Thin Cylinder

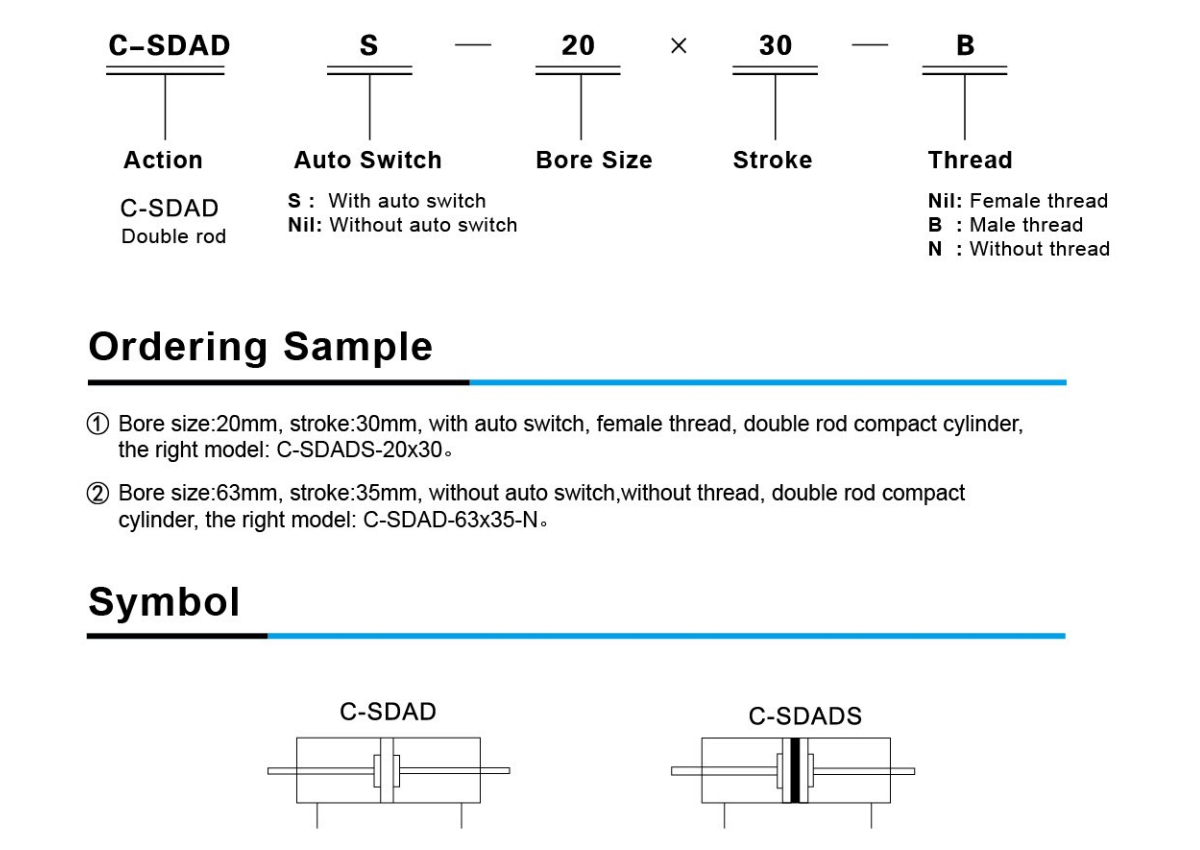

SDAD Series Thin Double-Axis Double-Acting Cylinder

SDAD Series Thin Double-Axis Double-Acting Cylinder is a compact pneumatic actuator with a thin box-type structure design and an integrated dual piston rod guide mechanism. It achieves linear reciprocating motion through bidirectional pneumatic drive. Its core feature is to solve the rigid output requirements under limited installation space conditions through physical space optimization and high-rigidity guide structure.

• Ultra-thin construction concept

The cylinder cross-section height is significantly compressed, and the structural depth is reduced by about 30%-50% compared to conventional cylinders. It is suitable for embedded installation or densely arranged scenes, effectively improving the space utilization of equipment.

• Double-axis anti-eccentric load mechanism

The two parallel piston rods form a torque suppression system, which simultaneously bears radial loads and overturning torques, improves the motion stability of the end effector under eccentric load conditions, and suppresses the risk of piston rod jamming.

• Bidirectional pneumatic double-acting mode

The standard configuration of the dual-port drive architecture realizes bidirectional equal force output of the piston rod through the control of the reversing valve. Both the forward and return strokes have full power output capabilities without the need for a return spring.

• High-rigidity rail integration

The guide shaft and cylinder body adopt an integral reinforced structure, and the motion swing is reduced by pre-load clearance elimination technology. The linear guide stiffness is about 2 times higher than that of the single-axis cylinder, ensuring the repeat positioning accuracy within the ±0.1mm tolerance band.

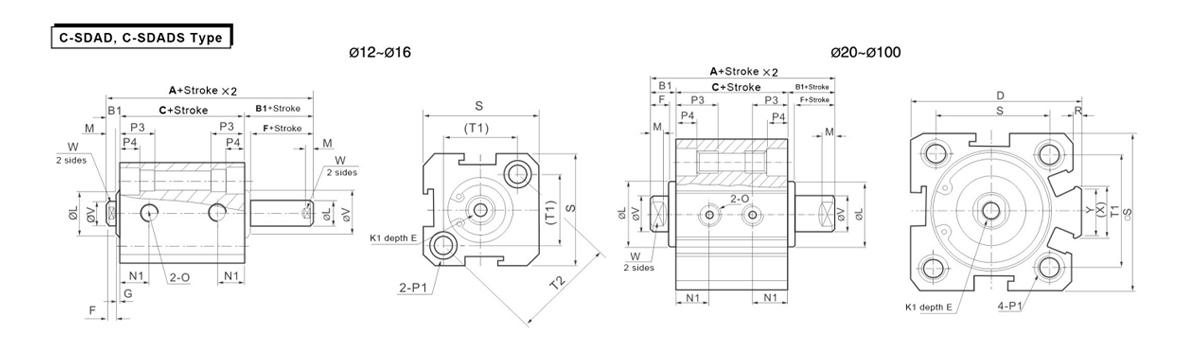

• Modular adapter interface

The piston rod end is compatible with ISO standard floating joints, and the cylinder body is preset with multi-axial mounting threaded holes and rail assembly surfaces. It supports non-standard configurations such as inverted installation and side-mounted installation, which is easy to integrate into the automation module.

• Dynamic response optimization

The small cavity structure shortens the airflow charging and discharging path, and cooperates with low-friction sealing components to achieve full stroke action time control in the range of 0.1-0.3 seconds (depending on the stroke specification), meeting the medium and high speed beat requirements.