Rodless Cylinder

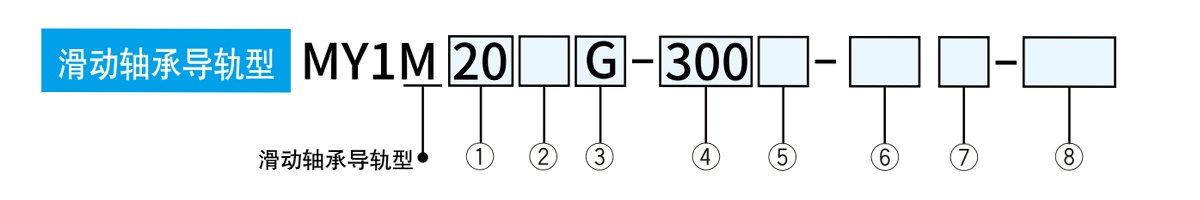

MY1M Series Mechanically Jointed Rodless Cylinder Sliding Bearing Guide Type

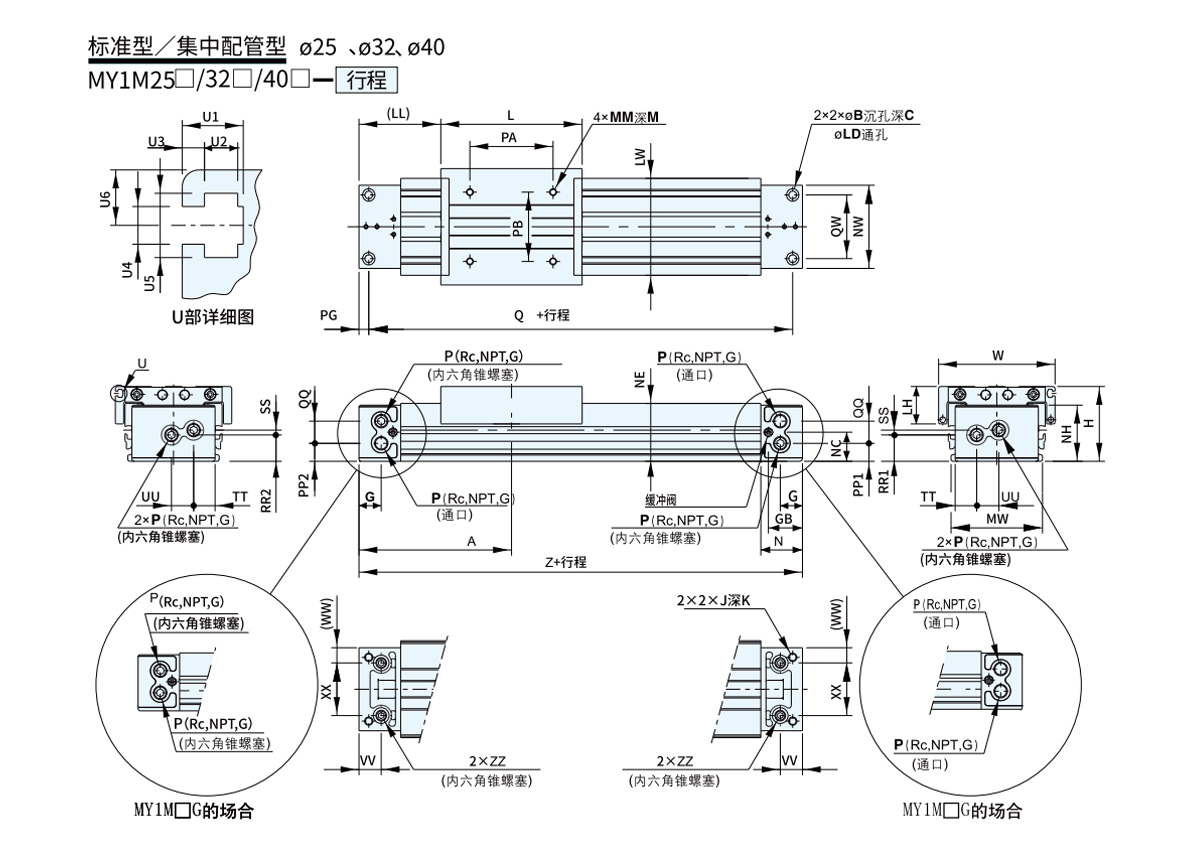

MY1M Series Mechanically Jointed Rodless Cylinder Sliding Bearing Guide Type adopts an integrated structure of mechanically jointed rodless cylinder and sliding bearing guide rail, which simplifies the mechanical configuration of the linear motion system by directly integrating the load transmission path and the guide mechanism. Its compact design is particularly suitable for simple linear drive scenarios where workpieces need to be directly mounted on the mover, and it also has structural adaptability to cope with a wide range of handling tasks.

Overview of core features

■ Integrated guide rail design

The cylinder body and the sliding bearing guide rail form a physical fusion unit, eliminating the assembly link of the traditional cylinder and independent guide rail. This structural fusion significantly reduces system complexity and makes the equipment layout more compact, especially suitable for space-constrained automation units.

■ Low-friction guide characteristics

The sliding bearing guide rail provides stable low-resistance linear guidance, balancing load capacity and running smoothness through optimized friction pair design. This guide form can effectively suppress vibration drift under normal working conditions and ensure the geometric consistency of the load movement trajectory.

■ Direct workpiece mounting capability

The mover table is specially strengthened to allow users to directly fasten small and medium-sized workpieces or fixtures. This eliminates transitional components such as secondary mounting plates, shortens the force transmission chain, and improves system rigidity and positioning response speed.

■ Large stroke adaptability

The mechanically coupled transmission breaks through the physical limitations of the piston rod and has the ability to expand to a longer linear stroke while maintaining the size of the cylinder body. The structural characteristics of the full-range support of the guide rail ensure the movement stability of the load within a larger stroke range.

■ Handling scenario optimization

The high rigidity and load adaptability brought by the integrated guide rail make it outstanding in continuous handling scenarios such as material transfer and component transfer. The system can be configured to operate horizontally or vertically to meet the needs of material transfer across stations and modules.