Pneumatic Silencer

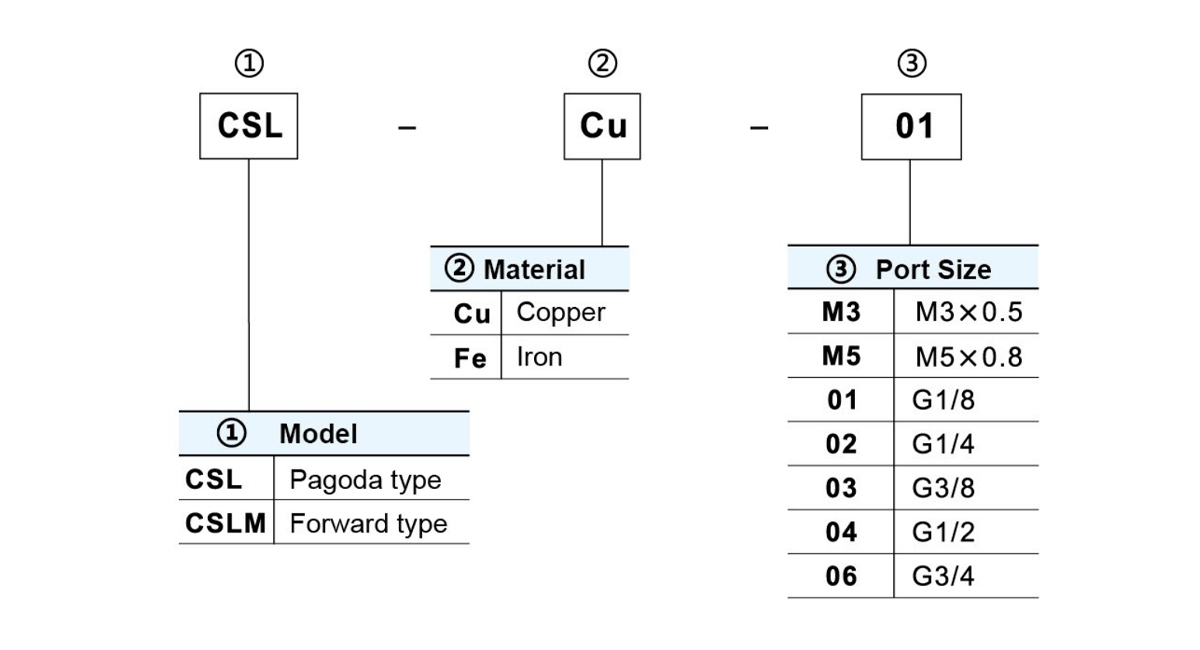

CSL Series Pneumatic Silencer

CSL series pneumatic silencers are devices designed for exhaust noise control of industrial pneumatic systems. They are mainly used to reduce the high-frequency airflow whistling generated when compressed air is discharged quickly.

Core noise reduction function: Through the special internal flow channel structure and sound-absorbing medium, the noise energy generated during the release of high-speed airflow is effectively attenuated, significantly improving the sound pressure level of the working environment.

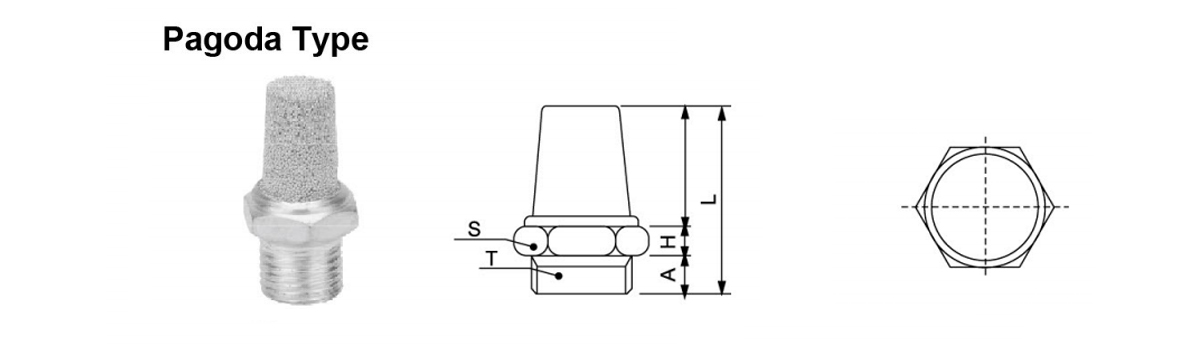

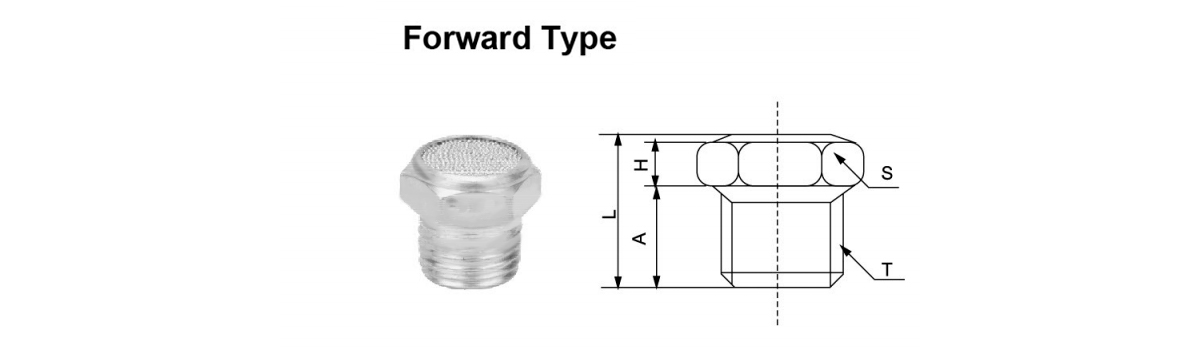

Engineering adaptability: Its compact design is easy to integrate into the exhaust ports of various standard pneumatic actuators (such as cylinders, valve islands) or pipelines to meet common industrial installation space constraints.

Fluid compatibility guarantee: The structural material usually considers the influence of oil mist, condensed water and particulate impurities in the industrial compressed air environment to ensure durability and patency under typical working conditions.

Pressure adaptability: The working pressure range covers the operating range of conventional pneumatic systems, can adapt to different exhaust flow requirements, and maintain a balance between system response and silencer effect.

Maintenance and life: Modular design usually considers maintenance-free or low-maintenance requirements, and the internal core noise reduction components have a long service life under standard use conditions.