Pneumatic Silencer

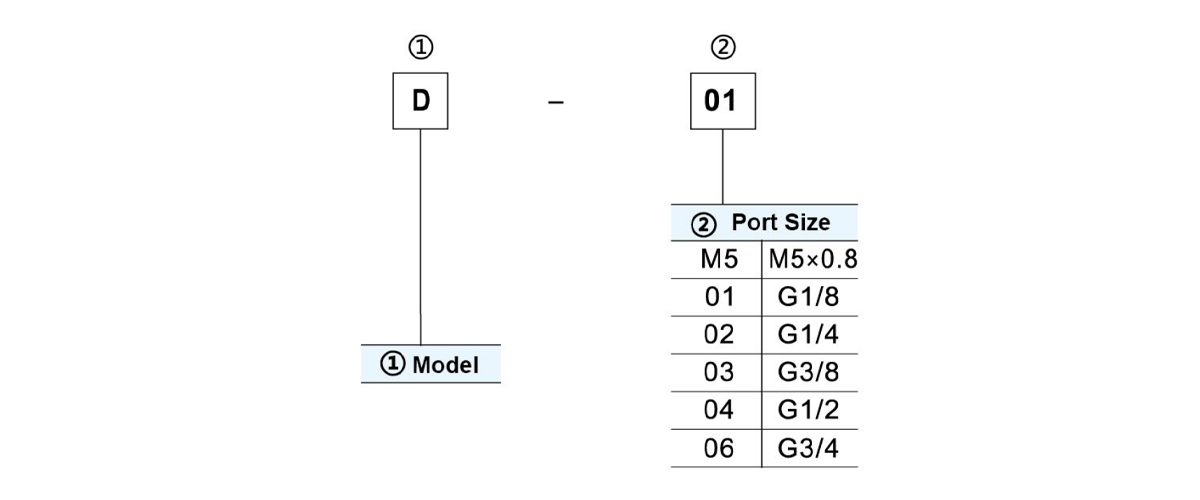

D Series Pneumatic Silencer

The D series pneumatic silencer is the core component of exhaust noise control for industrial equipment. It achieves passive attenuation of wide-band noise energy by optimizing the exhaust flow field and acoustic impedance matching. Its design concept focuses on system compatibility and environmental adaptability, and is suitable for the terminal noise reduction needs of various pneumatic circuits.

Key features

Multi-level noise reduction mechanism: built-in asymmetric medium structure, weakening the peak of medium and high frequency noise energy through turbulent dissipation and acoustic phase interference principle, and alleviating exhaust whistling phenomenon.

Dynamic flow resistance control: geometric flow channel design takes into account low back pressure characteristics and acoustic energy attenuation efficiency, reducing the risk of interference with the response speed of actuators.

Environmental tolerance architecture: the shell material has chemical inertness and particle tolerance, and maintains the functionality of the pore structure under non-clean conditions such as oil mist and dust.

Passive operation paradigm: pure mechanical operation mode avoids external energy dependence, integrates maintenance-free design logic, and adapts to the long-term deployment of distributed industrial equipment.

Universal interface adaptation: Standard threaded interface supports the topological expansion of mainstream pneumatic components, and the modular structure allows series installation to meet the sound pressure level control requirements of high-flow scenarios.