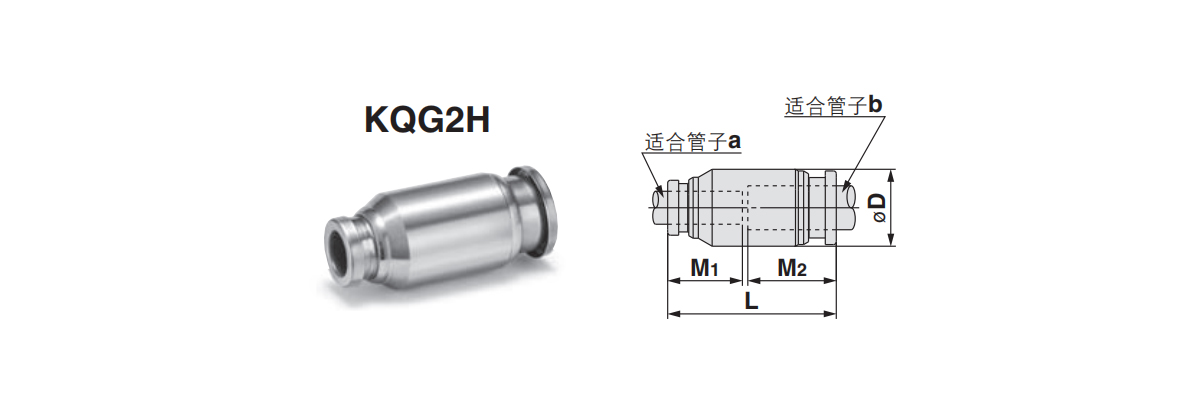

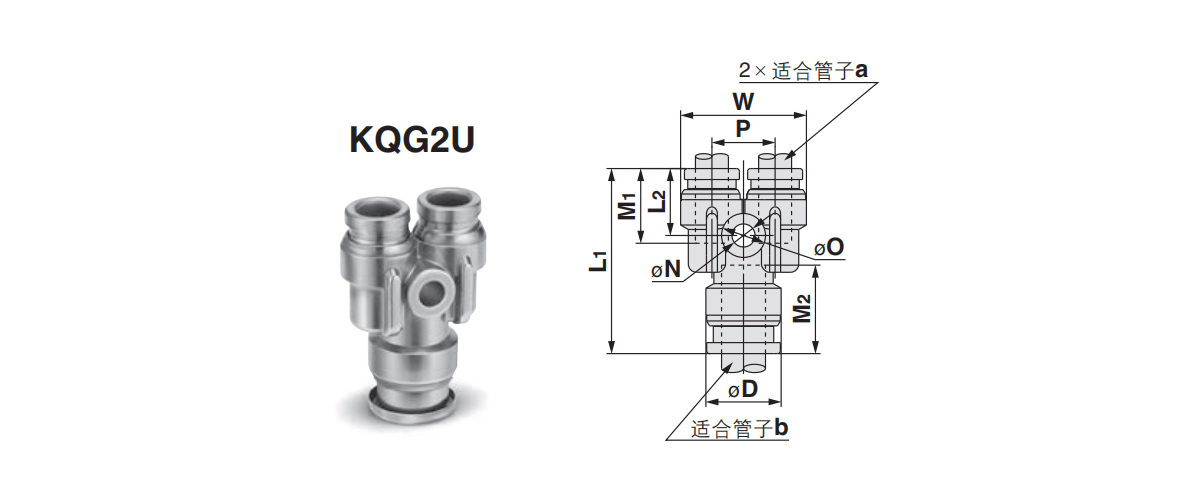

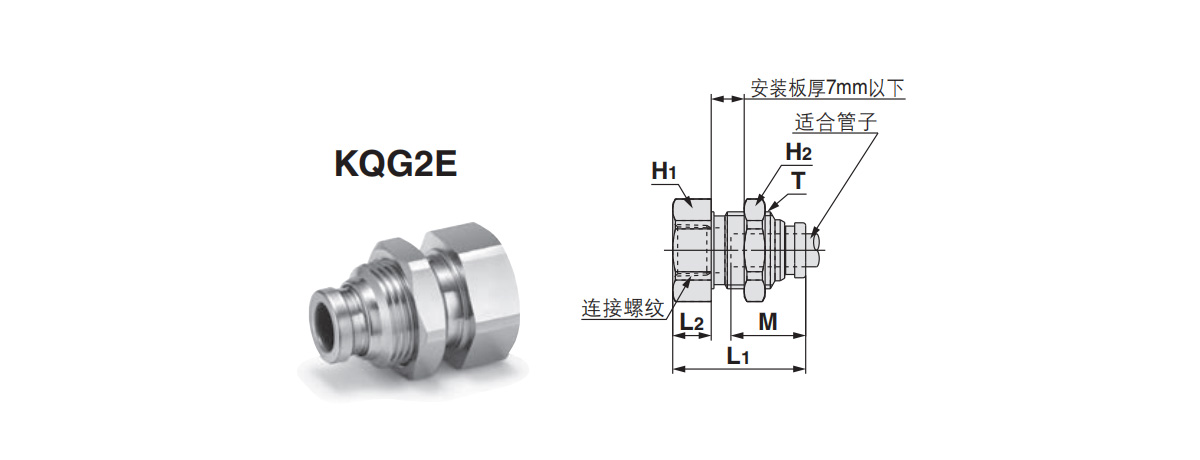

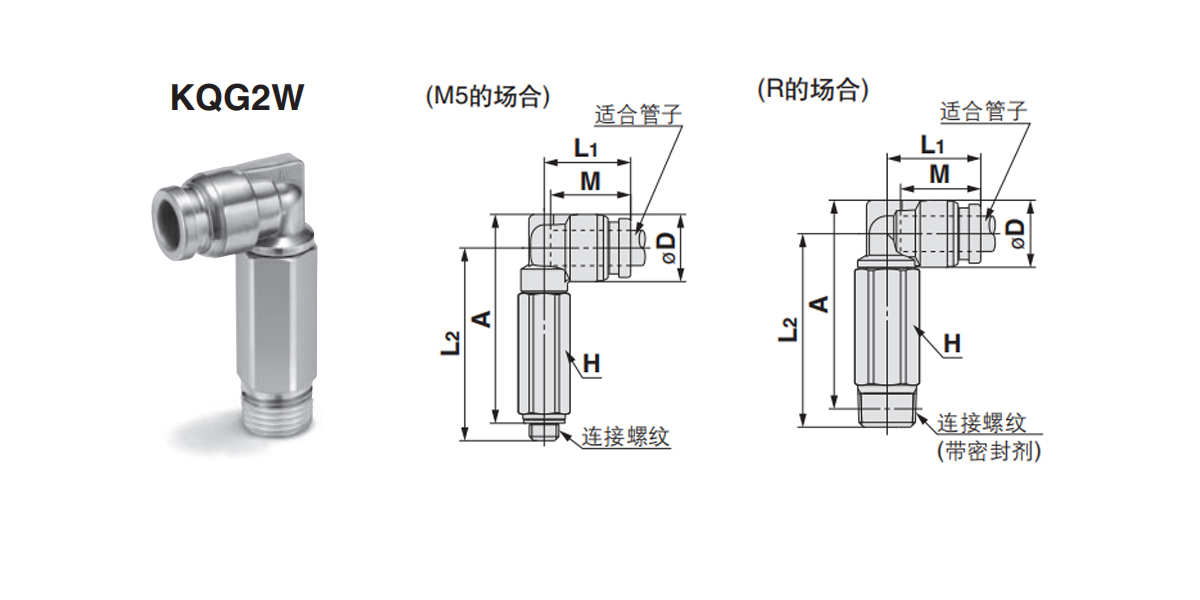

Stainless Steel One Touch Fitting

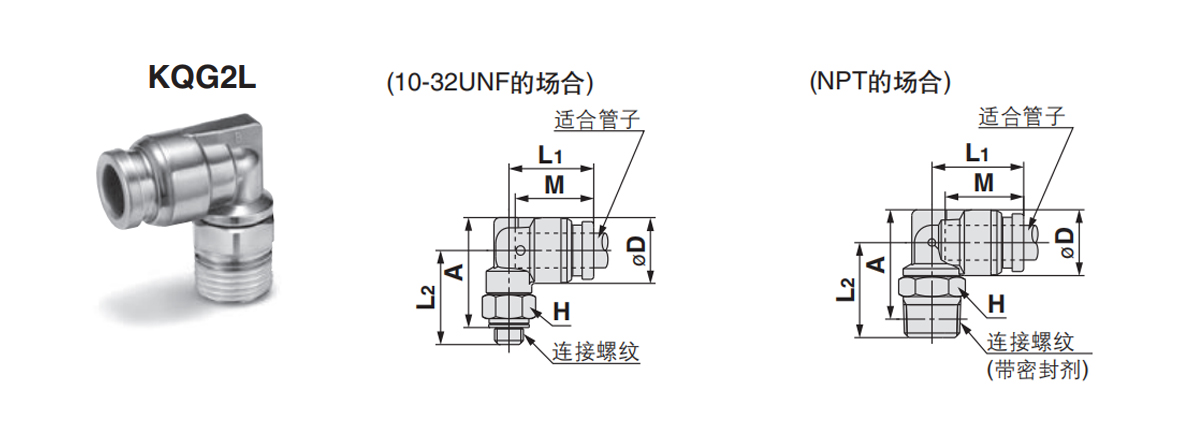

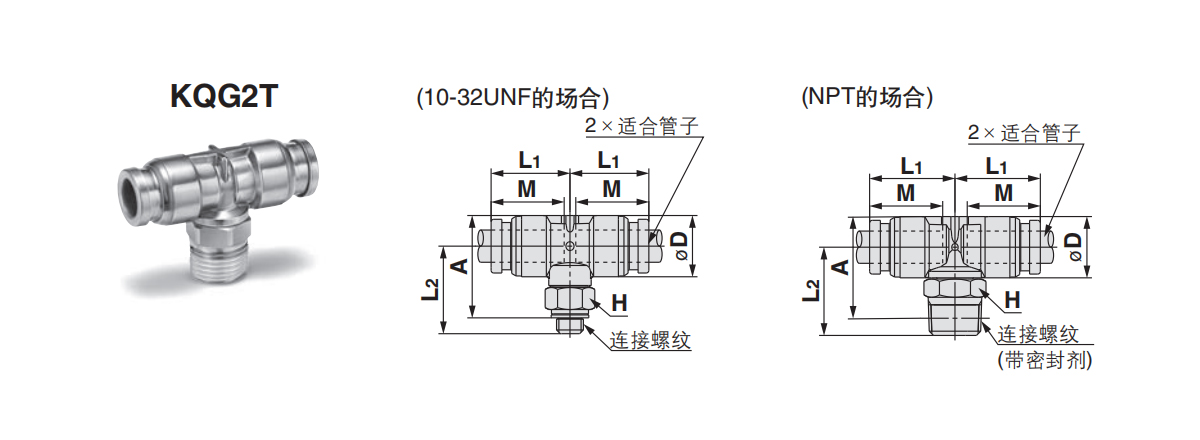

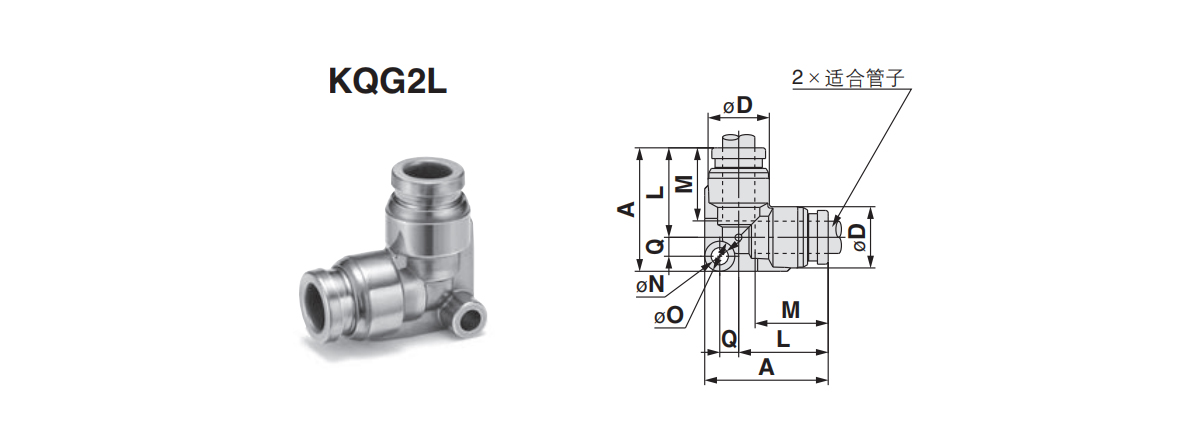

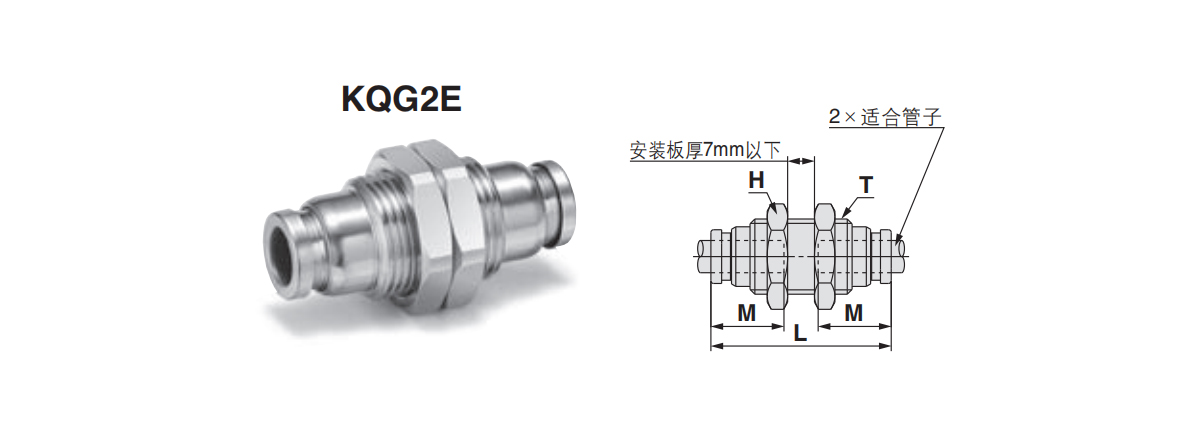

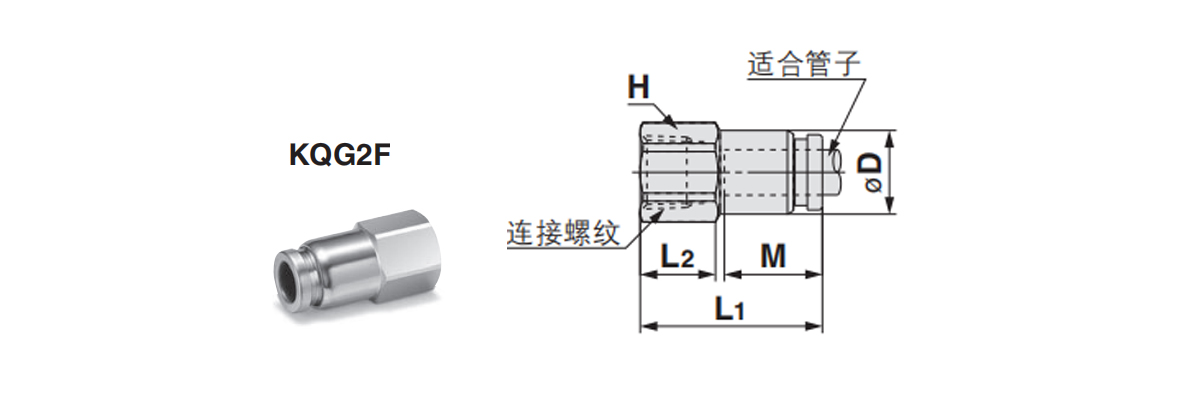

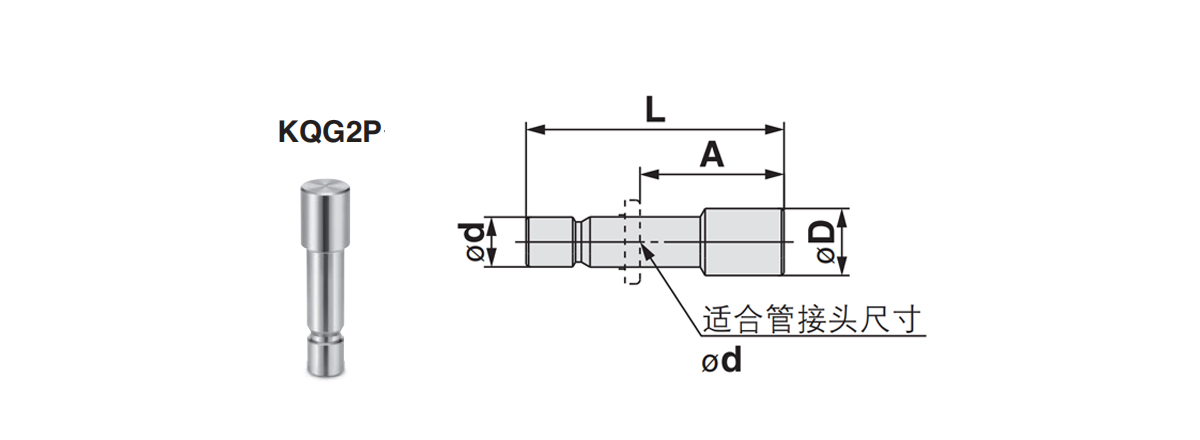

KQG2 Series SUS316 Stainless Steel one touch fitting

KQG2 series SUS316 stainless steel one touch fittings are designed for harsh industrial environments. They are made of surgical instrument grade SUS316 stainless steel to achieve fast sealing connection and disconnection of media channels. Its structure combines high corrosion resistance with easy operation, and is suitable for fluid control systems with strict requirements on cleanliness and reliability.

Core features

Medical grade corrosion resistance base

The main body material is SUS316 ultra-low carbon austenitic stainless steel. The surface corrosion resistance layer is strengthened by passivation process, which significantly inhibits chloride ion corrosion and intergranular corrosion, and is resistant to acid, alkali solvents and high salt spray environments.

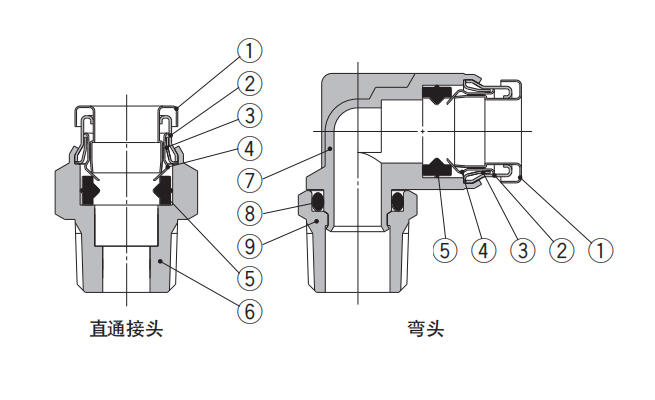

Single action locking mechanism

Built-in self-locking buckle structure, a single push action can complete the bidirectional sealing of the pipeline, without auxiliary tools or rotation operation, greatly shortening the equipment maintenance and pipeline reorganization time.

Full range dynamic sealing guarantee

The multi-stage sealing component uses composite polymer materials, and the elastomer compensation system can absorb pipeline vibration and thermal expansion and contraction deformation, maintaining zero leakage under extreme pressure fluctuation conditions.

Non-polluting flow channel design

The full-diameter flow channel has no dead angle structure, combined with electrolytic polishing inner wall treatment, to prevent particle retention and biofilm growth, meeting the fluid integrity requirements for high-purity media transportation.

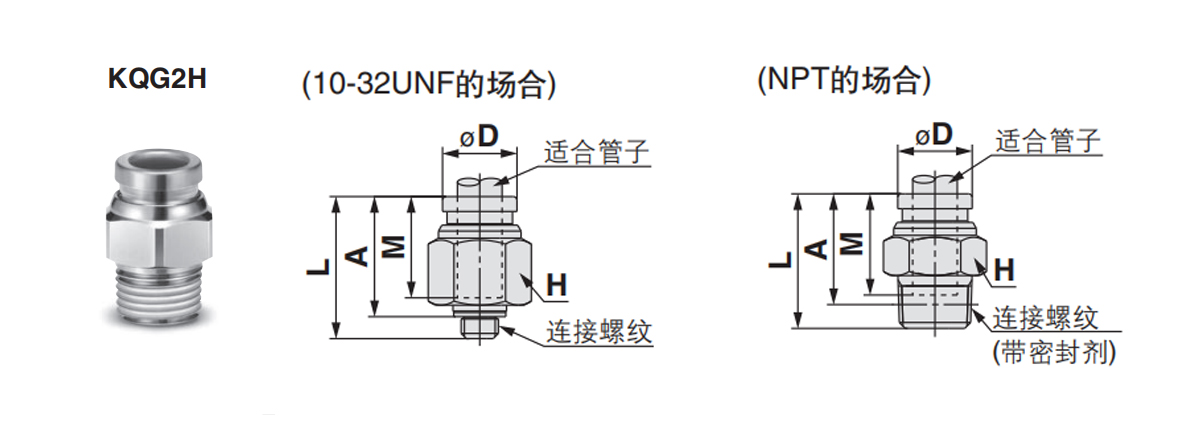

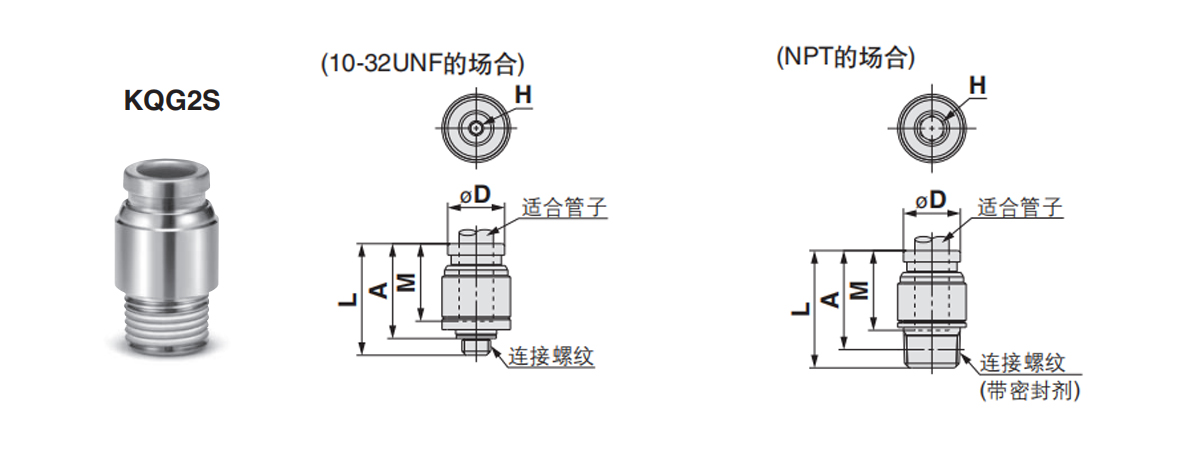

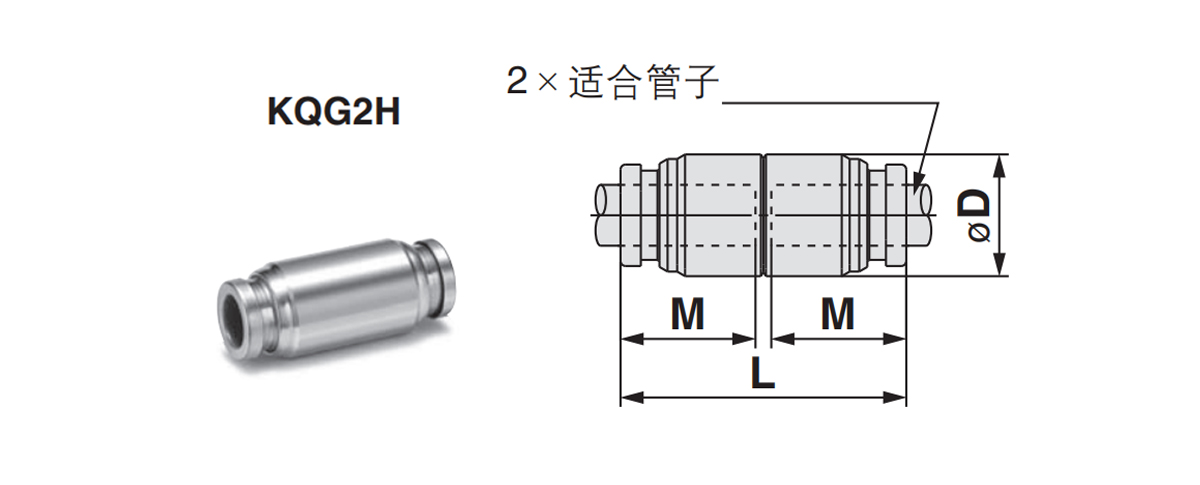

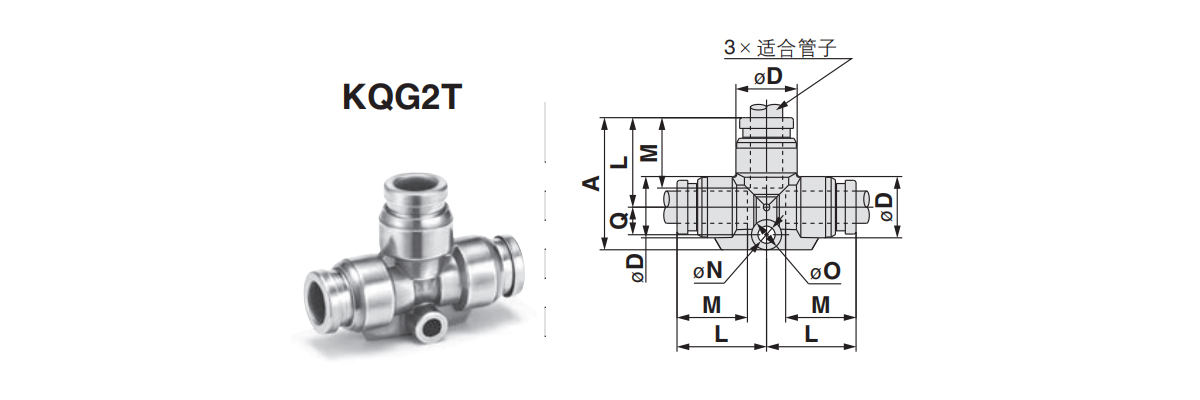

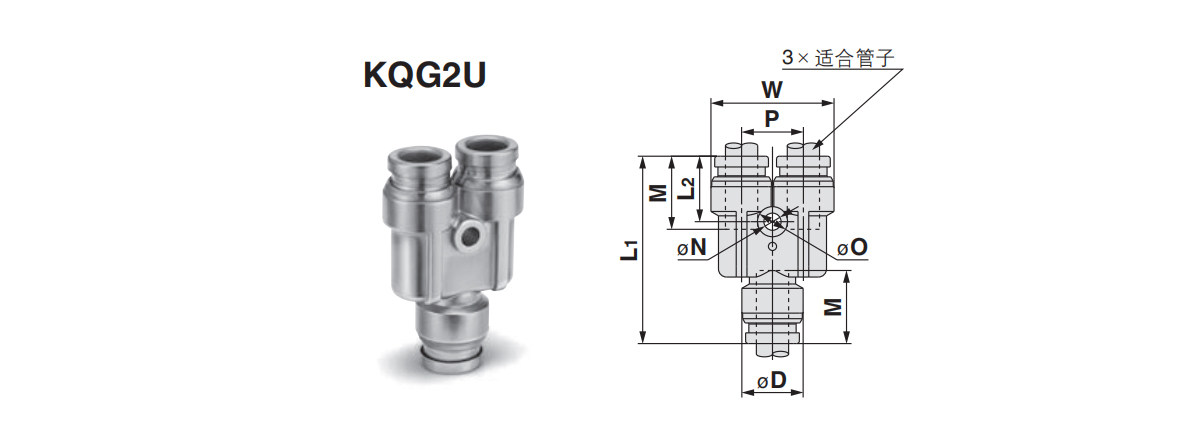

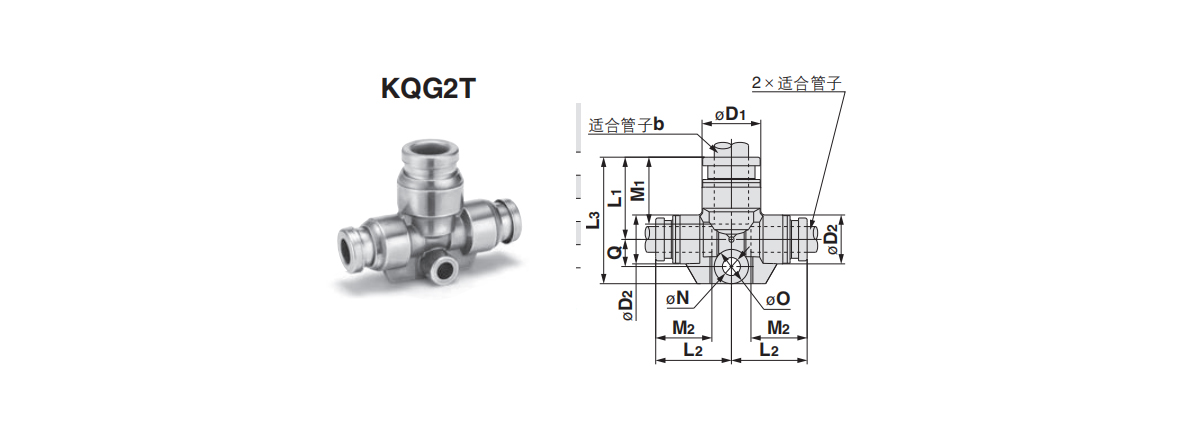

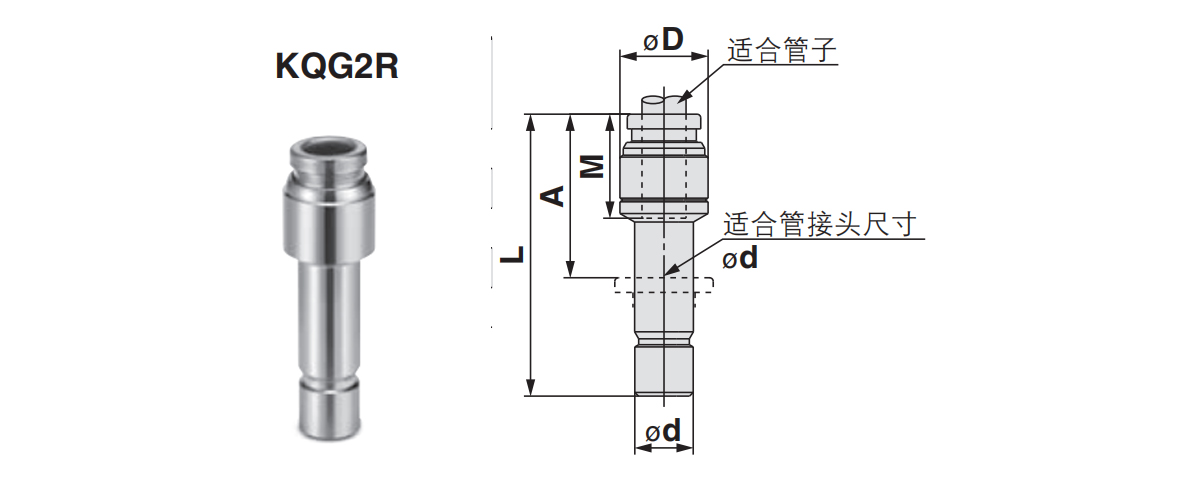

Modular compatible architecture

The standardized interface supports interchangeable adaptation with mainstream industrial pipe fittings, providing multiple topological variants such as straight-through, right-angle, and three-way, to achieve rapid expansion and reconstruction of complex pipe network systems.