Combined Vacuum Generator

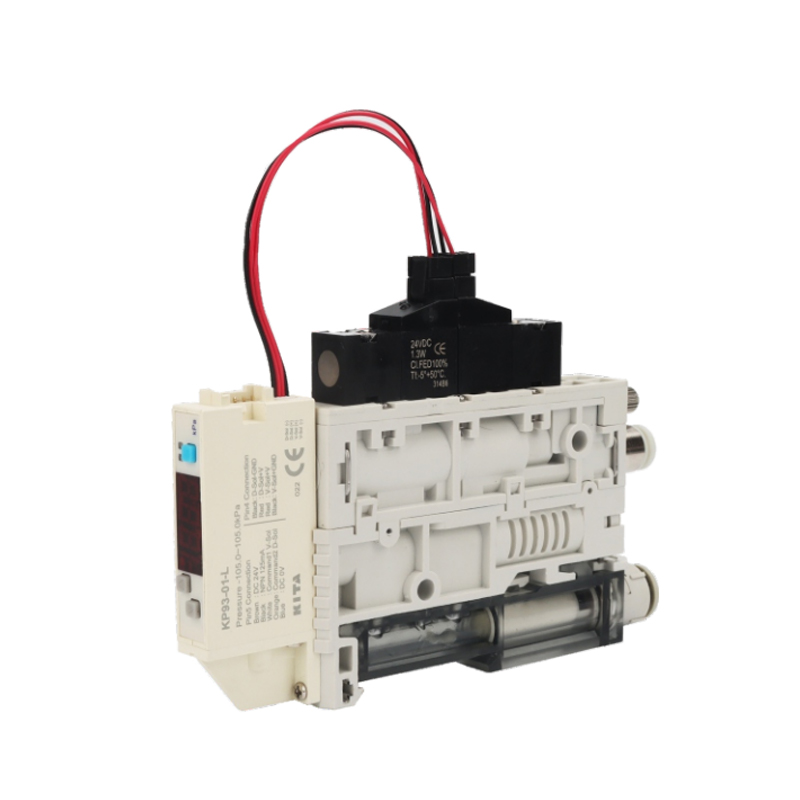

ZK2 Series Vacuum Unit/Vacuum Generator

ZK2 Series Vacuum Unit/Vacuum Generator is an innovative pneumatic device that integrates high efficiency, energy saving and compact design. It is designed for vacuum adsorption in industrial automation scenarios. Through digital control and structural optimization, it significantly improves vacuum performance while reducing energy consumption. It is suitable for modern production lines that are sensitive to efficiency and cost.

Product Features

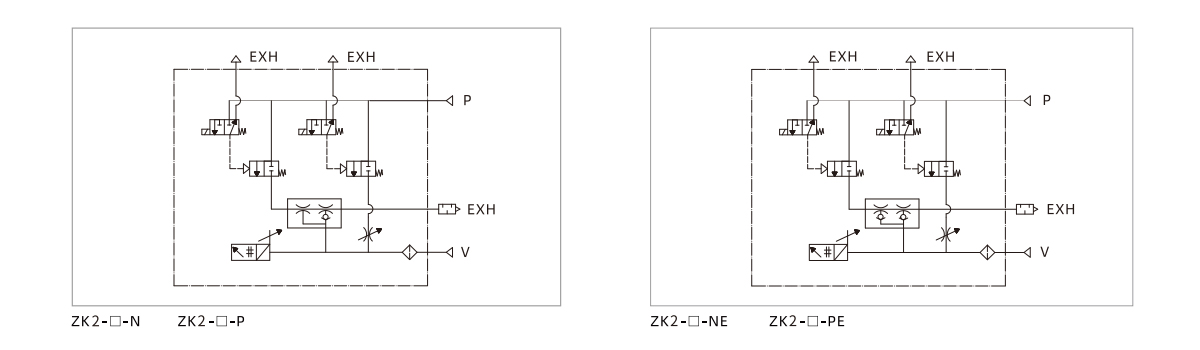

1. Ultra-low air consumption: As an energy-saving vacuum generator, its air consumption is reduced by 90% compared with traditional Models. It is equipped with a vacuum digital pressure switch. When the vacuum degree reaches the set value, it automatically stops supplying air, greatly reducing operating costs.

2. Efficient vacuum generation: Compared with a one-stage vacuum generator, the suction flow rate is increased by 50%, and the air consumption is reduced by 30%, achieving a faster and more stable vacuum adsorption effect.

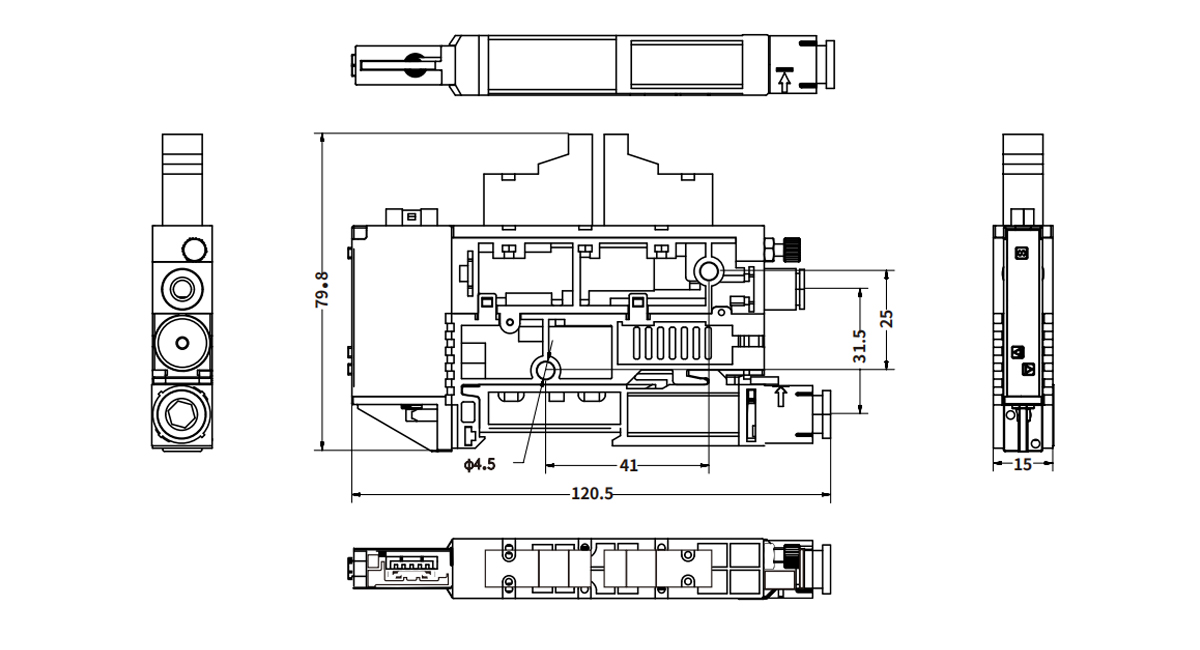

3. Extremely compact design: With a volume of only 85cm³ and a weight of 90g, it is a Model of lightweight and miniaturization among similar products, especially suitable for installation environments with limited space.

4. Convenient maintenance design: The transparent filter cover can be used to visually check the internal cleanliness status; the cover supports quick disassembly to simplify the cleaning and maintenance process.

5. Flexible installation method: supports single bracket installation, single DIN rail installation and containerized DIN rail installation to meet the needs of diversified equipment integration.

6. Save wiring costs: standard D-type auxiliary plug, reduce piping, wiring and setting hours, and improve system construction efficiency.