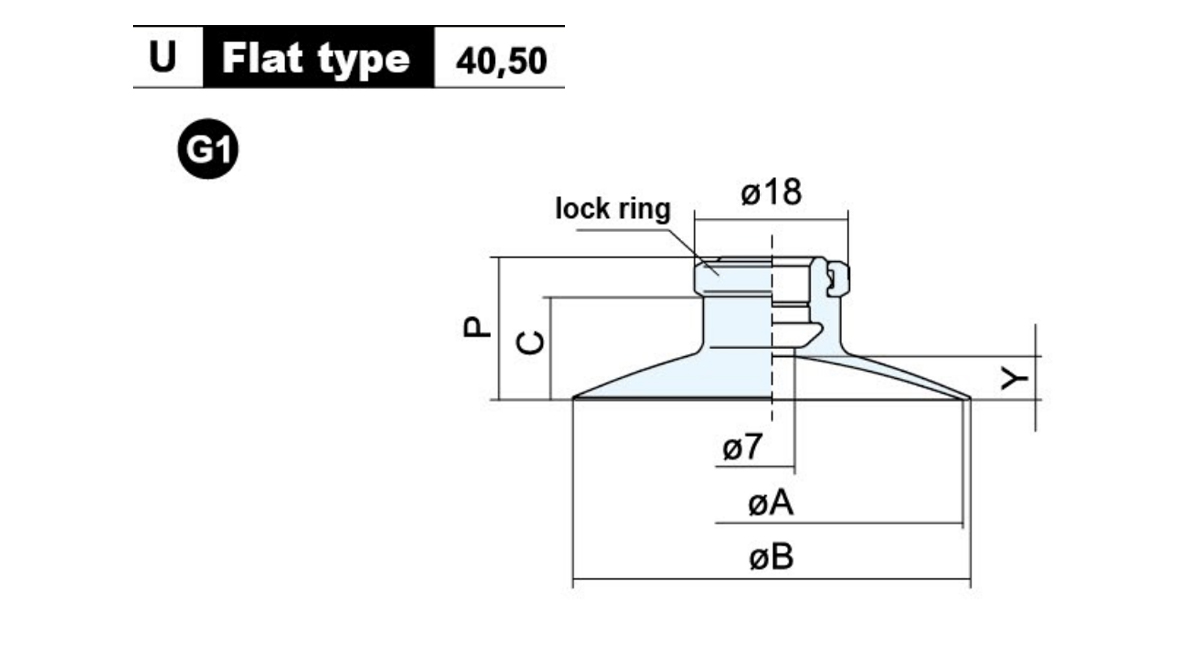

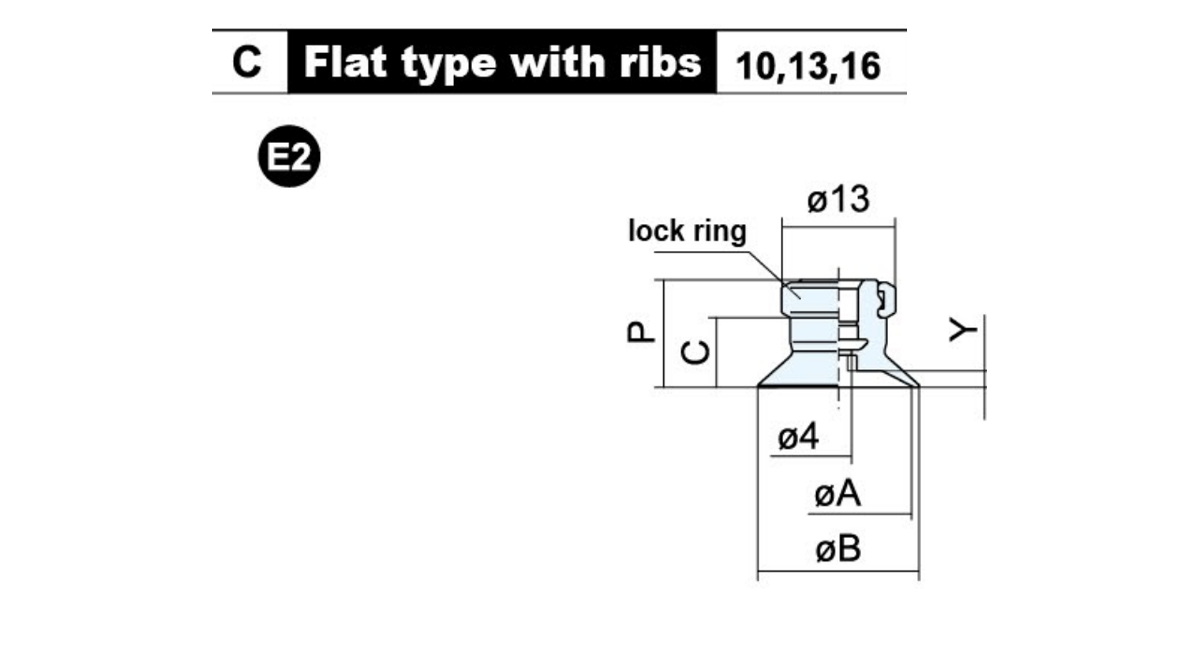

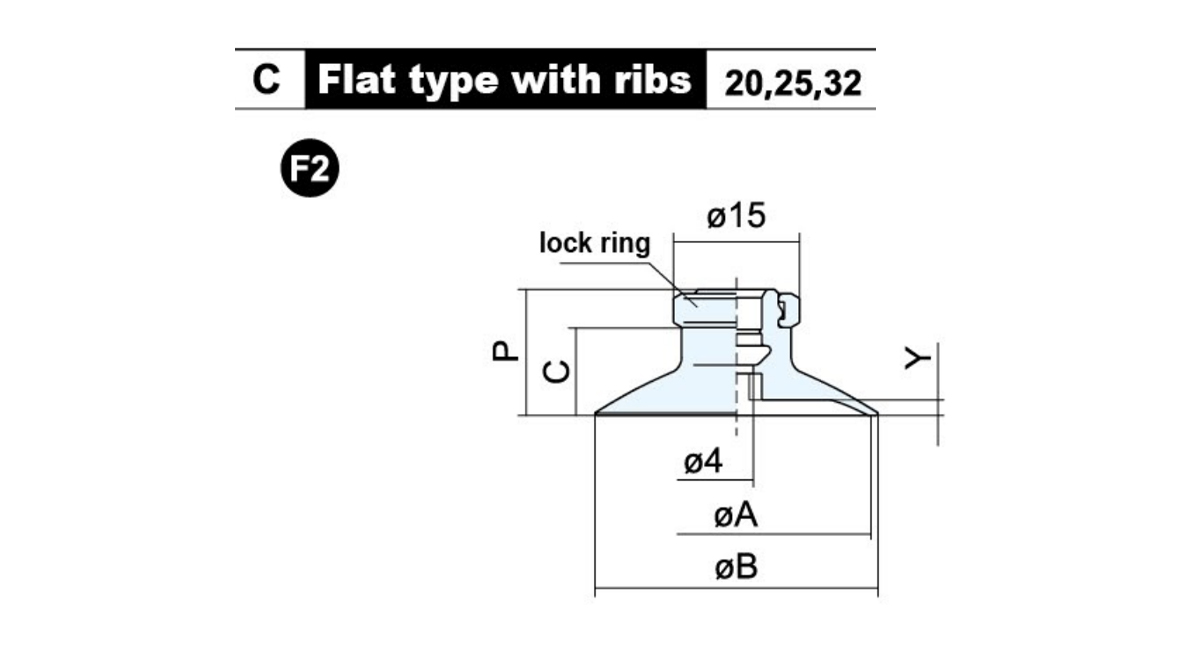

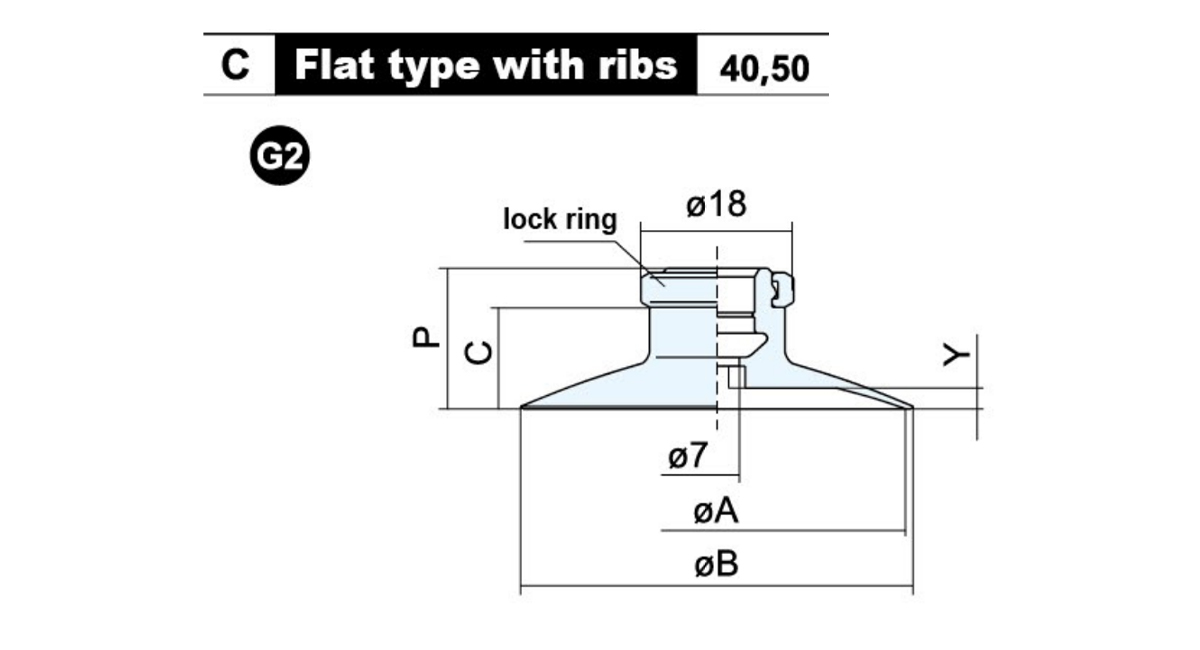

ZP Series Vacuum Suction Cup With Locking Ring, Adapter & Buffer Bracket

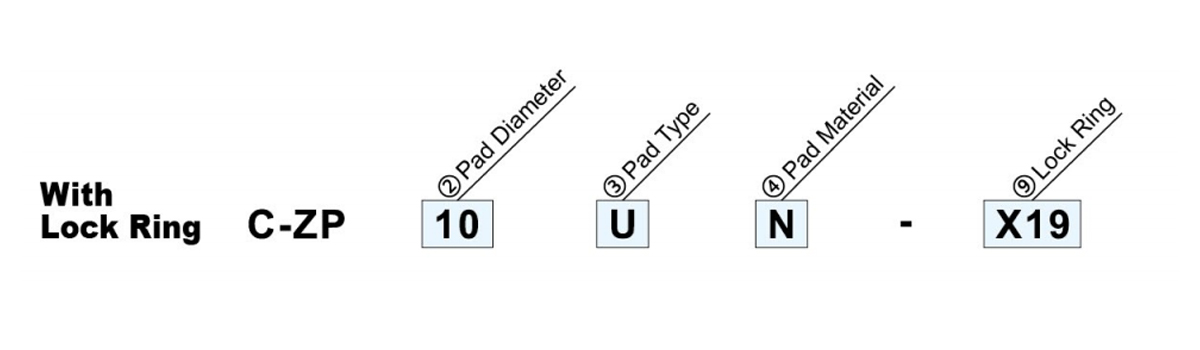

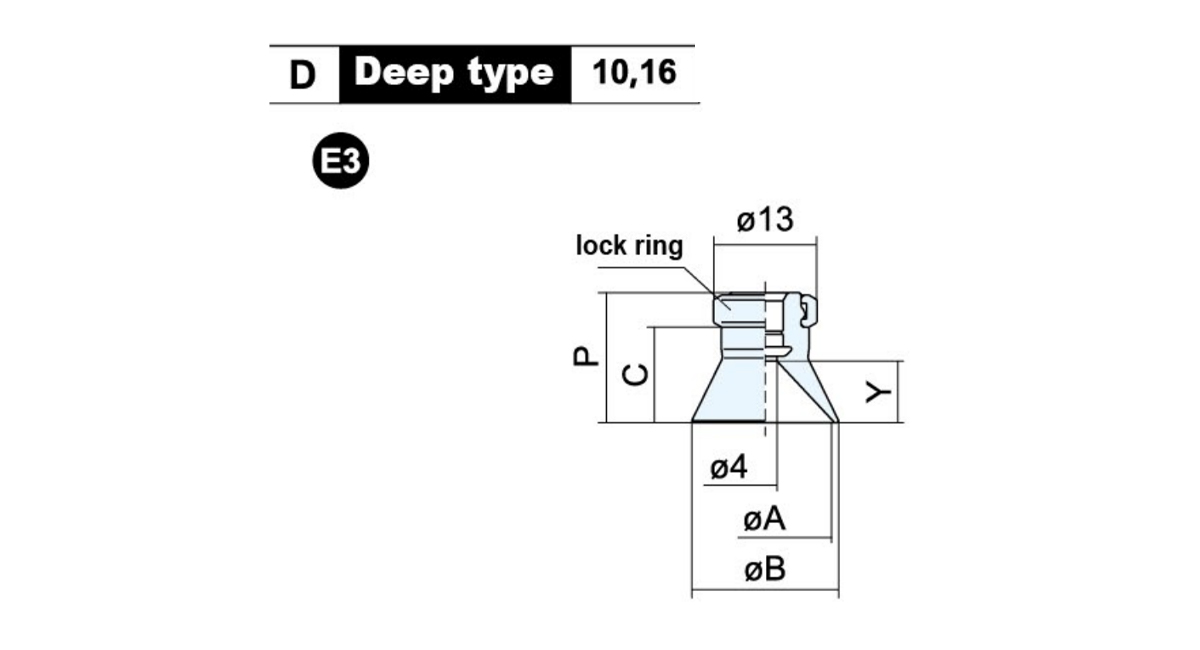

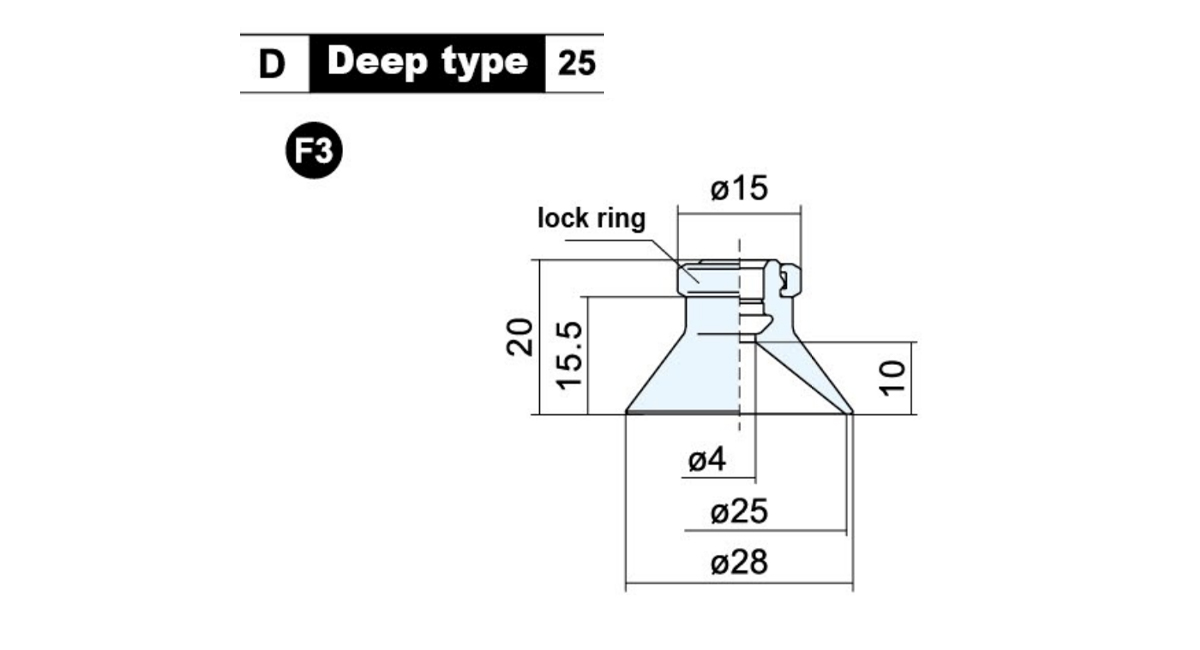

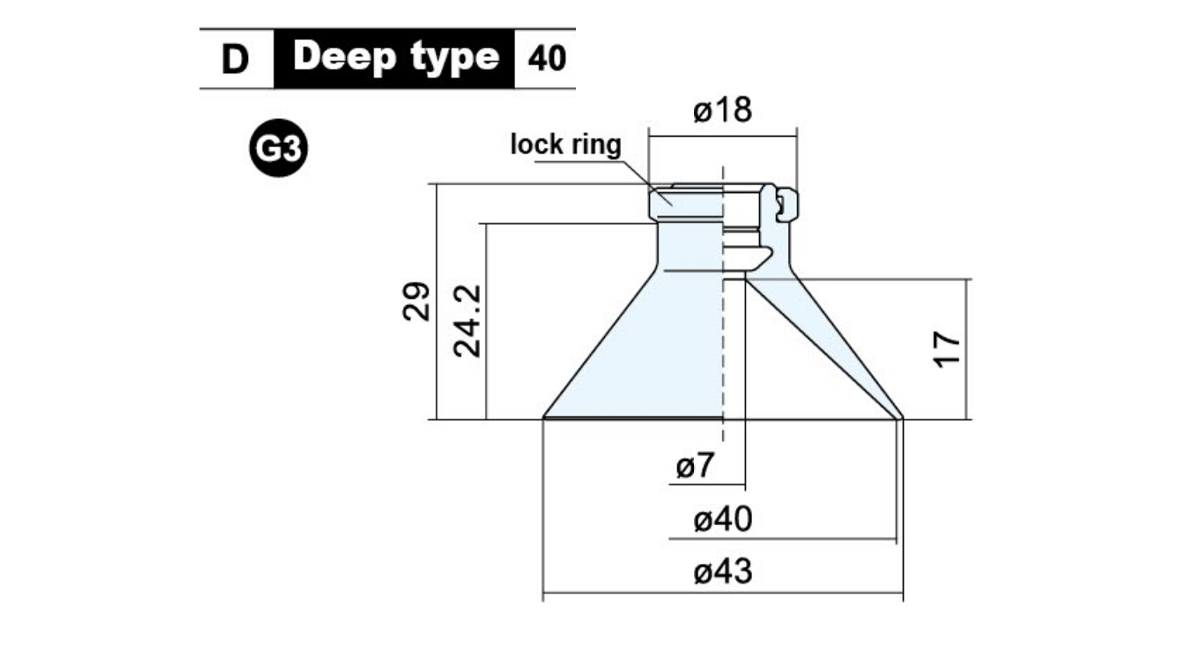

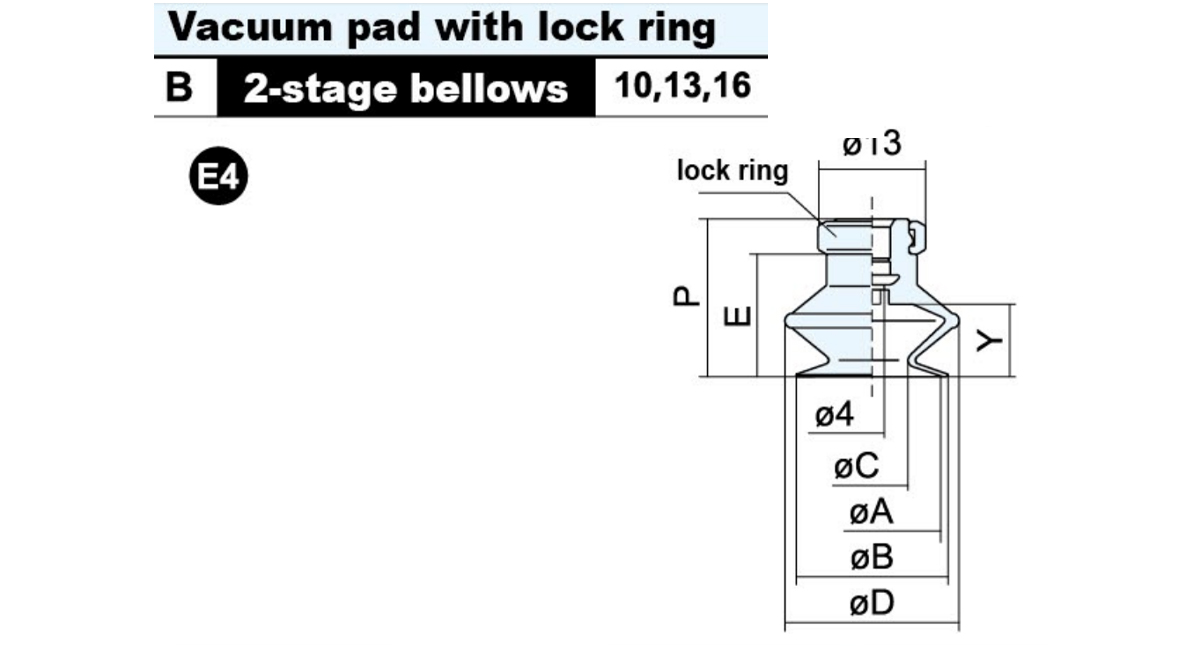

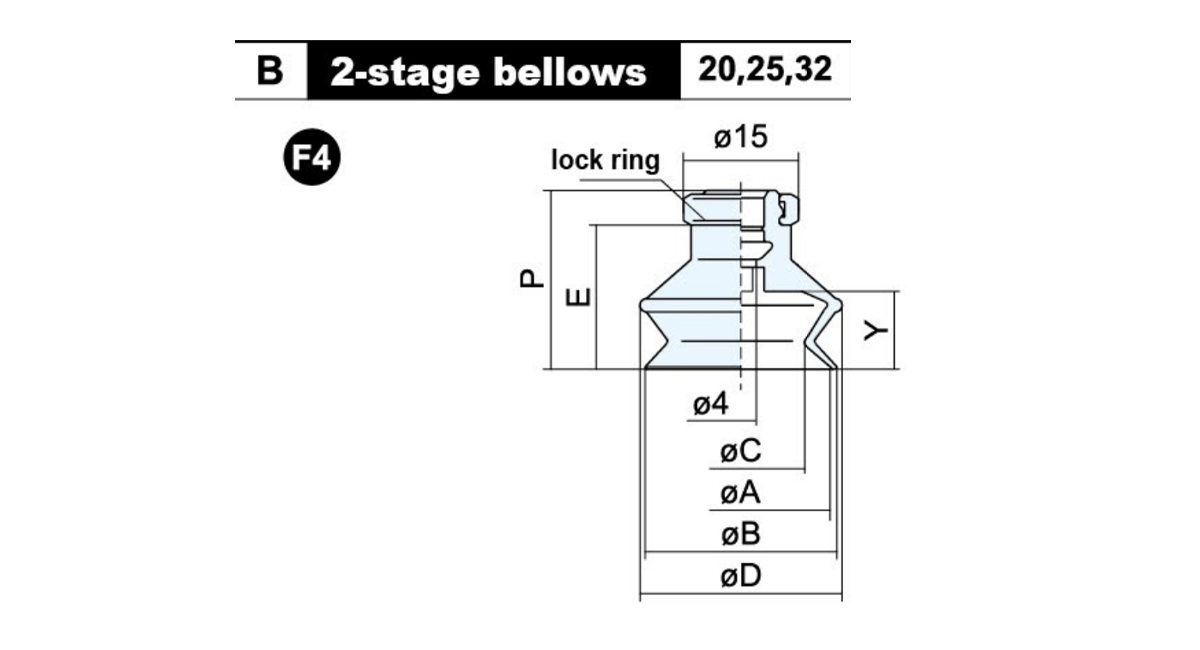

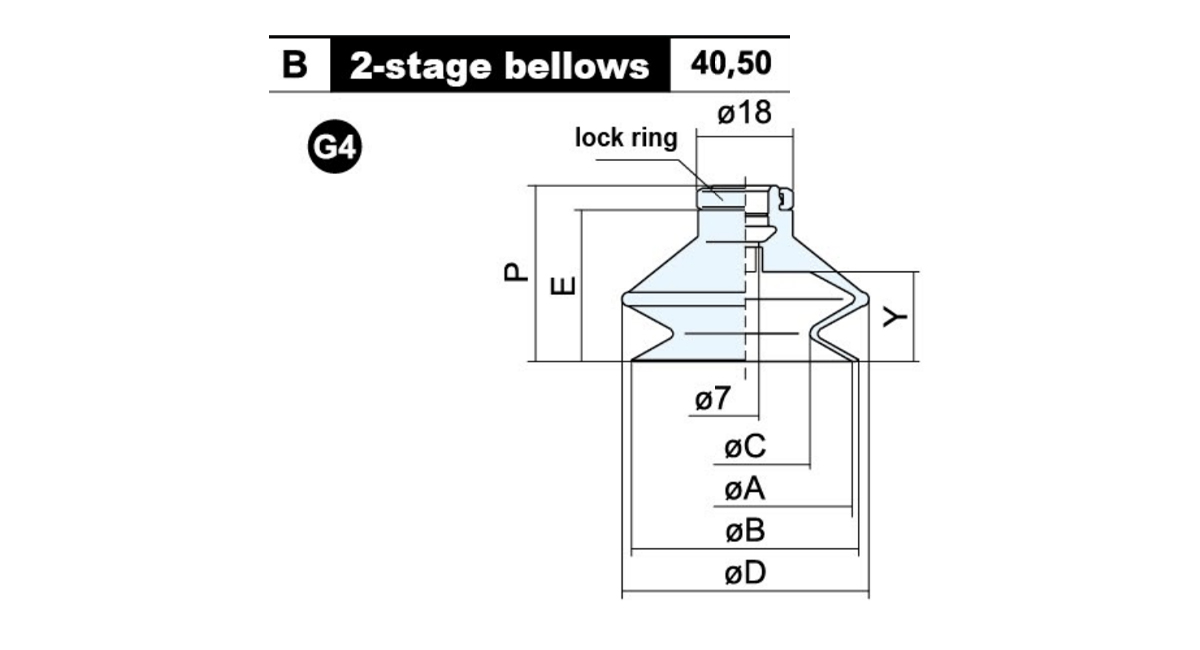

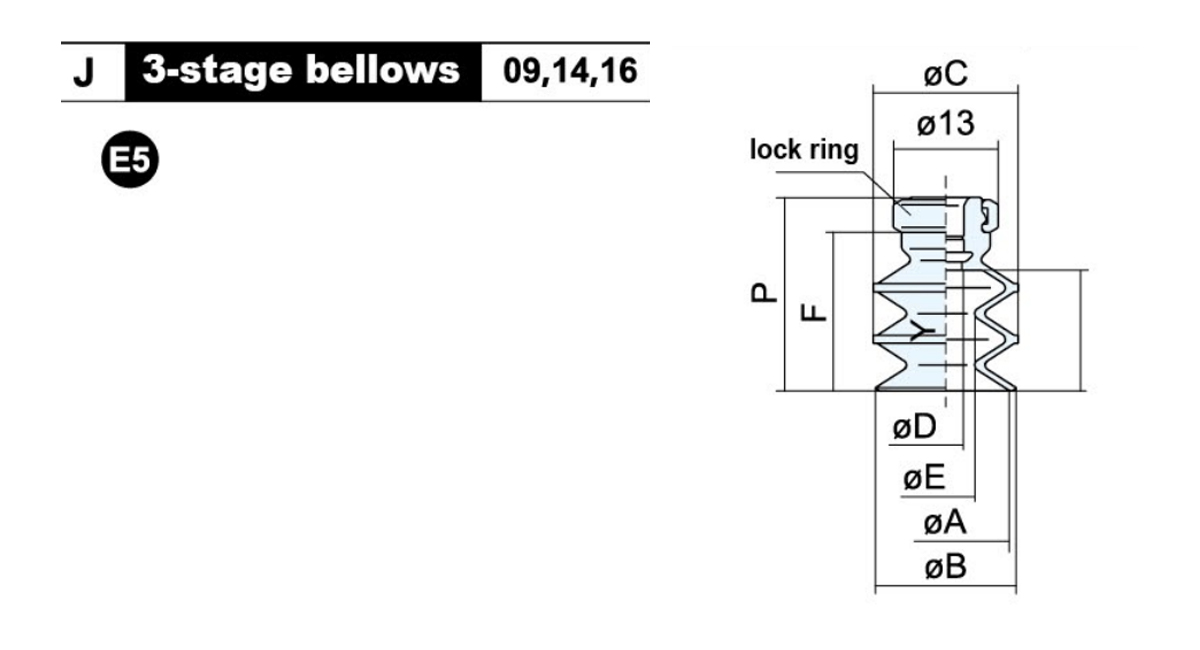

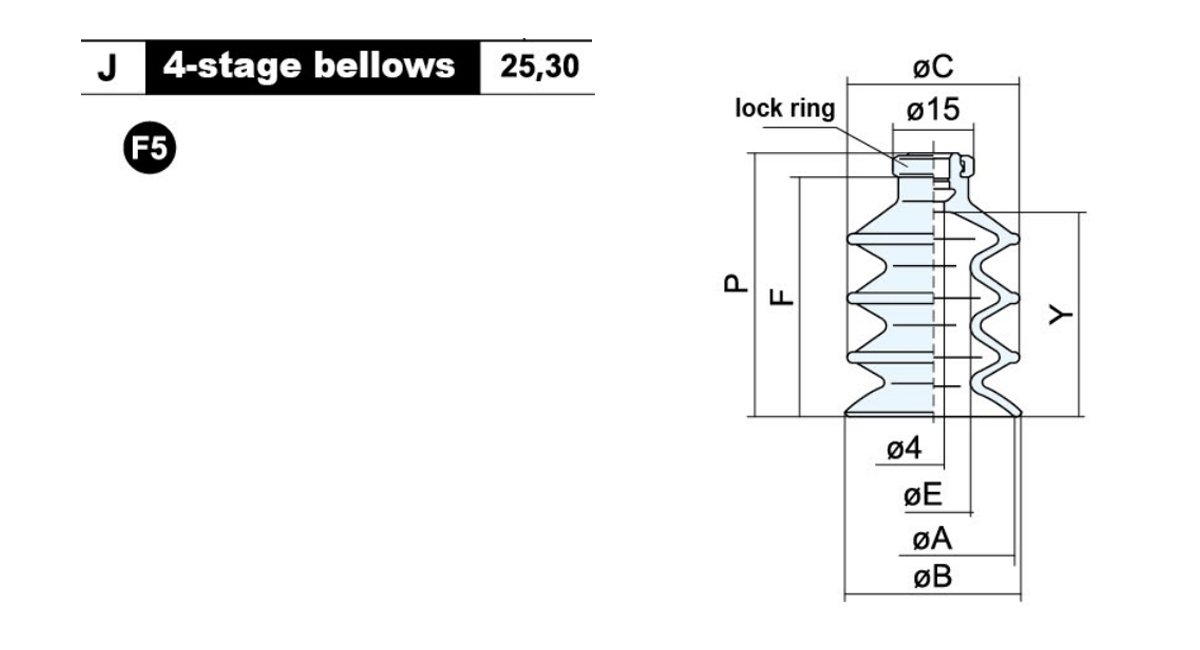

ZP Series Vacuum Suction Cup With Lock Ring (Ø9~Ø50)

ZP Series Vacuum Suction Cup With Lock Ring (Ø9~Ø50) is a core component designed to improve the stability of vacuum gripping. Its unique annular lock ring structure can effectively constrain the freedom of the workpiece during the adsorption process, providing reliable adsorption protection for various automated handling and precision positioning scenarios.

Core features:

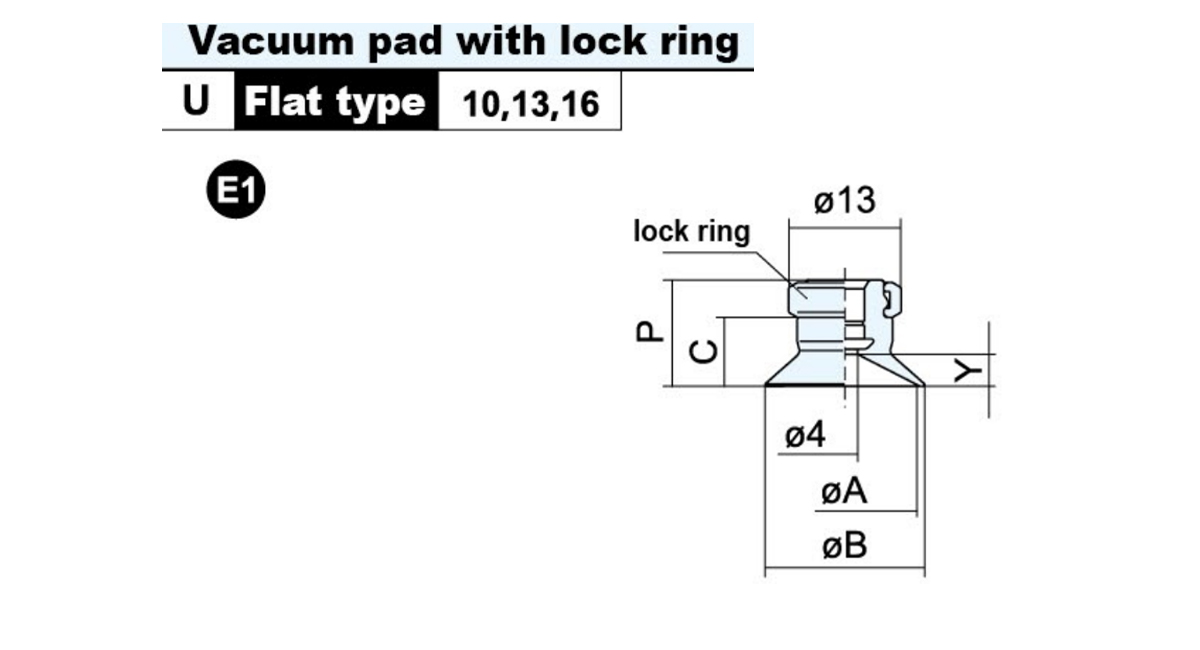

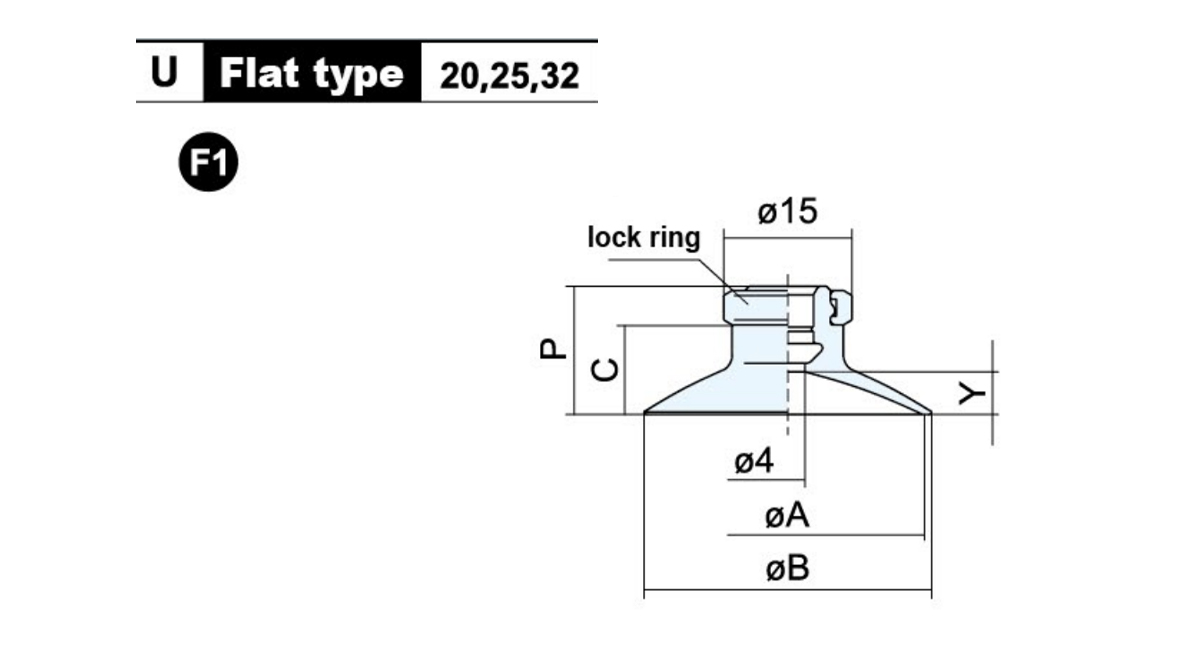

Locking adsorption mechanism: The unique annular lock ring design forms a physical constraint in the working state, significantly suppresses the deviation or rotation tendency of the workpiece when it is subjected to force, and improves the directional stability of the grasping process.

Enhanced adsorption reliability: The lock ring structure cooperates with the vacuum negative pressure to form a double protection mechanism, effectively resisting external disturbances (such as acceleration, vibration, and slight collisions) and reducing the potential risk of accidental detachment.

Flexible contact and sealing: The suction cup body is usually made of specific elastic materials to ensure adaptive fit with the surface of the workpiece, forming an effective vacuum seal, and adapting to slight surface fluctuations.

Optimized for thin/small objects: This series of size range (Ø9~Ø50) is particularly suitable for grasping thin plate materials, small precision parts or lightweight workpieces with smooth surfaces. The locking ring structure is particularly critical for such workpieces that are easily displaced or affected by airflow.

Engineering application universality: It is widely used in scenarios requiring directional fixation or anti-rotation handling, commonly used in electronic component assembly, small injection molding parts sorting, thin sheet material (metal/non-metal) conveying, packaging automation and other process links.

Specifications cover common needs: The diameter range provided covers the common small to medium-sized workpiece grasping size standards in the automation field, which is convenient for engineering selection and matching.