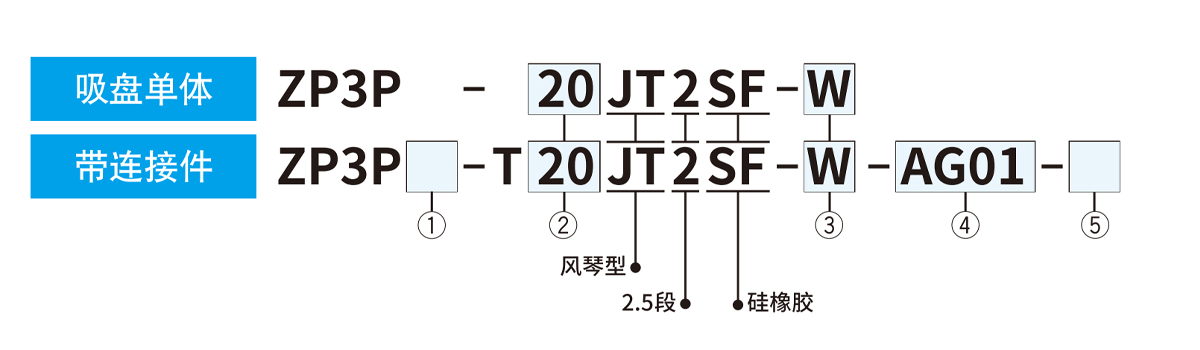

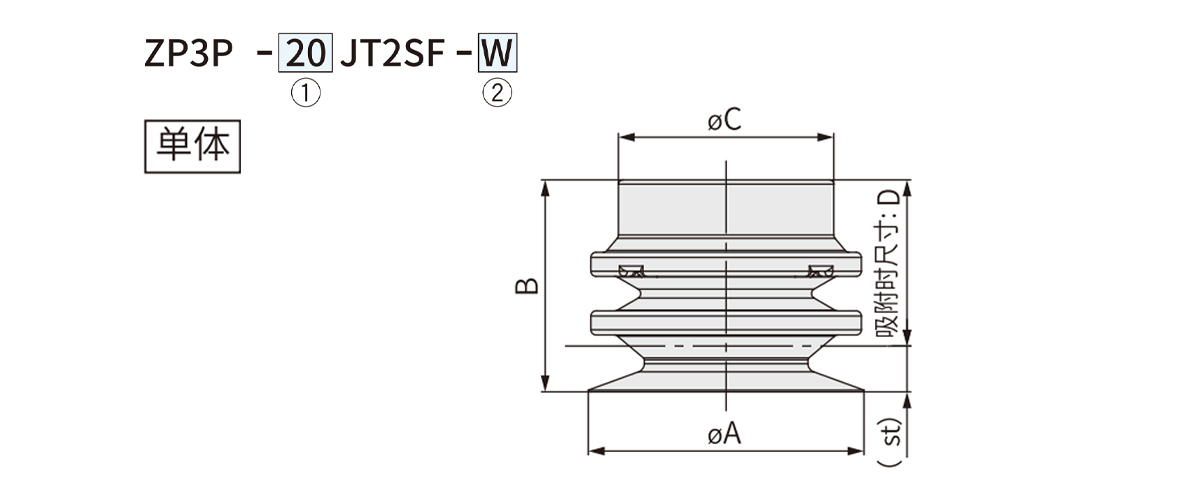

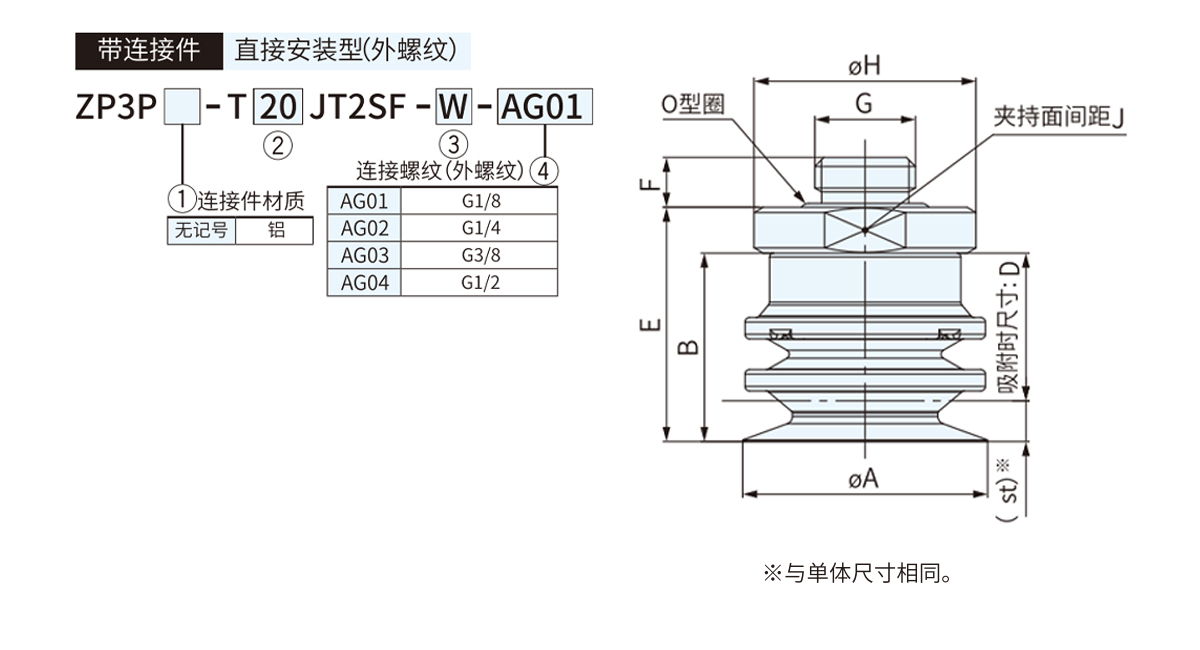

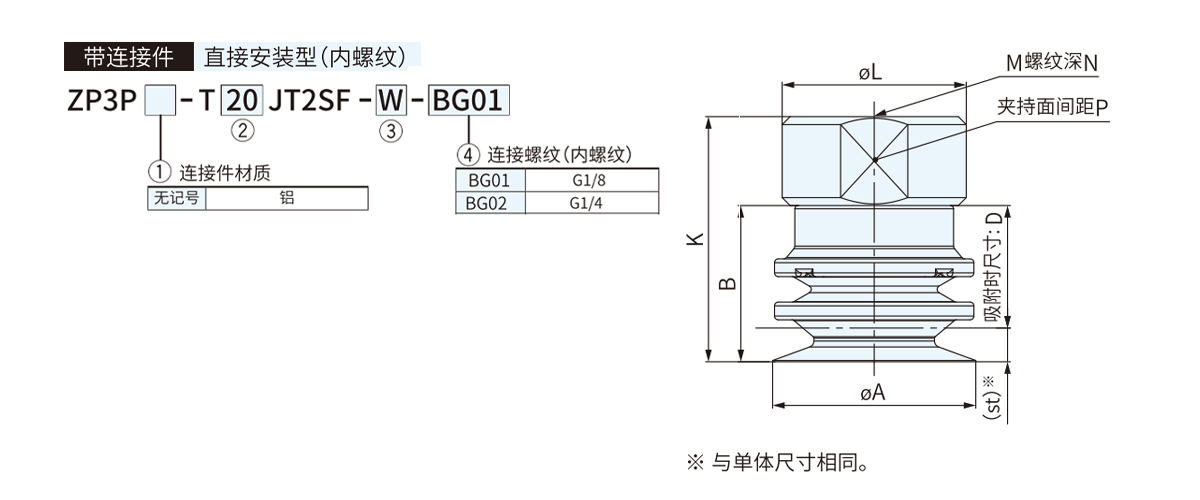

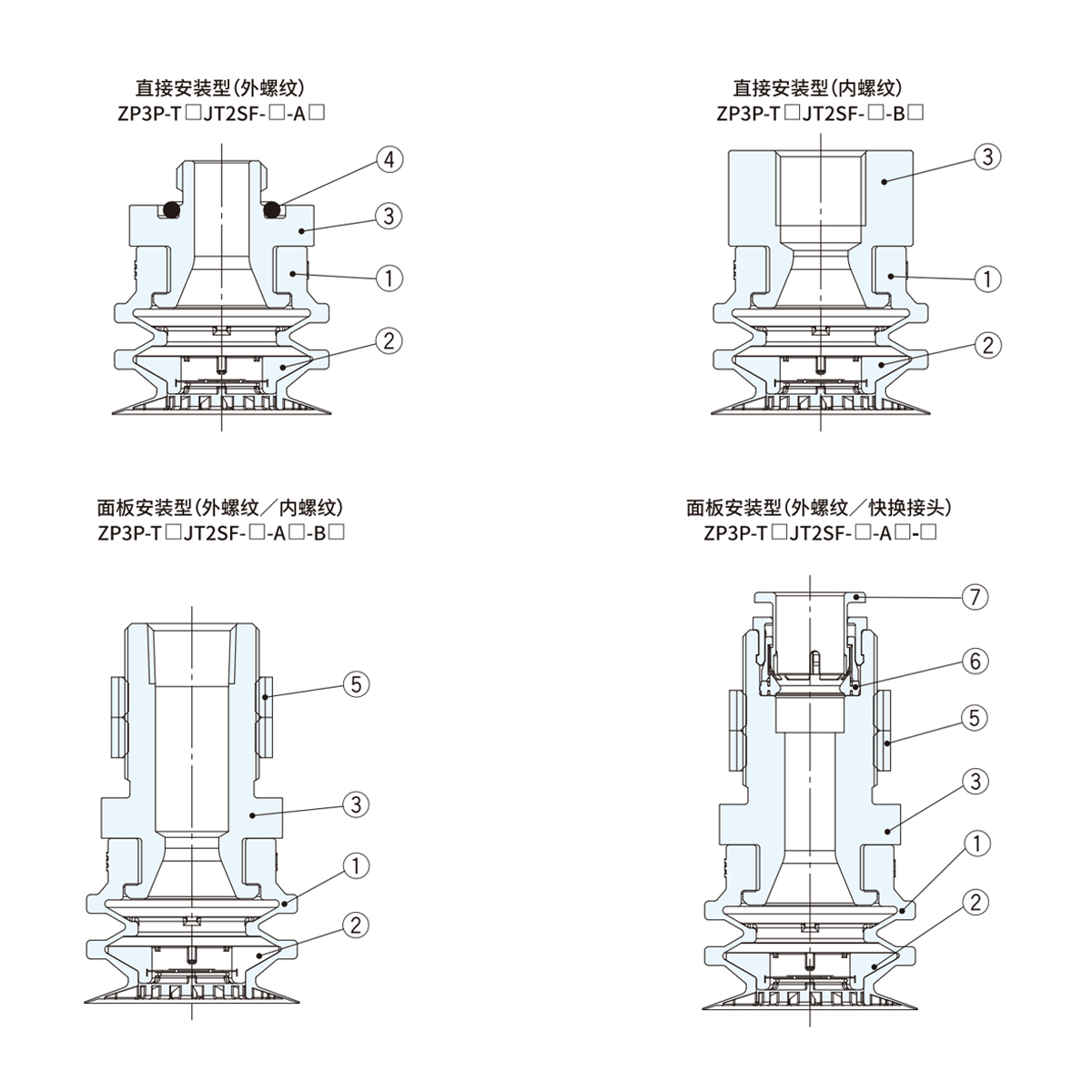

ZP3P Series Vacuum Suction Cup

ZP3P-JT Series 2.5 Section Organ Type

ZP3P-JT Series 2.5 Section Organ Type is a flexible connection component with a special structure, mainly used in complex working conditions that require medium compensation capabilities. Its unique "2.5-section" design is an innovative evolution of the basic organ structure, aiming to balance efficiency and control.

The core features are as follows:

The core of structural evolution: Its design concept is derived from the standard organ-type structure, but through specific transition and morphological processing, a unique "2.5-section" hierarchy is formed. This is not a simple superposition of sections, but a coordinated optimization of internal flow field distribution and external displacement adaptability.

Medium compensation balance point: The "2.5-section" structure is the key embodiment of its functional positioning. Compared with conventional designs, it provides more abundant axial and lateral compensation capabilities beyond the basic section, while striving to maintain the overall stiffness and stability of the structure through specific morphological constraints, and seeks a balance between larger compensation requirements and space/control restrictions.

Enhanced dynamic adaptability: This special configuration enhances the rationality of the internal stress distribution of the component when it is subjected to complex and irregular displacements (such as multi-axis offsets and angular deflection combinations), and improves the potential threshold of dynamic fatigue life. Its fold morphology has been specially considered to be more conducive to dispersing concentrated stress during movement.

Efficiency and space considerations: The compromise design of "2.5 segments" is essentially to strive to obtain partial compensation efficiency close to that of a higher number of segments without significantly increasing the axial installation length. This makes it uniquely applicable in application scenarios where the installation space is limited but the compensation capacity of the basic segment is required to exceed that of the basic segment.

Process fusion embodiment: The realization of this structure depends on the combination of specific molding processes and material processing technologies. Its complex fold transitions and the integration of internal supports (if any) reflect specific requirements for manufacturing accuracy and material performance applications.

Multi-field application potential: This type of structure is particularly suitable for complex pipeline connection scenarios that require medium to high compensation capabilities and have control requirements for the contour size, dynamic stability or specific flow field disturbances of the components. It is commonly found in some industrial system connection parts that are sensitive to spatial layout or have diverse movement modes.