Rodless Cylinder

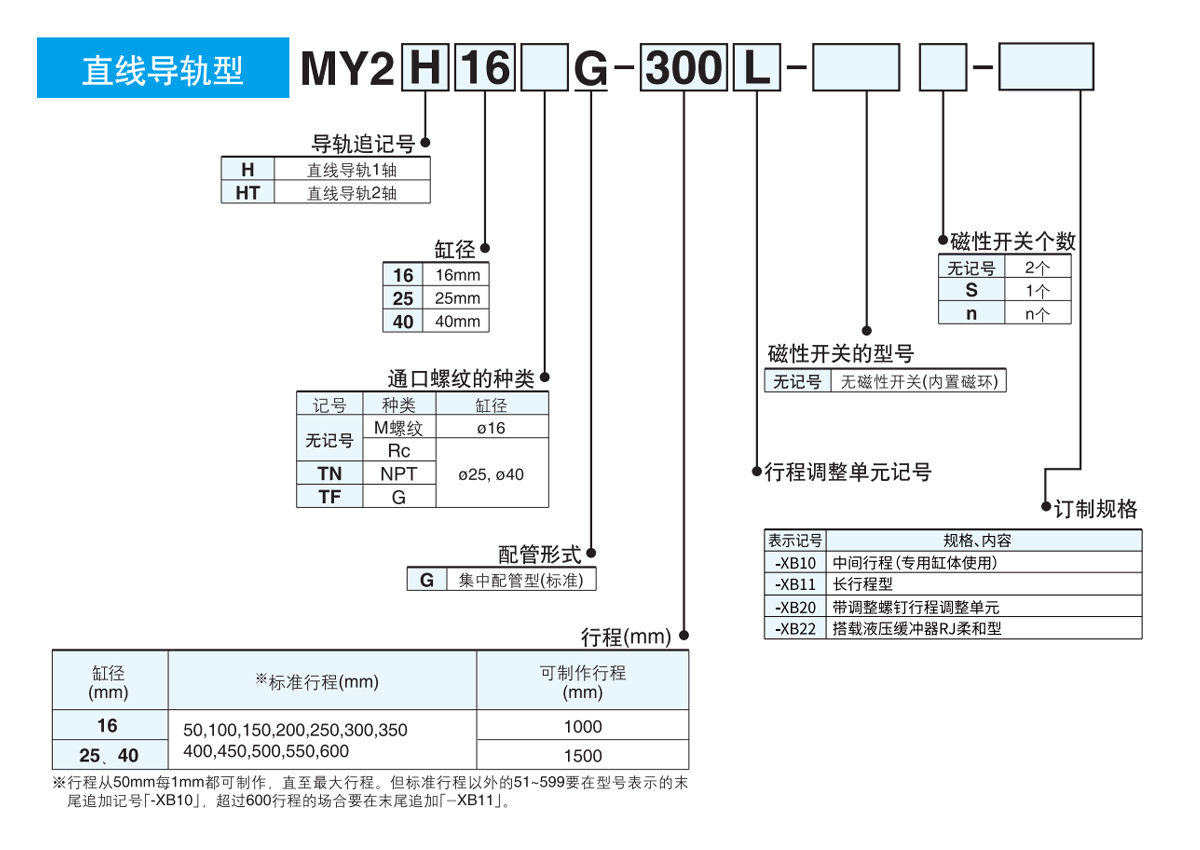

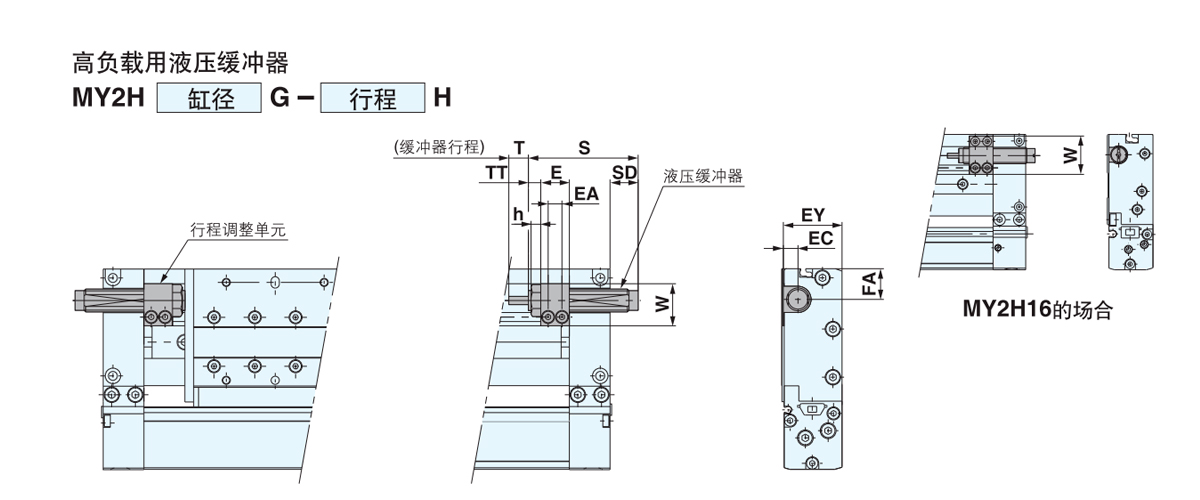

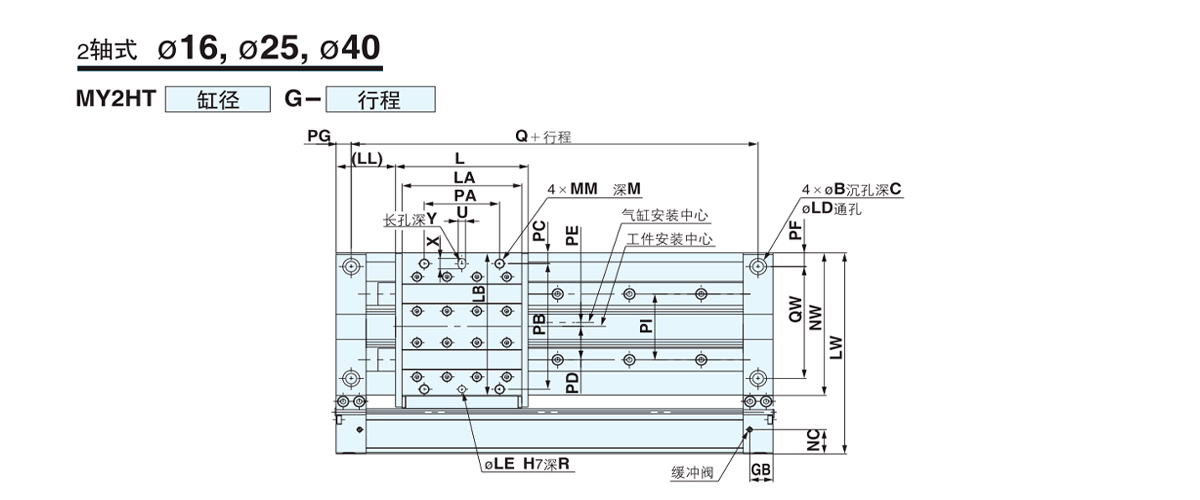

MY2H/HT Series Mechanical Joint Rodless Cylinder Linear Guide Type (1 Axis)/Linear Guide Type (2 Axes)

MY2H/HT Series Mechanical Joint Rodless Cylinder Linear Guide Type (1 Axis)/Linear Guide Type (2 Axes) is an integrated motion component designed for space-constrained working conditions. It realizes rodless linkage between the slider and the cylinder body through mechanical joint technology, and optimizes load guidance performance in combination with linear guide structure, which is suitable for precision transfer and high-rigidity positioning scenarios.

The main features are described as follows:

1. Differentiated design of guide rail structure

• MY2H type (single-axis guide): Equipped with a high-precision linear guide system to eliminate radial clearance during movement and ensure high repeatability positioning when lightweight workpieces are transferred.

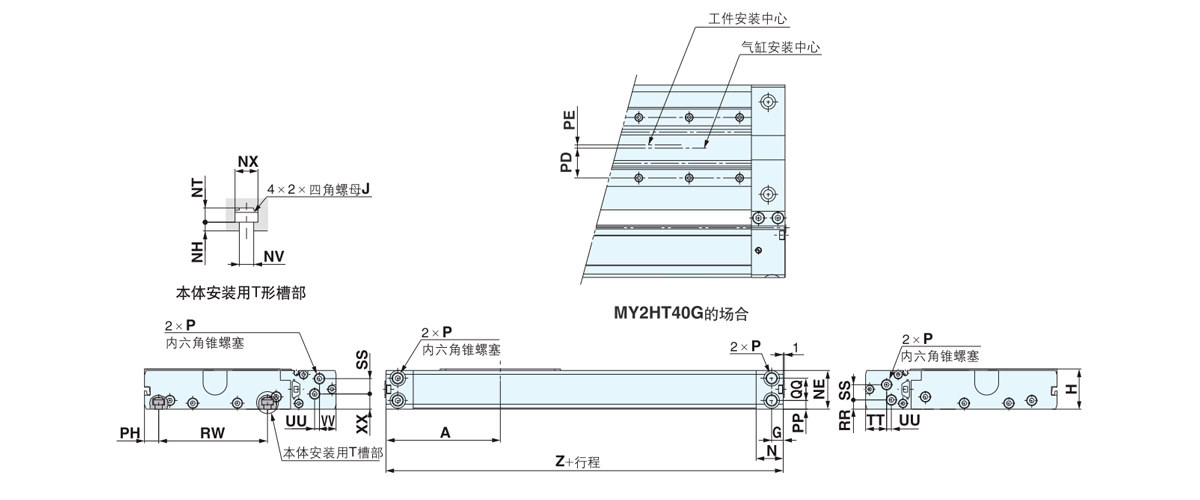

• HT type (dual-axis guide): Adopts a parallel dual-guide structure to form a stable support surface by increasing the span, effectively suppressing the load deflection torque and enhancing rigidity performance.

2. Dynamic floating compensation mechanism

The dual-guide structure has a built-in dynamic centering mechanism, which can adaptively absorb the slight unevenness of the installation surface, avoid abnormal wear caused by uneven force on the guide rail, and extend the service life.

3. Load characteristic graded adaptation

• Precision operation of light workpieces: The single-axis Model is suitable for micro-force pick-and-place operations in electronic assembly and testing equipment due to its low-friction guide rail characteristics.

• Stability under high load conditions: The dual-axis Model disperses the load-bearing stress to meet the rigid conveying requirements of heavy-loaded objects such as metal workpieces and multi-station fixtures.

4. Enhanced anti-deflection capability

The dual-axis guide rail topology significantly improves the ability to resist end-end rollover torque, especially overcoming the risk of slider overturning in long-stroke applications, and ensuring the accuracy of the transfer trajectory of large-size workpieces.