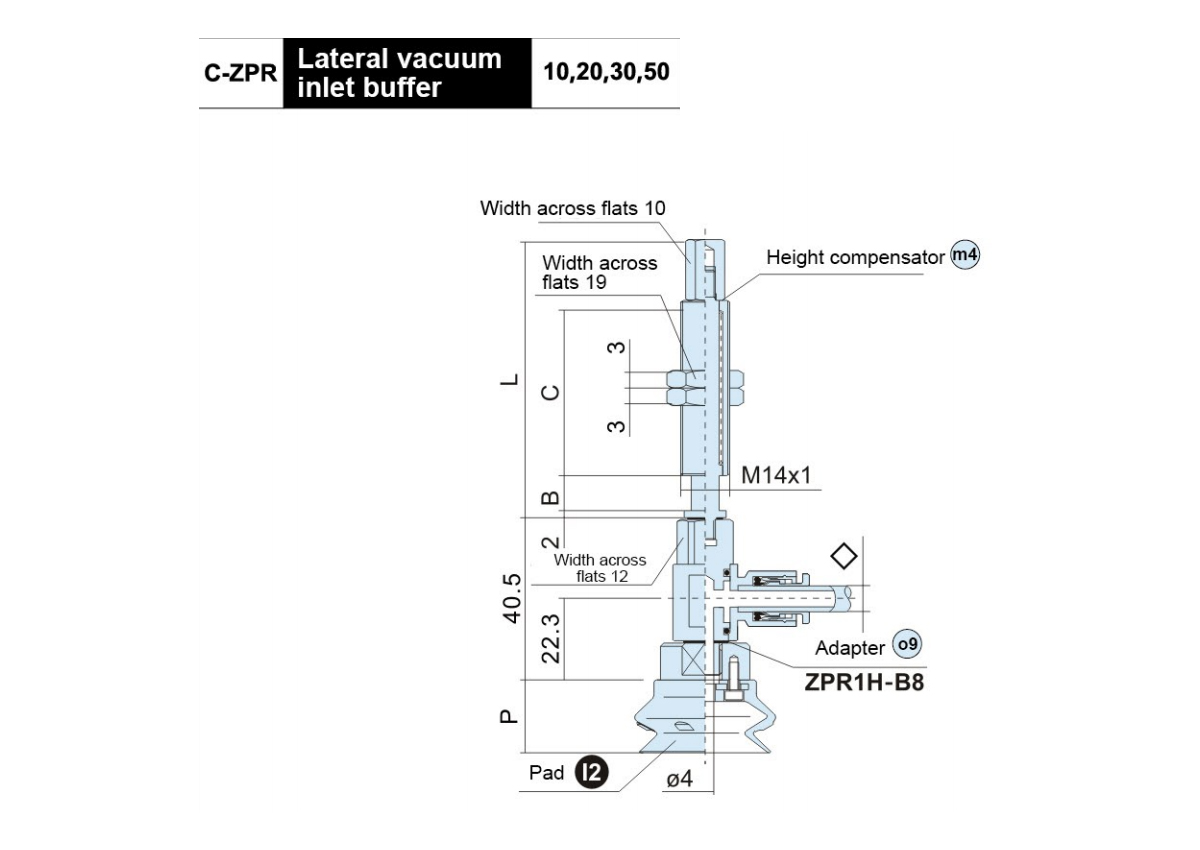

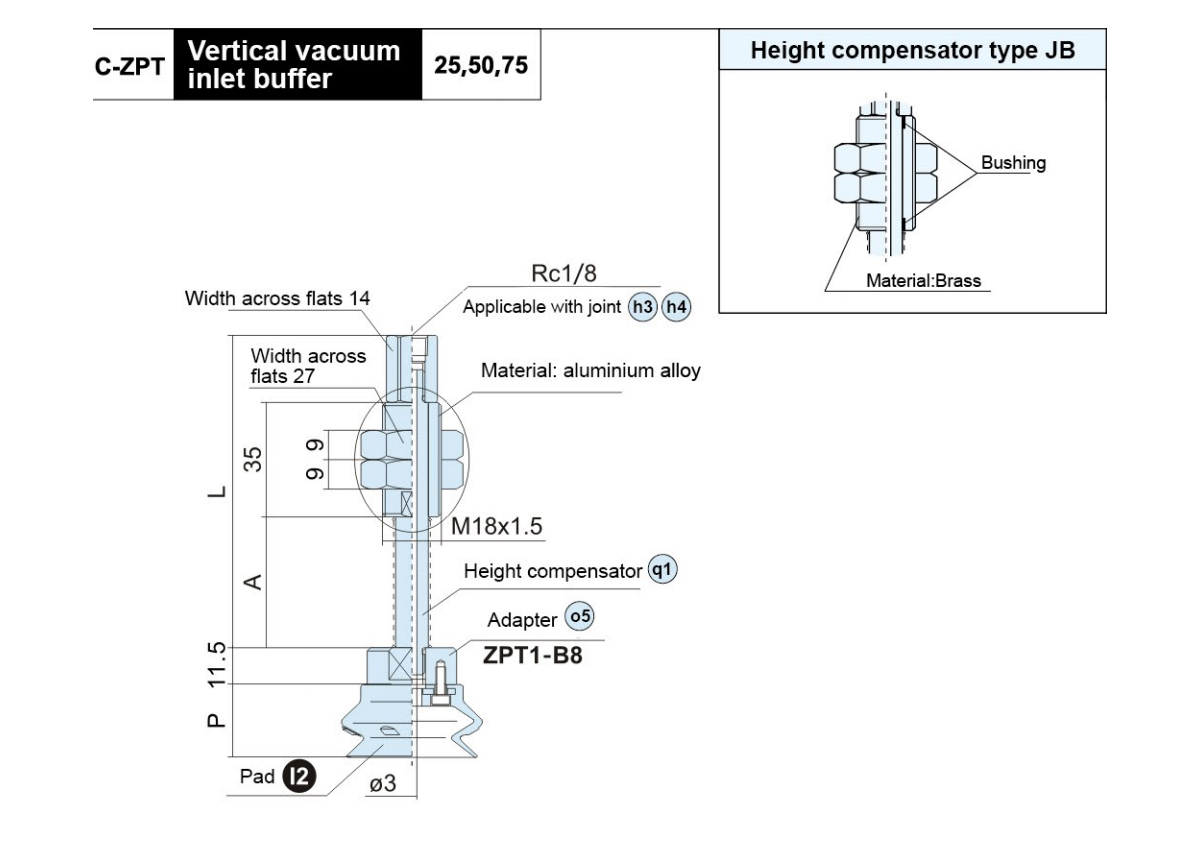

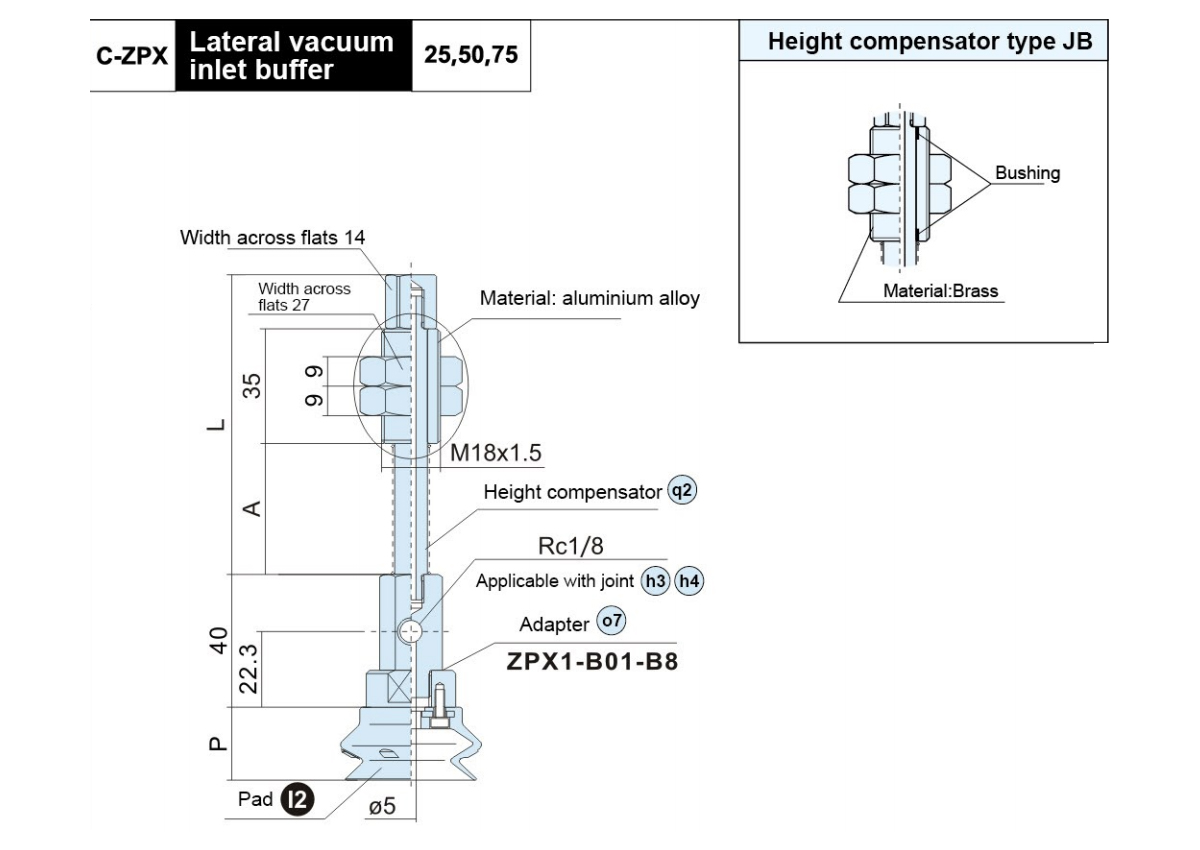

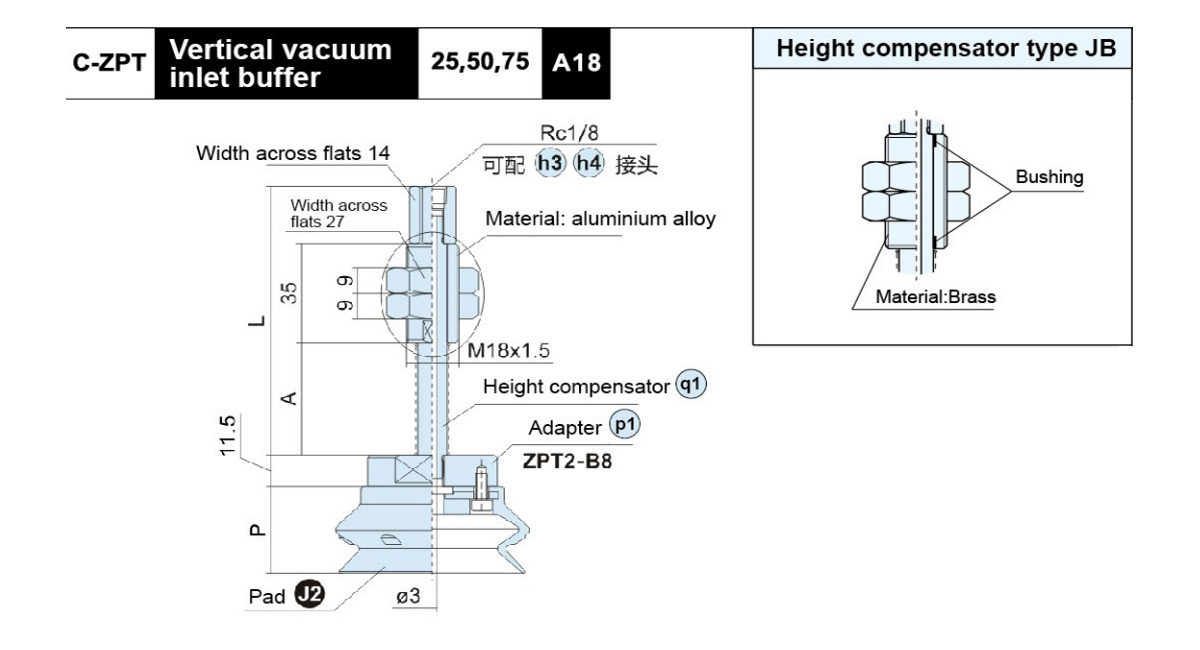

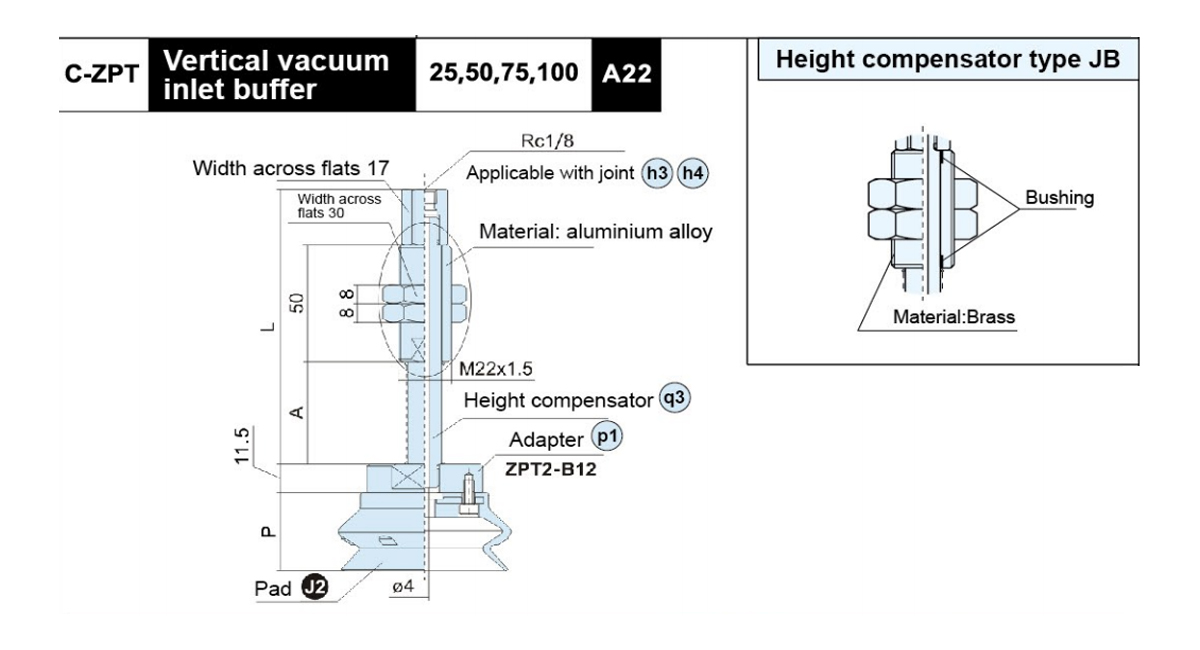

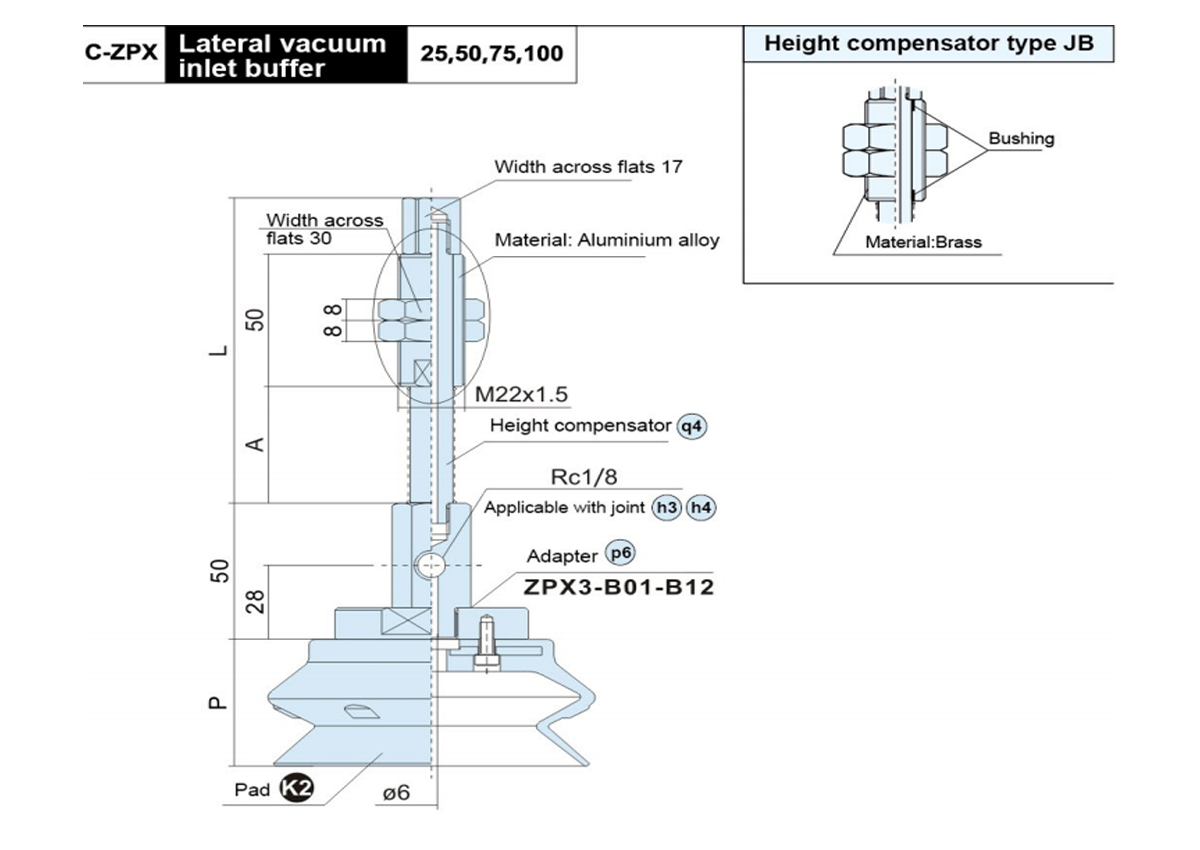

Embedded buffer mechanism: The built-in buffer bracket element is the essence of the design. Its core value lies in absorbing the impact kinetic energy at the moment of contact and the low-frequency vibration during operation, significantly reducing the mechanical stress on the workpiece surface, suction cup structure and upstream equipment.

System integration matching: The design of the overall solution gives priority to the convenience of integration with mainstream automation platforms (such as robot arm ends and guide rail slides), reducing the complexity of engineering adaptation for field deployment.

Robustness and durability: The selection of components and structural design focus on improving long-term service performance in continuous heavy-load cycles, potential collisions and typical industrial environments, ensuring a stable operating cycle.

Vacuum sealing performance guarantee: The suction cup lip structure and material formulation are optimized for heavy-load applications, striving to achieve and maintain an effective vacuum sealing state on complex surfaces (allowing a certain degree of unevenness).

Universal application scenarios: The design concept of this series makes it naturally suitable for a variety of industrial scenarios involving metal sheets, large composite materials, heavy packaging units, molds, etc. that require strong and gentle grasping and release.