Thin Cylinder

SDAT Series Thin Multi-position Cylinder

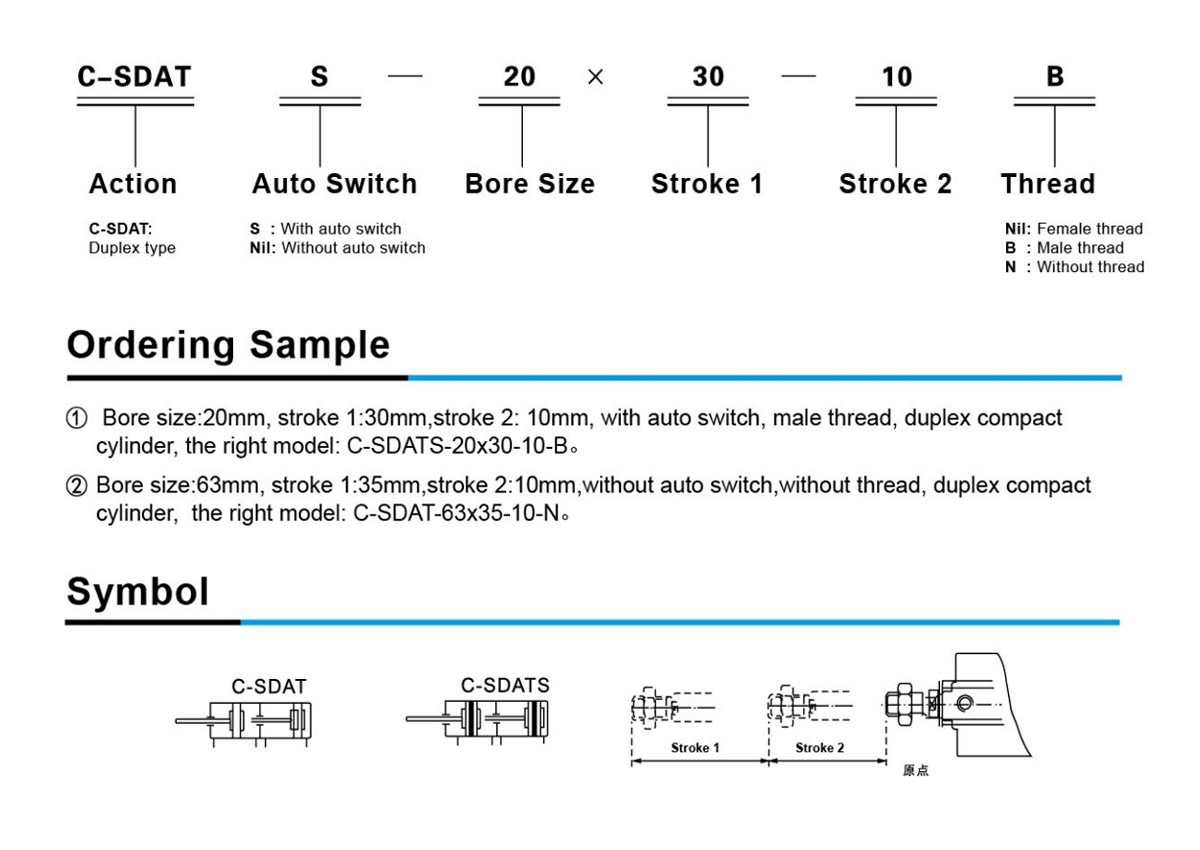

SDAT Series Thin Multi-position Cylinder represents a type of industrial cylinder whose design concept focuses on space saving and multi-point positioning capabilities. Its core feature is that while the structure is highly compressed, it breaks through the limitation of the traditional single cylinder single stroke, giving the execution end the ability to accurately stop between multiple preset stations, which is particularly suitable for automation scenarios with compact layout and step-by-step operation.

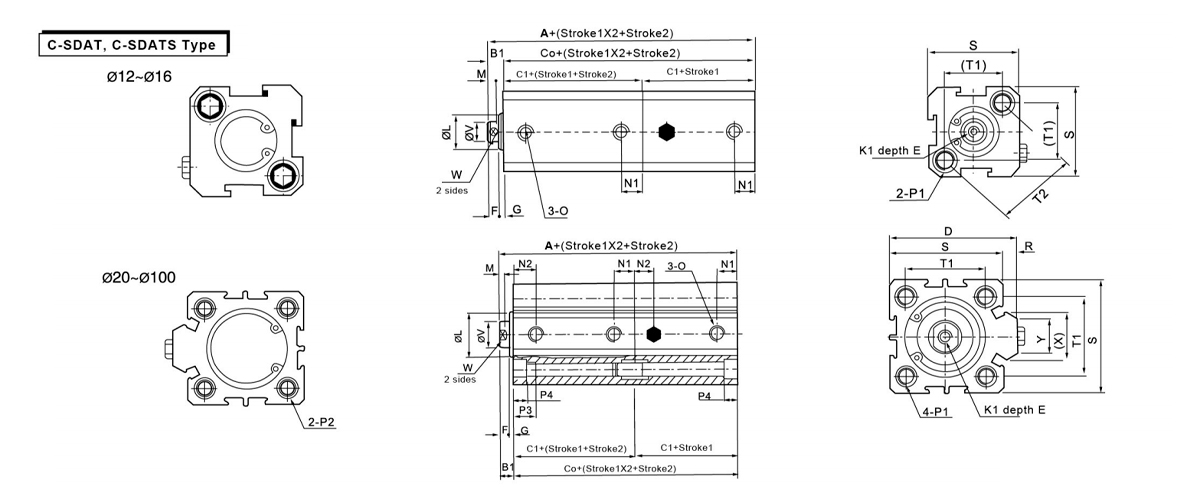

• Extremely thin: Significantly different from the heavy profile of standard cylinders, this series has achieved deep optimization in the axial dimension of the cylinder body, showing an unusually flat overall structural feature, which greatly reduces the requirements for installation space.

• Multi-station integration: The core design essence lies in the integration of the functional architecture of non-single posture positioning. The drive output shaft can achieve accurate and stable parking at several preset discrete positions to meet the automation requirements of process segmentation or posture change.

• Compact space adaptability: The low-profile structure allows it to be easily embedded in the inside of a robotic arm, a narrow cavity or a densely arranged equipment array, effectively solving the layout problem caused by the volume limitation of traditional cylinders.

•High rigidity structural features: Despite its slim shape, its cylinder and internal components are usually designed to strengthen the anti-torsion design, aiming to withstand possible lateral loads or torque interference, ensuring positioning accuracy and long-term operational reliability.

•Dynamic response characteristics: The optimized flow channel and sealing system strive to achieve relatively fast start, stop and position switching response in a limited space, which meets the general requirements of modern automation for rhythm.

•Modular adaptation tendency: As a standardized industrial component, its installation interface and dimensional parameters follow general specifications, showing good compatibility with peripheral systems, and easy to integrate into various pneumatic circuits and control frameworks.