Rodless Cylinder

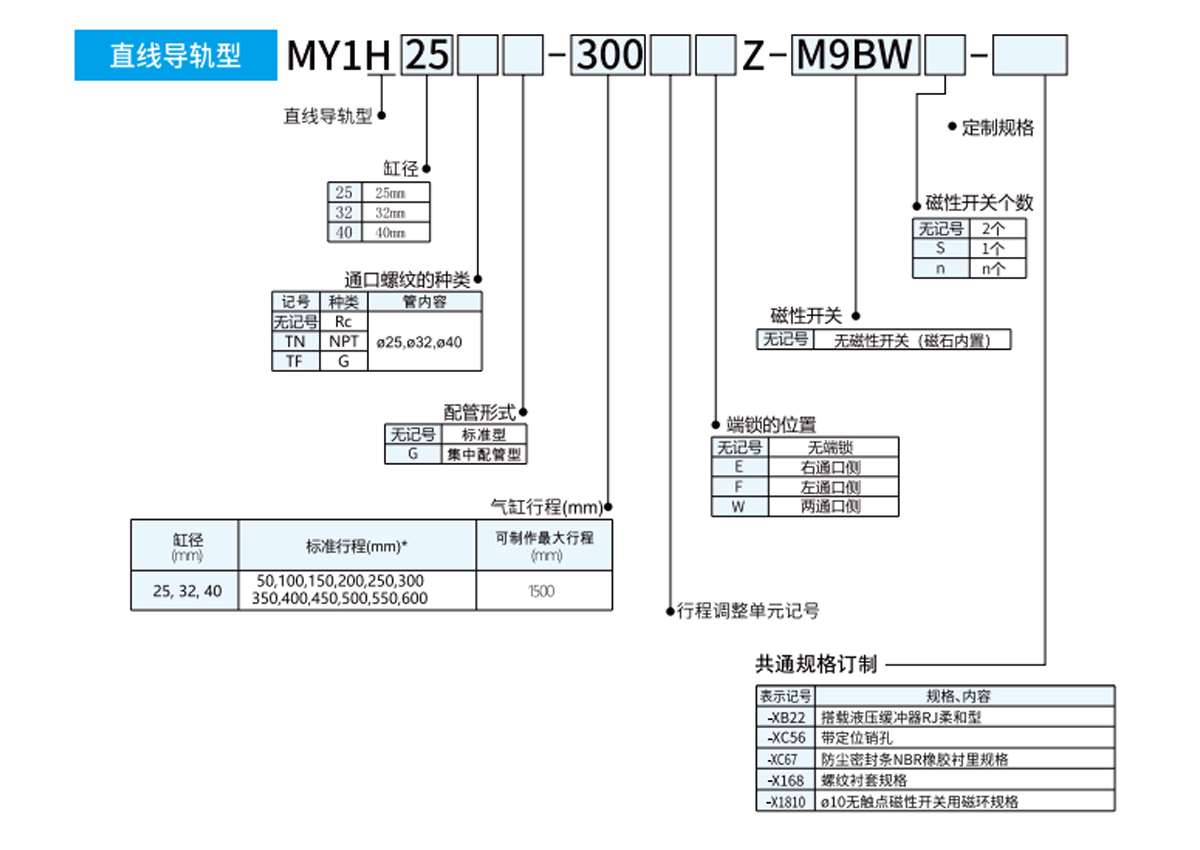

MY1H Series Mechanically Jointed Rodless Cylinder (Linear Guide Type)

MY1H Series Mechanically Jointed Rodless Cylinder is a rodless cylinder that uses mechanical joints to achieve motion transmission, and is specially integrated with a linear guide structure. It focuses on providing a compact, reliable and precision-satisfying linear drive solution for common pick-and-place applications in automation systems.

● Core driving force type: Its core lies in the unique mechanical joint structure, which cleverly transmits the linear motion of the piston directly to the external load slide through the internal mechanism, without the need for the piston rod extension of the traditional cylinder, and realizes the compact integration of the cylinder body and the load movement.

● Precision guide cornerstone: In contrast to conventional Models, this series has a built-in high-rigidity linear guide system. This provides support and guidance for the load slide that far exceeds the guiding capability of the cylinder itself, significantly improves the smoothness of movement, and brings higher repeatability, which is suitable for positioning occasions with moderate precision requirements.

● Typical application positioning: The designed load capacity and travel range of this series make it very suitable for frequent picking, transfer and placement operations of small and medium-sized workpieces with moderate weight on automated production lines. It is especially suitable for scenarios where the workpiece size range is in the typical small and medium specifications (for example, the diameter is in the tens of millimeters level).

● Space efficiency advantage: Since the front and rear space required for piston rod extension and retraction is eliminated, combined with its integrated guide rail design, the overall structure is very compact, which is particularly conducive to saving valuable axial installation space in space-constrained equipment layout.

● Reliability considerations: Mechanical coupling design usually means less sliding seal requirements (compared to magnetic coupling), which can improve service life and reduce dependence on maintenance to a certain extent, and the operation is more reliable.