In industrial automation, packaging machinery, and production line equipment, pneumatic components are widely used due to their simple structure, fast response, and low cost. However, during long-term operation, pneumatic systems inevitably experience various malfunctions, affecting equipment stability and production efficiency. Understanding the common malfunctions of pneumatic components and their causes is key to improving equipment reliability and reducing downtime.

1. Common Types of Pneumatic Component Malfunctions

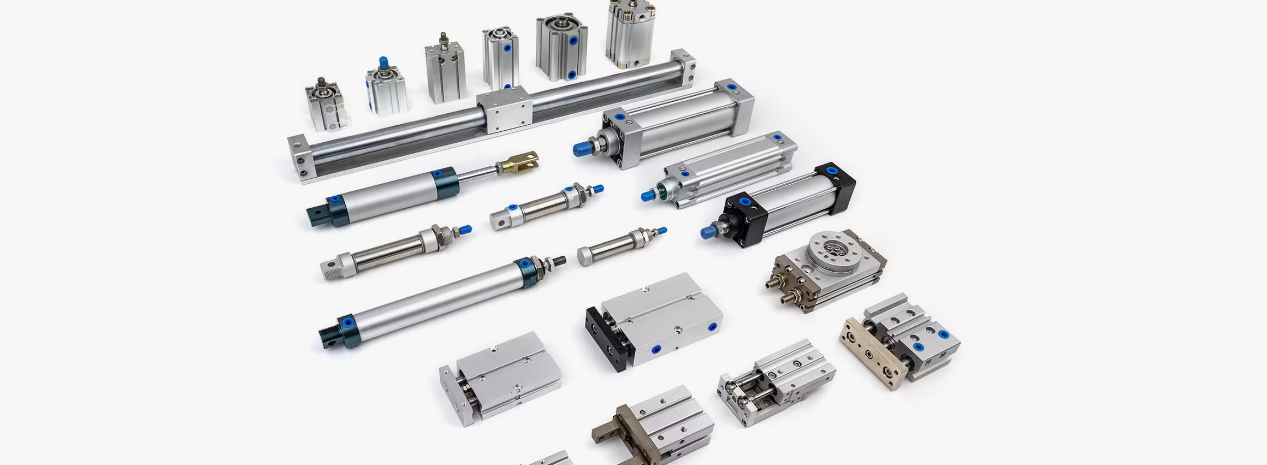

Pneumatic components mainly include cylinders, solenoid valves, air source treatment components (filters, pressure regulators, lubricators), and air pipes. Their common malfunctions can be broadly classified into the following categories.

(1) Abnormal Cylinder Operation

Symptoms:

Cylinder does not move or moves slowly

Stroke is incomplete or movement is unstable

Common Causes:

Insufficient or excessive fluctuation of air pressure

Worn or aged cylinder seals

Increased resistance due to dust or water ingress into the cylinder

Solutions:

Check if the air pressure is stable

Replace aged seals

Strengthen air source filtration and daily cleaning

(2) Solenoid Valve Malfunction

Symptoms:

Valve does not respond after power is applied

Valve core is stuck, switching is not sensitive

Common Causes:

Coil burnout or unstable voltage

Impurities in the air source causing the valve core to seize

Internal wear due to long-term operation

Solutions:

Check power supply and voltage matching

Clean or replace the solenoid valve

Install a filter to improve air source quality

(3) Air Source Treatment Component Failure

Symptoms:

Unstable system pressure

High moisture content in the air source

Common Causes:

Filter blockage

Pressure regulating valve malfunction

Failure to drain in time leading to moisture entering the system

Solutions:

Regularly clean or replace filter elements

Calibrate or replace the pressure regulating valve

Drain regularly to keep the air source dry

2. Air Leakage in the Pneumatic System

Symptoms:

System pressure drops

Air pump starts frequently

Energy consumption increases significantly

Common Causes:

Aged or damaged air pipes

Loose connectors or damaged seals

Improper installation leading to loose connections

Solutions:

Check and replace aged air pipes

Tighten connectors and replace seals

Standardize installation procedures to avoid repeated disassembly and assembly

3. Slow Response of Pneumatic Components

Symptoms:

Delayed action

Unstable cycle time

Common Causes:

Excessively long or small diameter pipelines

Inappropriate selection of pneumatic components

Accumulation of impurities in the system

Solutions:

Optimize pipeline layout

Select appropriate specifications of pneumatic components

Regular maintenance and cleaning of the system

4. Shortened Lifespan of Pneumatic Components

Symptoms:

Frequent component replacement

Increased maintenance costs

Common Causes:

Long-term overpressure or overload operation

Poor air source quality

Lack of regular maintenance

Solutions:

Operate according to rated parameters

Improve air source filtration and drying

Establish a regular maintenance system

5. How to effectively reduce pneumatic component failures?

Improve air source quality

A dry, clean, and stable air source is the foundation for the long-term reliable operation of pneumatic components.

Proper Selection

Select appropriate pneumatic components based on load, speed, and working environment, avoiding undersizing the components for the application.

Standardized Installation

Avoid excessive bending of air pipes and ensure proper sealing.

Regular Inspection and Maintenance

Establish a regular inspection system to identify potential problems in advance.

Common failures in pneumatic components mainly occur in cylinders, solenoid valves, air treatment units, and piping systems. The root causes are often related to air supply quality, improper selection, and insufficient maintenance. Through scientific selection, standardized installation, and regular maintenance, the failure rate can be significantly reduced, improving the stability and service life of the pneumatic system and providing reliable support for industrial production.